A study on the developments of STCW training of seafarers on ships applying in the IGF Code

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited

Abstract

The International Maritime Organization (IMO) has been regulating emissions by making mandatory the compliance with institutions aimed at protecting air quality such as the Energy Efficiency Design Index (EEDI), Ship Energy Efficiency Management Plan (SEEMP) and Tier III. Under the circumstances, one of the response measures considered to be the most feasible is the replacement of existing marine fuel with Liquefied Natural Gas (LNG). The industry has been preemptively building infrastructure and developing and spreading engine technology to enable the use of LNG-fueled ships. The IMO, in turn, recently adopted the International Code of Safety for Ships Using Gases or Other Low-Flash-Point Fuels (IGF Code) as an institutional measure. Thus, it is required to comply with regulations on safety-related design and systems focused on response against potential risk for LNG-fueled ships, in which low-flash-point fuel is handled in the engine room. Especially, the Standards of Training, Certification and Watchkeeping (STCW) Convention was amended accordingly. It has adopted the qualification and training requirements for seafarers who are to provide service aboard ships subject to the IGF Code exemplified by LNG-fueled ships. The expansion in the use of LNG-fueled ships and relevant facilities in fact is expected to increase demand for talents. Thus, the time is ripe to develop methods to set up appropriate STCW training courses for seafarers who board ships subject to the IGF Code. In this study, the STCW Convention and existing STCW training courses applied to seafarers offering service aboard ships subject to the IGF Code are reviewed. The results were reflected to propose ways to design new STCW training courses needed for ships subject to the IGF Code and to identify and improve insufficiencies of the STCW Convention in relation to the IGF Code.

Keywords:

IGF Code, STCW seafarer training, LNG-fueled ship, LNG bunkering1. Introduction

The 5th Assessment Report of the Intergovernmental Panel on Climate Change address the severity of global warming. In response, regulations on emissions such as EEDI, SEEMP and Tier III have been made mandatory by the IMO as a preventive measure[1]. The industry including shipping and shipbuilding companies have been devising a wide range of methods to comply with such institutions including the option of using LNG for diesel engines as marine fuel, which has been gaining keen interest as having the highest level of efficiency. In comparison with Bunker C fuel oil, the most widely used fuel oil, LNG as marine fuel is highly eco-friendly, emitting much less Sulfur Oxides, Nitrogen Oxides, Carbon Oxides and fine dust. Also, its price has fallen close to the level of Bunker C fuel oil and is forecasted to drop further due to the impact of shale gas development around the world including the United States (US)[2]. Technological development for propulsion systems powered by LNG has entered the final stage, as witnessed through cases of application to new shipbuilding projects. The prime examples are ME-GI of MAN D&T and X-DF of Wartsila, two of the leading engine manufacturers[3]. As such, LNG-powered propulsion systems will continue to secure competitiveness in terms of environment and cost. They are expected to be applied to almost every type of vessels including containerships, dry bulk carriers, oil tankers, car carriers and passenger ships, raising the need for a variety of on-shore facilities and LNG bunkering vessels[4]. According to a study conducted by Lloyd’s Register, around 2,000 LNG-fueled ships will be operated by 2025[5]. In Korea, several businesses and public corporations are positively reviewing the adoption of a terminal dedicated to LNG bunkering in the Busan New Port and LNG bunkering vessels[6].

However, LNG is a cryogenic material with a large risk of explosion. Its application to most kinds of ships will require special safety facilities and seafarers who have received appropriate training. In this regard, the IMO has carried out around a decade of discussions and studies, adopting the IGF Code in the first half of 2015. The IGF Code defines regulations on facilities and safety for ships that utilize propulsion systems driven by low-flash-point fuel, the leading example being LNG-fueled ships. In addition, IMO amended the STCW Convention by adding relevant regulations such as training required for seafarers that are to provide service aboard ships subject to the IGF Code. Given such developments, it would be timely for the Republic of Korea to amend its Seafarers Act accordingly and devise new training courses to meet the requirements of the STCW Convention.

2. Overview of the IGF code and relevant parts of the STCW convention

2.1 Overview of the IGF Code

The goal of the IGF Code is to provide an international standard on ships that are propelled by gases that are not included in the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk (IGC Code) or low-flashpoint liquids. Considering the properties of such gases and low-flashpoint liquids, it lays out mandatory standards on the installation and deployment of various machinery, equipment and systems under the basic philosophy of minimizing risk on ships, seafarers and the environment. IMO drew up the IGF Code based on extensive understanding of naval architecture, engineering, field experience and data as well as results of research and development. Due to the rapid development of fuel technology, the IGF Code will be regularly reviewed based on new technological trends and field experience.

