Design of an integrated network management system for telecom subsystem in offshore plants

Copyright ⓒ The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

This study analyzed the offshore plant industry and related regulations such as ISO, IEC, and Norsok Standards to develop an integrated network management system (INMS) capable of both on-site and remote management and configuration of IP-based network equipment in offshore plants. The INMS was designed based on actual specifications and POS plans, and a plan of management was verified through an offshore plant engineering company. Various modules such as PAGA interface modules, CCTV, IP-PBX, and HF-radio communication modules were developed for system implementation. Protocol and data design and screen design were followed by framework development and introduction of the automatic satellite communication function

Keywords:

Integrated network management System, Norsok standard, IP-based network, Marine satellite communication, Telecom subsystem in offshore plant1. Introduction

Offshore plants, which are offshore structures built to produce energy from resources such as fuel and natural gas, utilize CCTV and various telecom subsystems for a wide range of applications owing to the high risks involved. In addition, they rely on marine satellite communications and submarine cables owing to their limited land accessibility [1].

Recently the supply of marine IT equipment has been accelerated by changes in the marine satellite communication market, the signing of international agreements, and enhanced social awareness. Compared to the past, there is increasing emphasis on automation systems and network equipment, and this has highlighted the need for efficient equipment management technologies [2][3].

Against this backdrop, this study proposes an integrated network management system (INMS) capable of both on-site and remote management and configuration of IP-based network equipment in offshore plants. This paper is organized as follows. Section 2 analyzes the requirements of the INMS (Integrated network management system) for offshore plants. Sections 3 and 4 describe the design of the integrated network management system. Section 5 examines unit system development, and Section 6 provides the conclusion.

2. Requirements analysis for integrated networkmanagement systems in offshore plants

While IT equipment and wireless network technology account for 7 to 8% of ship prices, this figure is expected to increase to 15% by 2018. IT equipment expenses, which comprise 20% of the cost of offshore plants, are also likely to increase [4][5]. In such applications, IP-based wired and wireless communications are used together, and various types of IP-based equipment are installed. Despite the sophistication of marine communication systems, however, IP-based equipment and networks are being managed by general crews instead of network professionals. Service engineers must be hired separately when there are network problems or troubleshooting delays, resulting in poorer efficiency and higher management costs [2].

To resolve the aforementioned issues through advanced marine IT and products with good market competitiveness, this study determined the requirements of the INMS based on an analysis of leading products and related policies.

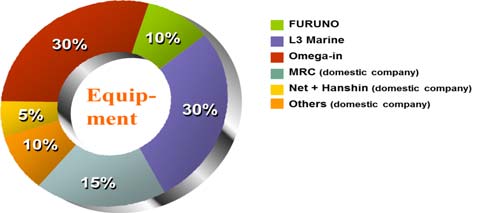

2.1 Domestic and foreign markets in offshore plant communication

The demand for marine wireless/wired integrated technology and Voice over Internet Protocol (VoIP) products has rapidly increased with the transition of the marine satellite communication market from Inmarsat to MVSAT, the signing of international agreements, and enhanced social awareness. As shown in Figure 1, the marine satellite communication market is mostly composed of foreign companies, while domestic companies are limited to agents, AS, and installation support. Although 75% of offshore plants undergo drying in Korea, domestic companies including MRC, Net, and Han-shin Electronics account for only 30% of the marine plant network equipment market. Given that the key products are analog equipment, domestic companies are facing a decrease in their market shares. This reinforces the importance of acquiring IP-based network equipment technology.

2.2 Development of leading product

With the diversification and sophistication of communication equipment in offshore plants, new communication devices often have integrated functions to reduce costs and facilitate maintenance. Given the recent advances in communications and the increased proportion of IT equipment on ships, it is necessary to utilize products that offer integrated network management and remote maintenance.

The All-In System by Omega Integration and the Marine System by L-3 M&PS can not only fulfill user requirements according to the sizes and purposes of the ships and offshore plants, but can also provide solutions for easier management. As shown in Figure 2, the two systems represent 60% of the entire market.

