MASS engine room FMEA using evidential reasoning method

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Failure mode and effects analysis (FMEA) has been widely applied across various industries because of its ability to identify potential risk factors and calculate the risk priority number (RPN) by ranking risks. Maritime autonomous surface ships (MASS) have emerged as a core component of the Fourth Industrial Revolution in the shipping industry. Consequently, studies have been conducted to apply the FMEA to risk assessment in MASS. However, most studies have focused on the ship itself from a macroscopic perspective, with little research on the risk analysis of engine room operations in an unmanned environment. Therefore, in this study, an FMEA was conducted on a freshwater generator system in the engine room of a stage-2 autonomous ship with input from three experts. In addition, the evidential reasoning technique was introduced to address the limitations of the traditional RPN calculation, which can be subjectively influenced by the evaluator’s expertise and background. This approach demonstrates that subjective and qualitative RPN calculations can be transformed into more comprehensive and quantitative results. Using this methodology, the study identified ejector pump malfunction as the highest-risk failure mode among the five potential hazards suggested by experts in the system.

Keywords:

Autonomous surface ship, Engine-room, Failure mode effect analysis, Evidential reasoning, Risk priority number1. Introduction

As the autonomous driving technology for transportation continues to advance, there is a growing need for risk analysis tools to evaluate the safety and reliability of systems that incorporate these new technologies. Failure mode and effects analysis (FMEA) is an engineering technique used to define, identify, and eliminate failure modes in systems, designs, processes, and services before predictable or potential failures, problems, or errors affect users. The ultimate objective of this technique is to determine the risk priority among multiple failure modes by assigning a score to the risk of each identified failure mode and ensuring that appropriate follow-up actions are performed based on the priority [1]. This risk priority is called the risk priority number (RPN), and its value is obtained by multiplying three elements: occurrence (O), severity (S), and detection (D) of failure, as shown in Equation (1).

| (1) |

The values of the three elements O, S, and D generally range from 1 to 5 (referred to as scores or ratings), although this range can be extended from 1 to 10 depending on the judgment of the group conducting the risk assessment. Owing to its advantages in evaluating risks and assigning priorities through calculation formulas, the FMEA has been applied in various fields and industries. It encompasses various stages of industrial development, including design, production, and operation.

The International Maritime Organization specifically named the autonomous ship the “maritime autonomous surface ship” (MASS), and various scientific technologies mobilized during the development process have become central to the Fourth Industrial Revolution in shipping. Autonomous ships plan and execute operational tasks using automatic systems, and provide operational control and decision-making support based on big data. This is expected to reduce the workload of crew members and managers, and eliminate human error factors.

The engine room of a ship houses the main engine and auxiliary machinery that generates propulsive power. As the environment transitions from a manned to an unmanned automated system, new risk factors are expected to emerge. Therefore, studies that systematically identify and evaluate the potential risks in the engine room are crucial for ensuring the safe operation of autonomous ships. In response, previous studies have applied the FMEA to MASS for the risk assessment of unmanned ship operating systems [2]-[4].

However, most previous studies conducted risk assessments only between risk factors corresponding to higher-level concepts from a macroscopic perspective. For example, Ahmet Lutfi Tuncel [5] primarily focused on evaluating the potential risks related to human error, interaction with manned ships, interaction with the physical environment, cyberattacks, and equipment failure. Considering that the development of autonomous ships began in Europe in 2012 and has continued for over 10 years [6], numerous studies have indicated that academic efforts in this area have primarily concentrated on navigation [7]-[10]. For instance, studies have been conducted on applying artificial intelligence technology to navigation to improve route prediction and autonomous navigation capabilities, as well as on effective unmanned operation plans with ports. Legal issues regarding autonomous ships in the event of an accident have also been discussed [11][12]. However, studies related to the engine room systems of autonomous ships have been limited to the development of device-monitoring technologies [13][14]. In autonomous ships, data currently checked onsite by crew members are monitored and used as control data according to the unmanned environment and operational purposes.

Considering these changes, there is a need for an evaluation method for systems with several potential risks and uncertainties in the engine room and for an opinion collection algorithm that can objectively gather the individual risk assessment of autonomous ships from experts with diverse experiences.

2. Methodology

2.1 FMEA Linguistic Scale and Limitations

The FMEA has proven to be one of the most important early preventative initiatives in the system design, production, and service phases. The analysis method involves determining the scale of risk factors (O, S, D) by considering the linguistic scale and definitions in Tables 1 and 2, and then applying it to Equation (1).

