Simplified rule-based strategy control for electric propulsion system

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

The current global trends regarding tightened environmental regulations on emissions from ships have motivated the development and usage of electric propulsion systems as alternatives to meet the regulatory changes. Electric propulsion systems have the advantage of being able to utilize various power sources, thereby enabling a grid connection of eco-friendly power sources. However, because the operating characteristics vary depending on the type of power source, the design of an energy management system suitable for the ship’s operating environment is necessary to facilitate optimum control of the energy system. Amongst the various control strategies available, state machines and rule-based controls have been employed extensively in hybrid systems. In addition, the rules have been incorporated into the neural network algorithm to enable the operation of complex systems or under unpredictable circumstances. In this study, the conventional rule-based strategy was simplified, and a neural network was trained with a revised control strategy. The operability of the hybrid system was examined through MATLAB/Simulink simulations. The findings of this study are expected to be of use as an energy management system for batteries and generators, as well as various other eco-friendly power generation systems.

Keywords:

Hybrid system, Equivalent consumption minimization strategy, Neural network, Optimum control, Rule-based strategy1. Introduction

The International Maritime Organization (IMO) has formulated more stringent regulations on the pollutants emitted by ships and set the target of reducing CO2 emissions by 50%–70% by 2050 compared to the emission levels in 2008 [1]. In South Korea, the Act on Promotion of the Development and Distribution of Environment-Friendly Ship was enforced in 2020, and the use of eco-friendly propulsion systems is mandated for new shipbuilding activities [2]. In this regard, the electric propulsion systems that facilitate the grid connection of eco-friendly power sources have emerged as a key alternative solution. The design of the energy management systems is important for the optimal energy control of the hybrid systems operated with various types of power sources, each with different properties [3]. A wide range of control strategies are employed in energy management systems not only in ships but also in other industrial sectors. Rule-based control strategies conforming to the system design have been proposed in addition to the traditional Proportional-Integral controller, state-based machines, and fuzzy controller [4][5].

To minimize the energy consumption, the equivalent consumption minimization strategy (ECMS) has been applied to rule-based control strategies [6]. In the present study, a conventional rule-based control scheme applied to generator–battery hybrid systems [7] is introduced [8], and the characteristics of the newly proposed rule-based control strategy are described. In the design of the neural networks implementing the proposed rule-based strategy, the output value of the power source is not used as the output value of the neural network; however, the operating mode reference value of the power source is set as the design value of the neural network. Neural network training was then performed under this setting, and the excellent performance of the optimal control scheme of the proposed strategy was verified for specific load conditions via MATLAB/Simulink simulations.

2. Conventional Rule-Based Strategy Based on Equivalent Consumption Minimization Strategy

2.1 Rule-based strategy

In the case of the conventional rule-based control strategy used in battery hybrid systems for ships, the system specifications are selected, and the load-sharing section criteria for the generator are set according to the number of generator units and settings of the battery, SOCMIN (minimum state of charge) and SOCMAX (maximum state of charge). Subsequently, the status of the generator is categorized into single/parallel and stop/variable/maximum loads. The generator output varies according to the load of the ship and the SOC of the battery, where the prescribed rule is composed of if–then statements and accounts for load sharing. However, if the number of rules increase, the system design becomes more complex [9], and when the optimum specific fuel oil consumption (SFOC) is not taken into account according to the load of the power source, the load sharing is performed arithmetically, leading to inefficient operation.

2.2 ECMS

To address the aforementioned limitations, a control strategy is designed in which the optimum operating point of a power source is set as the reference point for the operating mode change as well as the output reference value of the power source, referred to as the ECMS [5]. Table 1 shows an example design using this strategy [8]. Depending on the system designer, the settings of the load sharing reference point α, SOCMIN and SOCMAX of the battery, the minimum/optimum/maximum operating points of the power source differ, and the variable operating point changes in size according to the load condition.

| (1) |

where, Pload is the propulsion motor load, Gmax is the maximum output of the genset, and Pbatt is the battery power.

3. Proposed Rule-Based Strategy with a Neural Network

3.1 Conventional rule-based strategy

The conventional rule-based control strategy is based on the rule of if–then statements, with the battery SOC and load of the ship as inputs and the generator power as the output according to the given conditions. However, with an increasing number of generator units and requirements, the number of rules also increase thereby expanding the system complexity.

3.2 Proposed rule-based strategy using neural networks

A method for training a neural network by calculating the generator output reference value of the expected condition according to the rule-based control strategy was proposed [8]. However, the neural network design can be simplified using the operating mode as a reference value instead of the generator output in the neural network controller design.