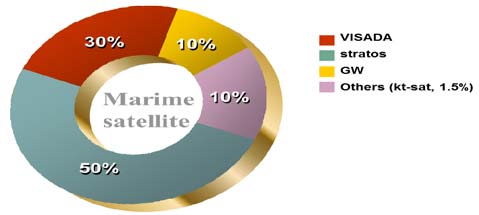

While Omega Integration and L-3 M&PS are more focused on network equipment, Kongsberg, a leading company in marine automation, supports the efficient maintenance of offshore plants and ships by managing types of various onboard equipment through a bridge system known as K-INMS (Kongsberg Information Management System). JRC, a leading company in marine communications, developed a remote maintenance system (RMS) to offer remote maintenance for their products. This is shown in Figure 3.

2.3 Related regulations

The offshore plant industry has shown a heightened interest in safety equipment following the recent oil spill in the Gulf of Mexico. Major brands have enforced related regulations, and latecomers are facing higher market barriers [6].

Basic regulations for offshore plants are shown in Table 1. IEC 61508 is the international standard for the functional safety of electrical and electronic elements [7]. Norsok standards related to telecom systems in offshore plants can be found in Table 2[8]-[10].

2.4 Requirements of integrated network system for offshore plants

Because offshore plants pose various risks to workers, all equipment must be highly reliable and able to recover rapidly from failure, as stated in Section 2.2. In particular, fixed offshore plants must support remote maintenance, as they have very limited access to land. As noted in Section 2.1, analog communication systems are being transformed into IP-based systems, and many problems, such as inexperienced operations and delayed recovery, have resulted from the lack of professionals. User-centered solutions must be developed to allow easier access for crewmen and to minimize losses from human error. Given the trend of integrated telecommunications in offshore plants and the enforcement of international regulations, new systems must comply with the IEEE standard and the Norsok standards.

To address the development of integrated network solutions offering on-site and remote management and the configuration of IP-based network equipment in offshore plants, the following requirements were derived:

- 1. Equipment configuration and system monitoring

- : Supports the configuration and pre-testing of IP-based communications equipment and marine apparatuses; provides monitoring and control for network equipment, CCTV, PAGA, and analog equipment

- 2. Efficient user-centered management support

- : Implementation of user-centered functions to improve accessibility for workers lacking professional knowledge

- 3. Remote management of coastal offshore plants

- : Remote CCTV monitoring via submarine optical cables installed in offshore plants, and remote management of work sites using PAGA

- 4. Integrated system offering the on-site and remote management of offshore plants

- : Alarm warnings for failure using IP-based satellite communication networks (FBB, VSAT, GX, emd); development of remote control system capable of quick recovery

- 5. Fulfillment of IEEE 802, IEEE 802.3, IEEE802.11af, and Norsok T-100 standards

3. Functional Design of the INMS

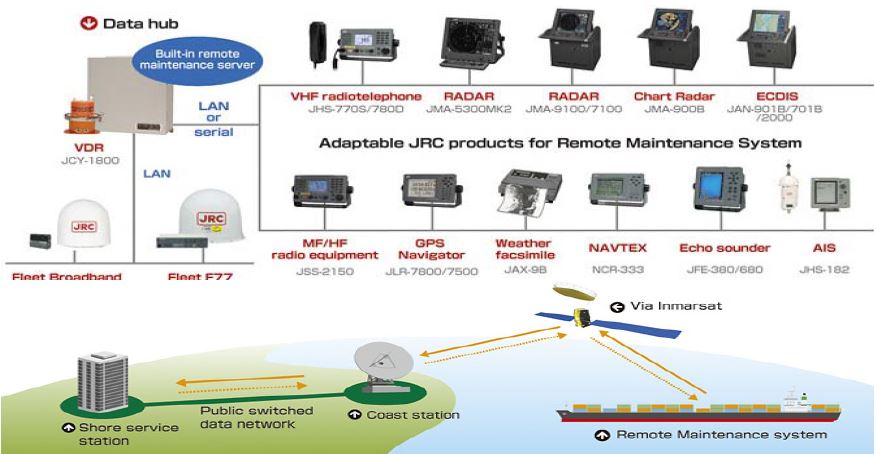

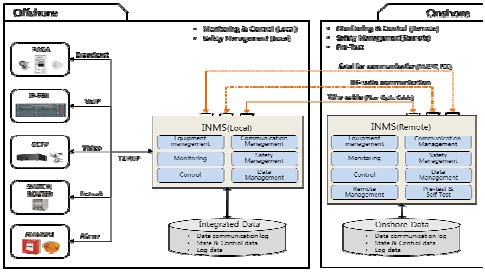

To develop a system that allows for the configuration, monitoring and operation of IP-based telecom subsystems from onshore the components of the INMS were derived, as shown in Figure 4 and Table 3.