Despite its advantage of being able to evaluate risk by prioritizing failure modes based on calculation results, the FMEA has the following limitations [1]:

- • It relies heavily on expert judgment, making its evaluation subjective.

- • It relies mainly on qualitative evaluation, often resulting in a lack of quantitative data.

- • The RPN is calculated by simple multiplication; therefore, if even one low-scoring element is included, the overall score may decrease. This may result in less consistency with the actual risks.

To overcome these limitations, this study applies the evidential reasoning (ER) technique to an FMEA evaluation formula. This approach aims to mitigate the subjectivity of qualitative evaluations and enhance the objectivity and precision of the RPN calculation results, which can be simplified by multiplication [1][4][15].

2.2 Evidential Reasoning Method

The ER method is a multiattribute decision-making method developed to solve complex decision-making problems. This technique integrates multiple expert opinions to address decision-making challenges. It quantitatively handles the uncertainty and ambiguity of individual opinions, enabling more accurate decision-making.

The first step in the ER technique is to calculate the degree of belief by assigning weights to experts based on their career and experience.

Assuming that the expert evaluation process is performed by experts ei (i=1, 2, ⋯, L), where L is the total number of experts, the expert group contributing to this study can be defined as E={e1, e2, ⋯, ei, ⋯,eL}. At this point, the relative weight between experts is expressed as w={w1, w2, ⋯, wi, ⋯, wL}, where wi represents the weight of the ith expert. In addition, wi has a value between 0 and 1, and the sum of the weights of all the experts is defined as 1.

The evaluation levels N considered by the experts are specified as H={H1, H2, ⋯, Hn, ⋯, HN}. βn,i refers to the ith expert’s evaluation of the variable n and represents the expert’s degree of belief. Additionally, βn,i ≥ 0 and . βn refers to the degree of belief in the variable Hn, and it is possible to combine the belief levels of several experts using an ER algorithm through Equations (2)-(3) below.

| (2) |

| (3) |

In Equation (2), the ith expert’s belief regarding the variable n is multiplied by the expert’s importance, resulting in mn,i, which is the basic probability mass. Accordingly, mn,i refers to the basic probability mass obtained by the expert for the variable Hn, and mH,i represents the probability mass not assigned to any parameter variable by the ith expert.

| (4) |

| (5) |

| (6) |

Here, mn,I(i+1) represents the aggregated basic probability that combines the basic probability masses of the 1st to (i+1)th experts. The combined process was calculated using Equations (4)-(6). Here, KI(i+1) is a normalization coefficient to normalize the combined probability mass of the experts, and βn represents the degree of belief in which all the experts’ opinions are finally aggregated.

In this study, the expert group consisted of three people who had been working on autonomous ship projects for more than three years and were able to conduct risk assessments based on their work experience and majors. Accordingly, the total number of experts was L=3, and the group was defined as E={e1, e2, e3}. The relative weights between the experts were set at W={w1=0.5, w2=0.3, w3=0.2}, with boarding experience as a significant factor in determining the weight. The variable N refers to the number of evaluation grades in this study. As there are five evaluation levels for O, S, and D, N is defined as 5, and βn,i represents the ith expert’s degree of belief regarding the variable n.