As presented in Table 2, the generator operating mode can be classified into three states (1: stop; 2: variable (0%–100%); and 3: optimum (75%)). The different cases in which the two generator units are operated in each mode are defined as modes L1 to L6. As shown in Table 2, the 75% optimum operating point of the generator is set as a reference value for the operating mode section change, and the optimum operating mode is set as the reference value of the generator’s operation. The state of the battery was controlled for these conditions according to the following equation:

| (2) |

where, PGn is the output of genset number n.

3.3 Result derived from the proposed rule-based strategy for designing a neural network controller

Based on the proposed rule-based control strategy, the training data for the neural network are represented in terms of the ship load and battery SOC, as shown in Table 3. In the conventional rule-based control strategy reflecting the ECMS, the generator output reference value is used for neural network training. However, in the proposed strategy, the generator operating modes presented in Table 2 are set as the reference values in the neural network.

3.4 Training result by neural network controller

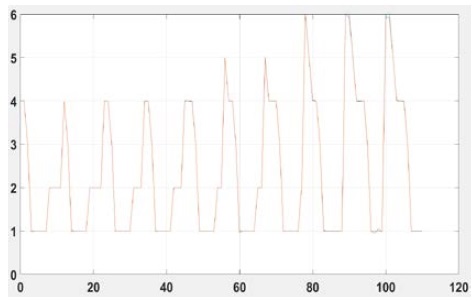

The training data shown in Table 3 were used to train the neural network, the results of which are shown in Figure 1. The results show good agreement between the predicted values and the design.

3.5 Simulation

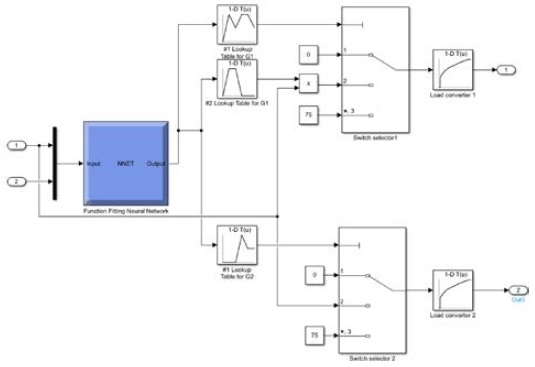

To examine the functions of the neural network controller described previously and identify the problems before use in the energy management system of a battery hybrid system under load conditions with real-time changes, MATLAB/Simulink simulations of the system were conducted, and the load sharing performance equivalent to the training data was analyzed under various load conditions. Figure 2 shows a load divider designed to apply the simplified rule-based strategy. First, the real-time incoming load of the ship and SOC of the battery are the two input values, and the neural network provides outputs as the pre-learned modes 1 to 6 as output values.

Subsequently, to provide a split command to the two generators, it is transmitted to each primary lookup table. As shown in Table 2, when the NN output is changed between modes 1 and 6, the primary lookup table transmits the generator status commands of 1,2,3 to the switch selector. If it is 1, it is stopped; if it is 2, it is a variable load, and if it is 3, it is operated in the optimal operation mode. In the case of stop and optimal operation commands, a fixed value of 0% and 75% as the designer’s decision can be input to the generators through the switch selector regardless of the load; however, it must be transmitted in real time in the case of a variable load. For this purpose, a secondary lookup table was used. Specifically, in the case of a single operation among L3, L5, and L6 requiring variable operation sections, L3 only orders a single operation, and in the case of L5 and L6, it has the function of operating G1 and G2, which are parallel sections. The final output from this is transferred to a lookup table that is converted into a value corresponding to revolutions per minute (RPM) as the output order of the variable-speed generator. Here, the switch selector transmits the operation reference value to the generator according to the scheme in Table 2, which are predetermined signals, and the switch itself is designed to operate only in the stop, variable, and optimum modes.

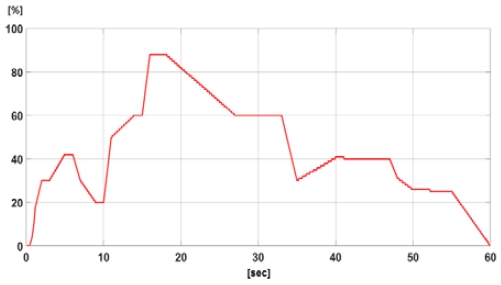

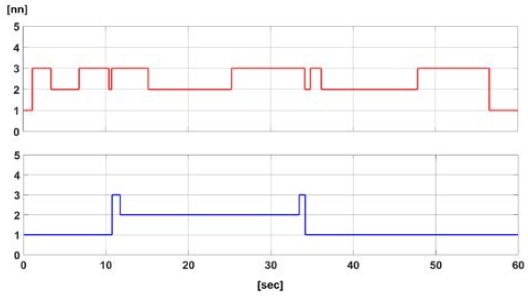

Figure 3 shows the load profile to verify that the proposed simplified rule-based strategy is applied accurately to the battery hybrid system model using a neural network controller.