3.1 Network management

Since there are many analog and digital devices inside offshore plants such as switches, APs, exchangers, PAGAs, CCTVs, and clocks, interface modules that can digitalize analog communication devices and control each device were developed to enable IP-based control. Furthermore, the system was designed to allow for configuration, operation, and fault recovery though a unified processor.

3.2 Internal and remote work management

As there are many dangerous areas which are difficult to access in an offshore telecom subsystem, CCTVs, PA, GA were interconnected to support the management of the offshore plant. Furthermore, submarine fiber-optic cables installed on a fixed platform and a high-speed IP maritime satellite network are used to manage the internal work environments of offshore plants from onshore.

3.3 Operation support from the user’s perspective

It is practically impossible for people who have no background knowledge or experience with networks to operate an L3 switch, which is a basic component of the IP networks inside offshore plants. However, IT and/or network specialists do not exist in offshore plants. Therefore, the system was configured to allow for the easy setup and monitoring of a telecom subsystem using an operation program developed in accordance with the process. Furthermore, the equipment configuration and pre-test features were implemented to support the installation and test operation of the equipment.

4. Design of the INMS

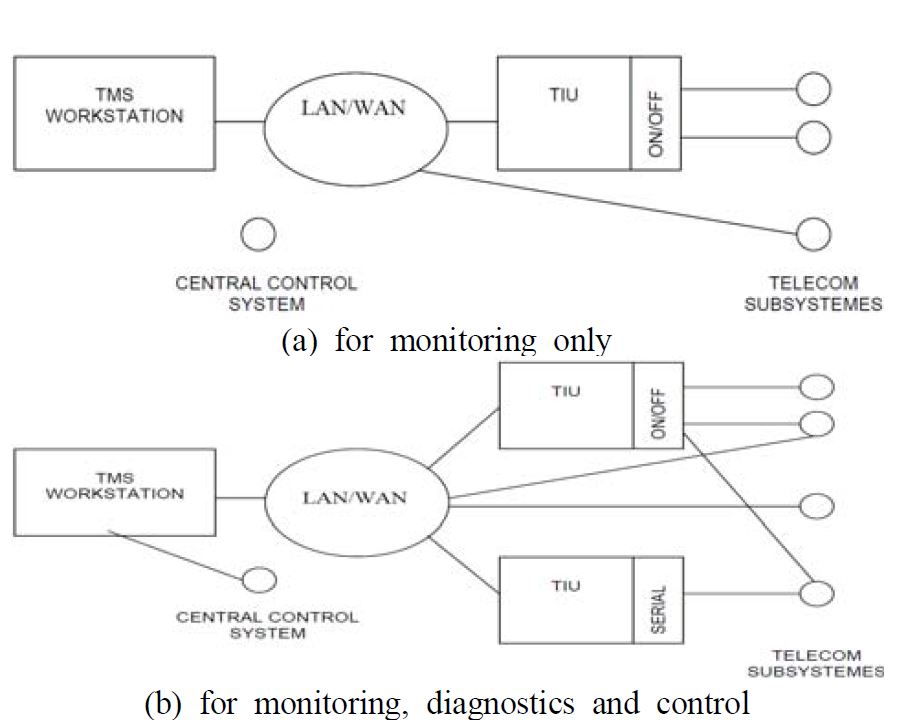

According to Norsok standard T-100, the purpose of a telecommunication monitoring system (TMS) is the remote monitoring of telecom subsystems on offshore production installations. The system shall have an alarm interface for the transmission of alarms to a central control system. The configuration is shown in Figure 5 (a).

The remote diagnostic and control function is an optional function. If this function is included in the TMS, the system should be configured as shown in Figure 5 (b). The diagnostic software that is normally supplied together with the telecom subsystem should then be used.

TMS communication protocols and the physical interfaces for the telecom subsystems should be adapted to a common standard in order to permit standardized communication to a workstation [10].