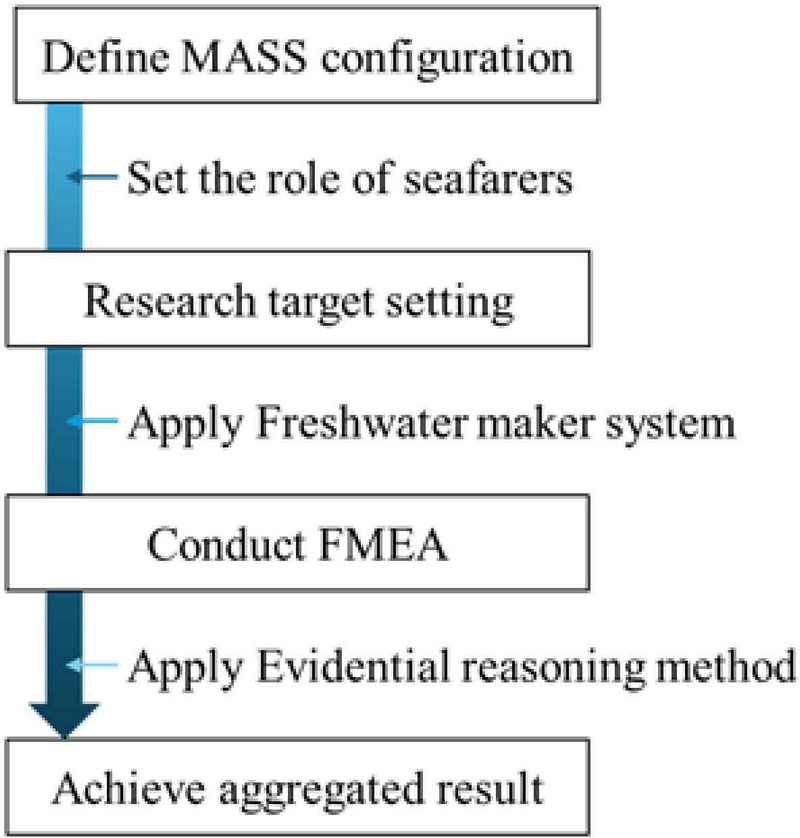

The research method used in this study, which combines the methodologies described above, is illustrated in Figure 1.

3. Research consideration

3.1 Setting Environmental Conditions for MASS Engine Room Operation

The technological development stages of autonomous ships and the expected ship operating environments are as follows.

Stage 1: Partially autonomous operation, supporting crew member decision-making

Stage 2: Minimum number of people on board, remote control possible from shore

Stage 3: Unmanned environment, remote control possible from shore

Stage 4: Fully unmanned autonomous navigation

This study considers the second stage, characterized by a minimum number of crew members on board and a remote-controllable environment from the shore. Accordingly, it was assumed that the scope of work for the crew was limited to maintenance as requested by the MASS controller from the shore.

3.2 Selection of Research Target System

The FMEA target system used in this study is a freshwater generator. The reasons for selecting this auxiliary system over the main engine are as follows:

First, the market is shifting toward installing internal combustion engines that use eco-friendly fuels owing to carbon emission regulations. Consequently, the criteria for selecting the main engines are expected to vary significantly depending on the type of ship, route, and cargo. As the supportive subsystem configuration for the main engines differs depending on the type of fuel used, the main engine was excluded from the study.

Second, the auxiliary system provides a clear representation of the current and future system changes. With a minimized number of crew members on board, it is anticipated that it will be easier to identify which equipment in the auxiliary systems is less critical. In the future, several parameters that are currently monitored manually by engineers will be processed as digital data for remote monitoring and control from the shore. Therefore, an auxiliary system that facilitates a comparison between the current and future states was chosen as the research target.

For example, a drinking water tank can be designed based on the number of crew members, which can be minimized or eliminated as autonomous-ship technology progresses to the second stage. Salinity is a critical criterion for freshwater production through seawater distillation. While salinity has been monitored as data in the past, it will become an essential control parameter for operating the freshwater system in the future. This is because the freshwater produced serves as the cooling water for the main engine and generator. If salinity is not properly controlled, it could lead to risks, such as the corrosion of cooling system pipes. Therefore, it is expected that, in addition to salinity, a significant amount of data will be monitored for the operation of the freshwater generator system, as shown in Table 3.

4. Results

4.1 FMEA Result

Considering the research conditions outlined in Sections 3.1 and 3.2, the expected FMEA results for the freshwater generator system are listed in Table 4. Maintaining the appropriate salinity of the freshwater produced by the system is anticipated to be a critical parameter in its operation. Given the limited number of personnel available to perform immediate maintenance in the engine room, it is advisable to prioritize the five failure modes based on their risks, and then determine the appropriate response measures.

4.2 ER Application and Aggregated Results

The three experts described earlier evaluated the risks listed in Table 4 based on their work experience and knowledge. They assessed the occurrence probability of each failure mode, the severity of the influence of each failure mode on the operation of the engine room system, and the probability of failure detection.

Each expert provided a degree of belief in five risk parameters. Table 5 presents the aggregated risk results based on the experts’ opinions, calculated using Equations (2)-(6):

Using the ER technique, a more objective RPN calculation result could be derived compared with the existing method in Equation (1). This was achieved by considering the weights and resolving the conflicts of opinion among the experts. For example, when evaluating FM1, one expert provided their belief regarding the probability of failure to detect a fault as HU=10%, U=20%, and A=50%, with 20% remaining uncertainty. This subjectivity was addressed by correcting the uncertainty using Equation (3) and normalizing the degree of belief of each expert using Equation (5).