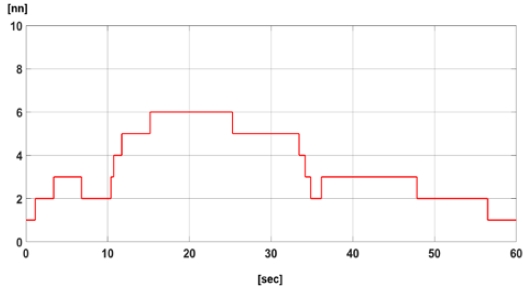

In the case of a neural network controller using the load of the ship and the SOC of the battery as input values, the neural network output values shown in Figure 4 were obtained according to the training data in Table 3. In this simulation, the SOC of the battery at the beginning was 50% and changed according to the load balancing.

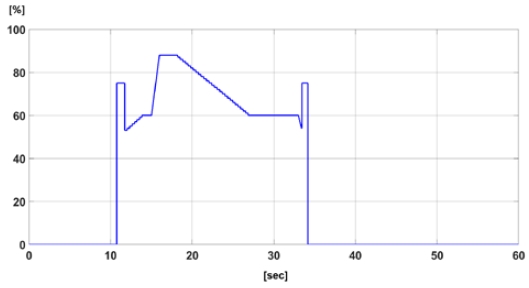

Figure 5 shows the verification of the implementation of the rules proposed in Table 2 using the switch selector in the neural network output.

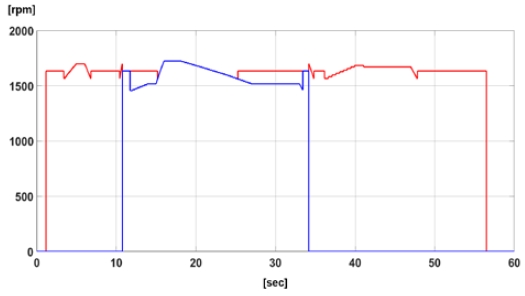

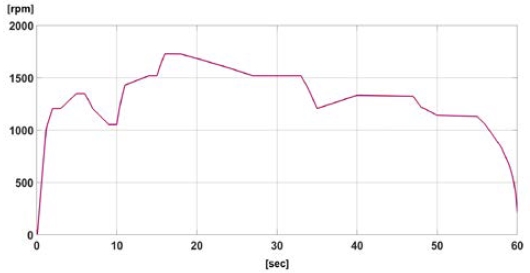

Figure 6 shows the RPMs of the variable speed generators no.1 (red line) and 2 (blue line), according to the output reference values.

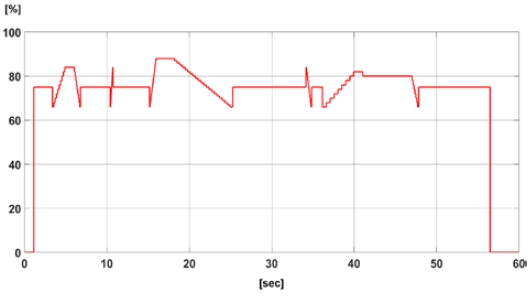

Figure 7 and 8 show the outputs of the generators reflecting the output of the switch selector.