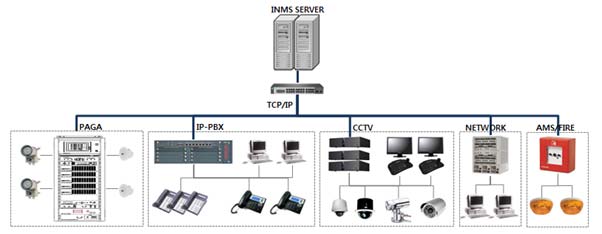

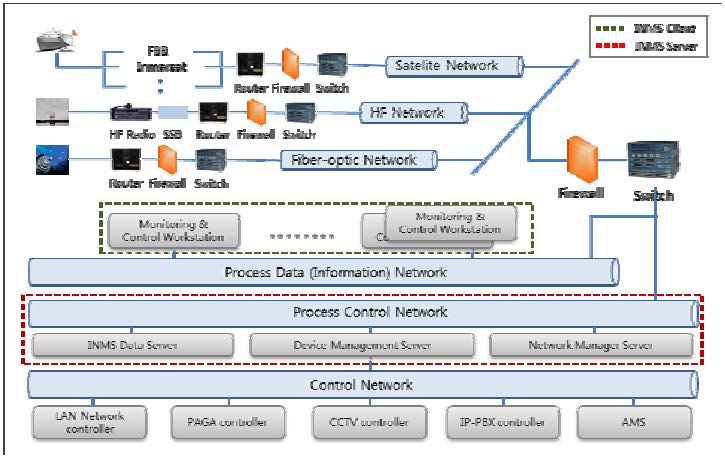

The INMS was designed as shown in Figures 6 - 8, satisfying the conditions of Norsok standard T-100, the technical specifications of ship management companies, and a shipyard POS. The INMS proposed in this study not only supports the monitoring and remote maintenance of telecommunication systems in offshore plants but also provides on-site and remote control of offshore plants. The system, which includes an INMS server, onboard network equipment, and IP-PBX, PAGA, and CCTV components, was configured as shown in Figures 6 and 7 to respond efficiently in cases of emergency. The network structure was designed as shown in Figure 8 to synchronize the data based on satellite communications and optical submarine cable communications involving Inmarsat, VSAT, and FBB, to facilitate real-time operations, and to enable the configuration, monitoring, and control of network equipment in offshore plants. The INMS network structure permits access to external networks such as satellite communication networks, HF-radio communication networks, and fiber-optic communication networks, as well as internal networks such as the data network and the control network for enhanced system security.

The adapter/drive method was applied to the INMS and the physical interfaces to telecom subsystems such as the network equipment and PAGA, IP-PBX, and CCTV components, enabling flexible adaptation to changes in network management protocols and equipment specifications. In accordance with relevant regulations, TCP/IP was applied to the INMS communication protocols.

The feasibility of the INMS was verified based on the conceptual design and the interface, protocol, and database of the operating program, as well as the management plan.

5. Development of the INMS Unit system

5.1 Development Environment

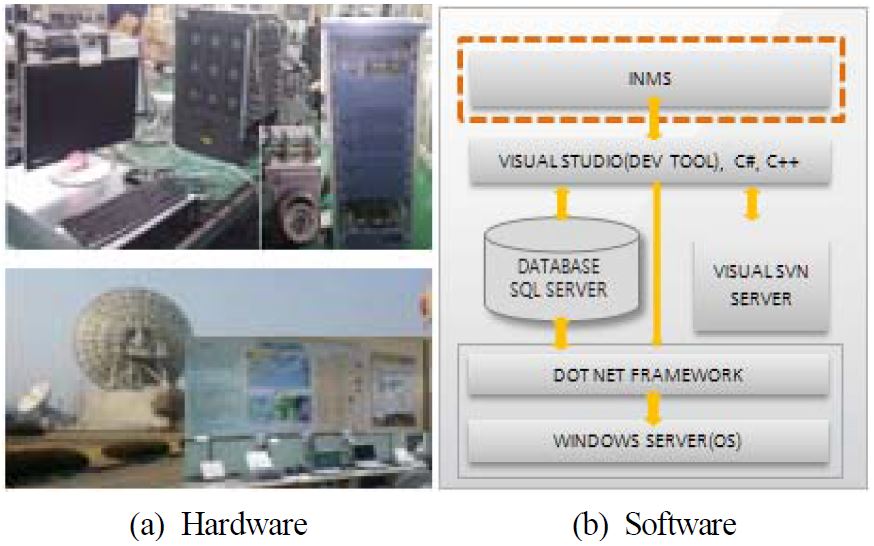

The specifications of the system used in this study, as shown in Figure 9, are identical to those of a fixed platform equipped with submarine optical cables and satellite communications. The program development environment, presented in Figure 10, is the MS.NET framework.