The final RPN results for each failure mode, obtained using the weighted-sum method by assigning weights from 1 to 5 in order of increasing risk to the five risk parameters and applying them to Table 5, are listed in Table 6. The results confirmed that the most dangerous failure mode in Table 4 was FM3 (ejector pump malfunction), whereas the F.W. tank level was given rank 5, representing the lowest risk among the five risks.

The advantages of applying the ER method to the FMEA are as follows:

The traditional RPN calculation in the FMEA is obtained by multiplying the evaluation grades from 1 to 5. This approach results in a simple calculation; if one low-scoring element is included, the overall score is significantly lowered. This simplicity makes it challenging to overcome the subjectivity of the experts performing RPN and the limitations of qualitative evaluation, thus complicating the determination of the actual risk and the consistency of RPN results.

By applying the ER technique, a more detailed RPN calculation was possible. The ER method assigns an expert’s degree of belief to each evaluation grade, enabling a more nuanced assessment. By incorporating weights for each evaluator and quantitatively handling the uncertainty of subjective opinions, this study could derive a final judgment that simultaneously integrated both quantitative and qualitative information from the FMEA.

5. Conclusion

To prepare for the coming era of unmanned ships, this study combines the FMEA and ER methods to evaluate the risks associated with the MASS engine room, which involves numerous uncertainties and development possibilities. Assuming the second stage of autonomous-ship development as the research context, this study analyzed the failure modes that could occur in a freshwater generator system and conducted an FMEA to evaluate the risk priorities. The ER method was introduced to address the subjectivity of the qualitative evaluation and enhance the precision of the assessment.

Three experts used their experience and knowledge to assess the risks listed in Table 4, including the probability of occurrence of each failure mode, the severity of its influence on the system operation, and the likelihood of failure to detect the failure mode. The ER method, utilizing Equations (2)-(6), was employed to aggregate the experts’ opinions. By quantifying the uncertainty remaining in the risk assessment using these equations, we could objectively consolidate the experts’ evaluations. Table 6 presents the RPN rankings and calculated risks. The analysis confirmed that the most dangerous failure mode for the freshwater generator system was FM3, which was an ejector pump malfunction.

The significance of this study is as follows:

• By identifying the potential failure modes in the freshwater generator systems of autonomous ships and systematically evaluating their risks, this study clarified the prioritization of follow-up measures.

• The application of the ER methodology to the traditional FMEA demonstrated that it is possible to overcome the limitations of conventional FMEA methods, achieving a more precise and quantitative risk assessment by incorporating the objectivity of quantitative calculations into qualitative expert evaluations.

• This study provides specific FMEA application cases for the engine room systems of autonomous ships, and offers foundational data to ensure the stability of MASS in the future.

Future studies should focus on conducting risk assessments that target the main engine. Unlike auxiliary equipment, the main engine operates in conjunction with various utility systems, such as heating, cooling, and lubrication systems. Consequently, the potential risks and complexity in an unmanned environment are expected to be more diverse and intricate than the cases discussed in this paper. In this context, further studies should explore methods for enhancing the safety of engine rooms in autonomous ships through additional risk assessments of various engine systems.

The research method and case study presented herein are expected to serve as foundational data for improving the safety and efficient operation of autonomous ships by providing a more objective and quantitative evaluation of engine room risks. This study is also anticipated to be a crucial preliminary step that can be utilized in various aspects, such as design improvement, the establishment of safe operation strategies, the optimization of maintenance plans, regulatory compliance, the development of educational programs, and setting future research and development directions.

Acknowledgments

This research is supported by the 'Development of Autonomous Ship Technology(20200615)' funded by the Ministry of Oceans and Fisheries(MOF, Korea).

Author Contributions

Conceptualization, H. J. Choi and K. H. Seo; Methodology, H. J. Choi; Validation, H. J. Choi and K. H. Seo; Investigation, H. J. Choi; Resources, Formal Analysis and Data Curation, H. J. Choi and K. H. Seo; Writing—Original Draft Preparation, H. J. Choi; Writing—Review & Editing, K. H. Seo and J. U. Lee; Visualization, K. H. Seo; Supervision, J. U. Lee; Project Administration, J. U. Lee; Funding Acquisition, J. W. Lee and J. U. Lee.