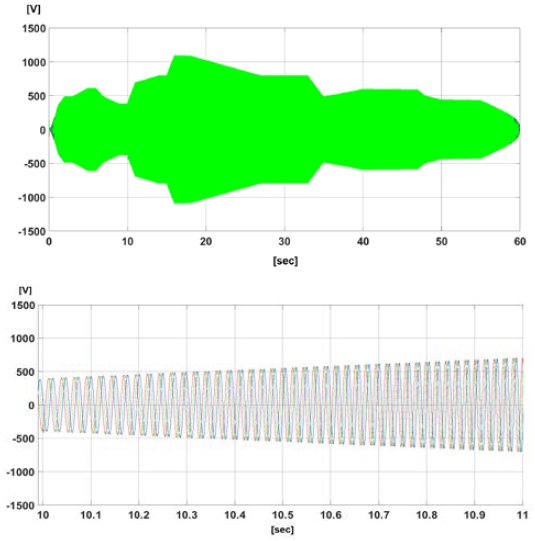

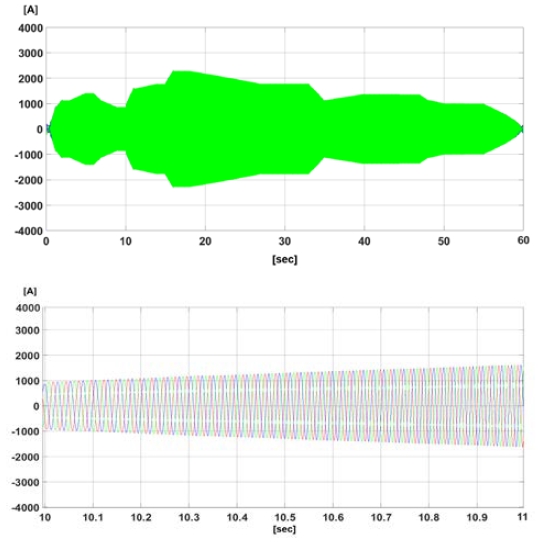

The changes in the RPM, voltage, and current of the propulsion motor according to the load are shown in Figures 9, 10, and 11, respectively. A torque load proportional to the squared value of the RPM is applied to the propulsion motor, and excellent dynamic characteristics are confirmed by the motor controller using indirect vector control.

4. Conclusion

The results of this study confirm that the proposed design conditions can be used to train a neural network with simplified rules incorporating ECMS, thereby enabling a more convenient operation compared with the conventional neural network design. The proposed strategy enables the incorporation of the optimum operating point of the power source in the design. However, the rules can be applied to varying conditions, such as, changes in the capacity or number of generator units. As observed from the simulation results using MATLAB/Simulink, excellent load sharing performance and dynamic characteristics of the propulsion motor were achieved using the neural network controller trained with the simplified rules.

Acknowledgments

This work was supported by the Technology development program(P0016077) funded by the Ministry of SMEs and Startups (MSS, Korea).

Author Contributions

Conceptualization, S. W. Kim, H. M. Jeon; Methodology, S. W. Kim; Software, S. W. Kim; Validation, S. W. Kim, H. M. Jeon, and K. K. Yoon; Formal Analysis, S. W. Kim; Investigation, S. W. Kim; Resources, S. W. Kim; Data Curation, S. W. Kim, H. M. Jeon; Writing—Original Draft Preparation, S. W. Kim; Writing—Review & Editing, K. K. Yoon; Visualization, S. W. Kim; Supervision, K. K. Yoon; Project Administration, K. K. Yoon; Funding Acquisition, K. K. Yoon.

References

-

G. -R. Park and K. -H. Cho, “A suggestion on the incentive and penalty based on carbon tax scheme through EEOI results,” Journal of the Korean Society of Marine Engineering, vol. 41, no. 4, pp. 323-329, 2017 (in Korean).

[https://doi.org/10.5916/jkosme.2017.41.4.323]

- Ministry of Oceans and Fisheries, Industry and Energy, Act on Promotion of Development and Distribution of Eco-Friendly Ships, Republic of Korea, Accessed September 28, 2021.

-

R. D. Geertsma, R. R. Negenborn, K. Visser, and J. J. Hopman, “Design and control of hybrid power and propulsion systems for smart ships: A review of developments,” Applied Energy, vol. 194, pp. 30-54, 2017.

[https://doi.org/10.1016/j.apenergy.2017.02.060]

-

S. N. Motapon, L. -A. Dessaint, and K. Al-Haddad, “A comparative study of energy management schemes for a fuel-cell hybrid emergency power system of more-electric aircraft,” IEEE transactions on industrial electronics, vol. 61, no. 3, pp. 1320-1334, 2014.

[https://doi.org/10.1109/TIE.2013.2257152]

-

L. W. Y. Chua, T. Tjahjowidodo, G. G. L. Seet, and R. Chan, “Implementation of optimization-based power management for all-electric hybrid vessels,” IEEE Access, vol. 6, pp. 74339-74354, 2018.

[https://doi.org/10.1109/ACCESS.2018.2883324]

- L. C. W. Yuan, T. Tjahjowidodo, G. S. G. Lee, R. Chan and A. K. Ådnanes, “Equivalent consumption minimization strategy for hybrid all-electric tugboats to optimize fuel savings,” 2016 American Control Conference (ACC), pp. 6803-6808, 2016.

-

J. S. Oh, and Y. M. Kang, “Energy savings in ship power systems by using batteries,” Journal of the Korean Society of Marine Engineering, vol. 41, no. 6, pp. 576-582, 2017 (in Korean).

[https://doi.org/10.5916/jkosme.2017.41.6.576]

- S. W. Kim, A Study on Optimal Energy Control of Generator-Battery Hybrid System for Ship Using Neural Network, Ph. D. Dissertation, Department of Marine System Engineering, Korea Maritime & Ocean University(KMOU), Korea, 2021(in Korean).

- T. M. N. Bui, T. Q. Dinh, J. Marco and C. Watts, “An energy management strategy for DC hybrid electric propulsion system of marine vessels,” 2018 5th International Conference on Control, Decision and Information Technologies (CoDIT), pp. 80-85, 2018.