5.2 GUI design by function

The main screen of the INMS was designed as shown in Figure 8 to enable the configuration of IP-based network equipment, status monitoring, equipment operation, and remote control of offshore plants.

Given that the equipment configuration and status monitoring are not used constantly, detailed functions become accessible depending on input by the user. Users are able to monitor and control common equipment such as the PAGA, IP-PBX, and CCTV equipment, while also having access to navigation data and alarm messages.

5.3 Development of the PAGA interface module

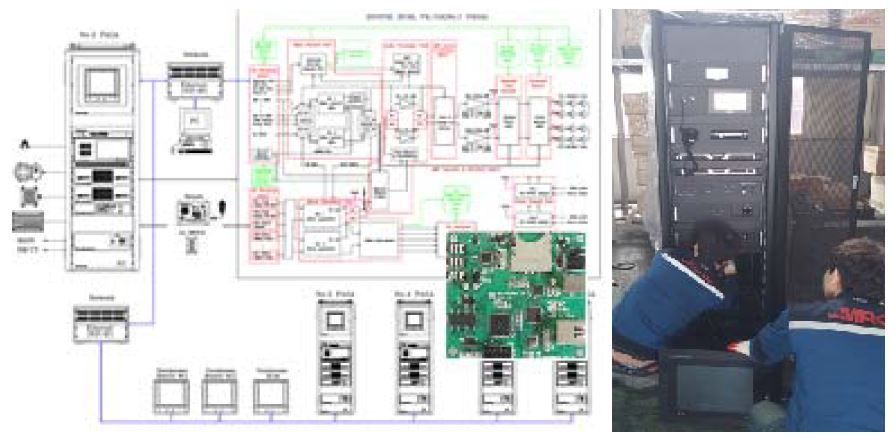

In accordance with ship-owner requirements, offshore plants consist mostly of IP-based network equipment. As presented in Figure 11, the digital conversion of sound sources from an analog public address (PA) system was required for synchronization with INMS, and a PAGA interface module was developed for integrated management with the GA equipment. Performance tests were carried out as shown in Figure 11.

5.4 Development the of program framework

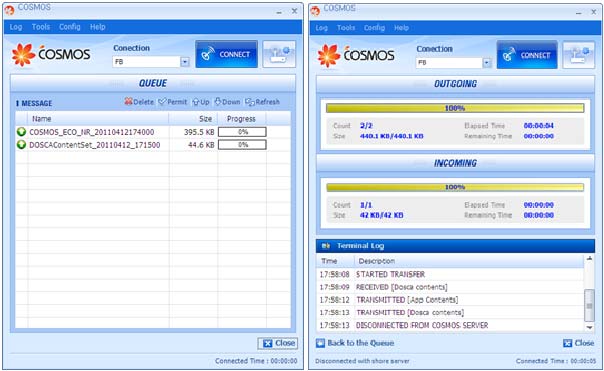

As presented in Figure 12, the basic framework of the INMS program is the server library on land, the client library of the offshore plant, and a common library. From a technical perspective, its components are the communication service, server gateway application, and client gateway application. In particular, TCP and ZIP compression modules are not used in the INMS framework. It is optimized for a satellite communication environment by integrating a data transmission function with high-efficiency compression.