References

-

K. S. Chin, Y. M. Wang, G. K. K. Poon, and J. B. Yang, “Failure mode and effects analysis using a group-based evidential reasoning approach,” Computers & Operations Research, vol. 36, no. 6, pp. 1768-1779, 2009.

[https://doi.org/10.1016/j.cor.2008.05.002]

-

P. Li, Y. Wang, and Z, Yang, “Risk assessment of maritime autonomous surface ships collisions using an FTA-FBN model,” Ocean Engineering, vol. 309, 118444, 2024.

[https://doi.org/10.1016/j.oceaneng.2024.118444]

-

W. Zhang, Y. Zhang, and C. Zhang, “Research on risk assessment of maritime autonomous surface ships based on catastrophe theory,” Reliability Engineering & System Safety, vol. 244, 109946, 2024.

[https://doi.org/10.1016/j.ress.2024.109946]

-

C. H. Chang, C. Kontovas, Q. Yu and Z. Yang, “Risk assessment of the operations of maritime autonomous surface ships,” Reliability Engineering & System Safety, vol. 207, 107324, 2021.

[https://doi.org/10.1016/j.ress.2020.107324]

-

A. L. Tunçel, S. I. Sezer, G. Elidolu, E. Uflaz, E. Akyuz, and O. Arslan, “A rule-based Bayesian network modelling under evidential reasoning theory for risk analysis of anchoring operation in maritime transportation,” Ocean Engineering, vol. 292, 116521, 2024.

[https://doi.org/10.1016/j.oceaneng.2023.116521]

- J. Kim, and H. S. Jang, “Autonomous ship technology trends and preparation”, Bulletin of the Society of Naval Architects of Korea, vol. 56, no. 4, pp. 4-7, 2019.

- W. J. Choi and S. -H. Jun, “Development of sailing algorithm for ship group navigation system,” Journal of Navigation and Port Research, vol. 46, no. 6, pp. 554-561, 2022 (in Korean).

- D. W. Kim, M. K. Lee, S. W. Park, and Y. -S. Park, “Study on changes in vessel traffic services due to introduction of maritime autonomous surface ships,” Journal of Navigation and Port Research, vol. 47, no. 6, 430-436, 2023 (in Korean).

- M. -W. Jeong and I. -S. Sin, “Development of route information exchange system for autonomous navigation support service of MASS,” Korea Institute of Information and Communication Engineering, vol. 27, no. 2, pp. 565-568, 2023. (in Korean)

- S. -T. Cha and Y. Jeong, “Development of route following algorithm for application in collision avoidance routes of maritime autonomous surface ship,” Journal of Navigation and Port Research, vol. 47, no. 6, pp. 386-393, 2023 (in Korean).

-

S. I. Lee, J. H. Choi, and Y. J. Ho, “Normative issues of Maritime Autonomous Surface Ships(MASS) pursuant to the state jurisdictions under UNCLOS,” Ocean Policy Research, vol. 33, no. 2, pp. 145-179, 2018 (in Korean).

[https://doi.org/10.35372/kmiopr.2018.33.2.006]

- J. H. Park, “A study on the development and the necessity of law-making of the Maritime Autonomous Surface Ships(MASS),” Master's Thesis, Sungkyunkwan University, Korea, 2019 (in Korean).

- S. H. Park, W. G. Choi, K. Y. Choi, and S. H. Kwon, “Implementation of responsive web-based vessel auxiliary equipment and pipe condition diagnosis monitoring system,” Korean Institute of Navigation and Port Research, vol. 46, no. 6, pp. 562-569, 2022 (in Korean).

-

S. H. Lee, J. Y. Kim, J. J. Lee, Y. Kim, S. Kim, and T. Lee, “A study on the development of database and algorithm for fault diagnosis for condition based maintenance of rubber seal in ancillary equipment of autonomous ships,” Journal of Applied Reliability, vol. 22, no. 1, pp. 48-58, 2022.

[https://doi.org/10.33162/JAR.2022.3.22.1.048]

-

J. B. Yang and D. L. Xu, “On the evidential reasoning algorithm for multiple attribute decision analysis under uncertainty,” IEEE Transactions on Systems, Man, and Cybernetics-Part A: Systems and Humans, vol. 32, no. 3, pp. 289-304, 2002.

[https://doi.org/10.1109/TSMCA.2002.802746]