5.5 Development of an auto-connection function for satellite communication

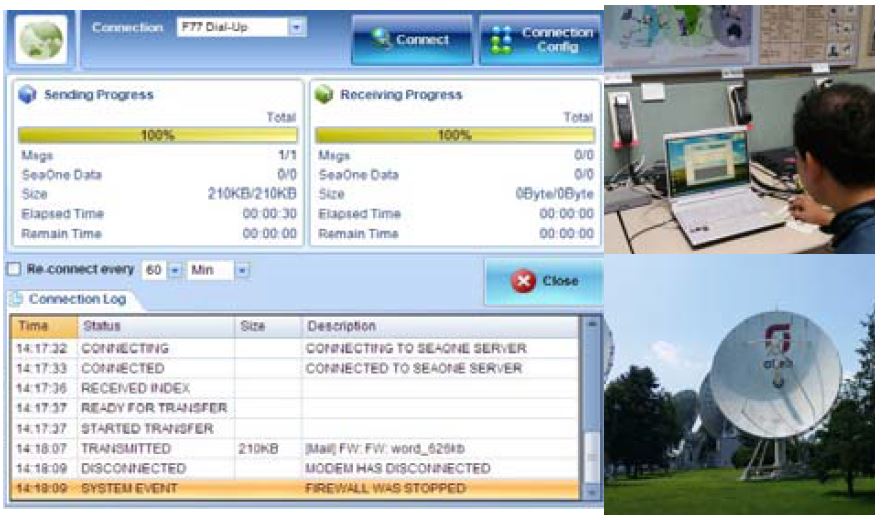

For the on-site and remote operation of INMS in real time, communication between offshore plants and land is essential. Synchronized communication is necessary to synchronize data. As shown in Figures 9 and 10, an auto-connection management function was introduced to enable session connections without a separate connection application, and a connection scheduler was employed to set up satellite session connections according to a schedule. A function test was performed at the KTsat Geumsan Satellite Communications Station as shown in Figure 13.

6. Conclusion

This study designed an integrated network management system (INMS) and developed a unit module function to enable on-site and remote IP-based integrated network management. A summary is given below:

- 1) Technical specifications and related regulations were analyzed with regard to the IT drive requirements for the design of the INMS. The system configuration, network structure, and system design plans were verified by an offshore plant engineering company.

- 2) For the development of the INMS, the study established communication protocols, designed a database and interface module, set up a development environment using the MS.NET framework, and implemented a development environment with the same specifications used in fixed-type offshore plants.

- 3) The INMS framework, serving as the unit module of the INMS, automatic connection to satellite communications, CCTV, PAGA interface module, and an HF-radio communication module were developed and tested to assess their performance.

Future work will involve module development, system integration, and an evaluation of the quality of the INMS through tests on actual ships.

Acknowledgments

This study was supported by a grant under the Innopolis Technology Commercialization Project (2014BS005) of the Ministry of Science, ICT and Future Planning.

References

-

H. K. kim, H. G. Hwang, G. J. Yoo, J. S. Lee, H. C. Park, O. K. Shin, and S. D. Lee, “A development of video-complex remote monitoring system for offshore plant”, Journal of the Korean Society of Marine Engineering, 38(1), p56-63, (2014).

[https://doi.org/10.5916/jkosme.2014.38.1.56]

- H. S. Keon, J. H. Park, J. K. Yang, and J. K. Lee, “Development of remote maintenance system for onboard IP-based equipment”, Journal of Ship and Ocean Technology, 51(1), p31-39, (2014).

- M. A. Jung, S. R. Lee, and Y. W. Lee, “Present condition and outlook for IT shipbuilding technology”, Journal of Communication and Networks, 30(10), p38-45, (2013).

- K. S. Han, S. C. Han, and J. H. Park, “IT convergence in shipbuilding and offshore plant”, Transaction of the KSME A, 53(11), p48-53, (2013).

- Shipbuilding & Offshore plant industry Technology development trends and analysis of strategy for marine equipment industry, Knowledge Industry Information Institute, (2014, November).

-

J. S. Oh, G. S. Kim, and J. H. Jang, “A study on entry into the offshore service market through slack model”, Journal of Navigation and Port Research, 38(2), p163-170, (2014).

[https://doi.org/10.5394/KINPR.2014.38.2.163]

- R&D strategy for new and leading industries (2012-2016), Korea Evaluation Institute of Industrial Technology, (2014, November).

- Norsok Standard T-001, “Telecom systems”, Revision. 4, (2010).

- Norsok Standard T-003, “Telecommunication and It System For Drilling Units”, Revision. 3, (2010).

- Norsok Standard T-100, “Telecom subsystems”, Revision. 4, (2010).