In principle, the IGF Code deals with all areas that require special review in relation to the use of gases or low-flashpoint liquids as marine fuel based on MSC 1/Circ. 1394. Thus, it defines goals and functional requirements for design, structure and operation that are covered in different chapters.

The current version of the IGF Code mainly focuses on functional requirements for natural gas fuels. However, it will be continuously updated to include requirements for other low-flashpoint fuel in the future[7].

2.2 Overview of STCW Convention in relation to the IGF Code

Section 3 of Annex 5 in the STWC Convention states qualification and training requirements for seafarers who will offer service aboard ships subject to the IGF Code, the latter of which is divided into basic and advanced training.

Basic training is required for all seafarers, but exempted are those issued with certificate for completing the existing basic training on liquefied gas tanker operation. Advanced training is required for ship masters and marine engineers, the certificate of which is issued after satisfying two conditions: successful completion of the advanced training for ships subject to the IGF Code, and more than one month service aboard ships subject to the IGF Code that includes a minimum of three bunkering experiences. However, those issued with certificate for the advanced training on liquefied gas tanker operation are exempted.

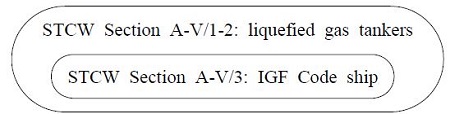

According to the STCW Convention as explained above, the basic and advanced training for ships subject to the IGF Code is included in the scope of basic and advanced training for liquefied gas tanker operations applied to the IGC Code in terms of institutional relationship[8].

3. Design of the basic training for ships subject to the IGF Code

3.1 Trainees

Under the STCW Convention, ship masters, navigation officers, marine engineers and deck and engineering ratings that are to provide service aboard ships subject to the IGF Code must successfully complete the basic training for ships subject to the IGF Code.

3.2 Details of the STCW Convention

STCW Code Part A-V specifies the minimum standard of competence in basic and advanced training for liquefied gas tankers and ships subject to the IGF Code. The basic training for ships subject to the IGF Code is focused on the understanding of basic safety guidelines in consideration of risk posed by LNG that will be mainly used. Therefore, most of its competences are included in the basic training for liquefied gas tankers. Table 1 is a comparison between the two basic trainings in regards to requirements of the STCW Convention, showing the high level of similarity.

Table 1 helps us understand why the STCW Convention exempts those issued with certificate for the basic training for liquefied gas tankers from the basic training for ships subject to the IGF Code[9].

3.3 Proposal for basic training for ships subject to the IGF Code

Taking into account the similarity with the basic training for liquefied gas tankers, the most optimal form of the basic training for ships subject to the IGF Code could be developed. It would be a two-day course based on excerpts out of the existing three-day course for liquefied gas tankers on ships subject to the IGF Code. In addition, for those who need training on liquefied gas tankers after completing the training on ships subject to the IGF Code, a short one-day course consisting of contents unrelated to the IGF Code training could be provided to avoid redundancy. The complementary amendment to the currently training system should be drawn up and reflected to the Enforcement Decree of the Seafarers Act of Korea.

Basic training on liquefied gas tankers (3 days) is needed to consist of basic training on ships subject to the IGF Code (2 days) with short basic training on liquefied gas tankers (1 day) considering Contents overlapping with the basic training on ships subject to the IGF Code are removed

Based on the principles mentioned above, the basic training for liquefied gas tankers given by the Korea Institute of Maritime and Fisheries Technology (KIMFT) could be reorganized into the basic training for ships subject to the IGF Code as seen in Table 2.

4. Design of the advanced training for ships subject to the IGF Code

4.1 Trainees

Ship masters and marine engineers to provide service aboard ships subject to the IGF Code must successfully complete the advanced training for ships subject to the IGF Code and be issued with the corresponding certificate. Unlike in the case of basic training, however, the certificate for advanced training has another prerequisite for issuance, which is work experience aboard ships subject to the IGF Code.

4.2 Details of the STCW Convention

A certain level of work experience aboard ships subject to the IGF Code is a precondition for the issuance of an advanced training certificate under STCW Code Part A-V. In detail, the requirement is more than one month of on-board service that includes at least three bunkering experiences. A supplementary section allows the replacement of two bunkering experiences with a simulated training on bunkering, which is included in the advanced training for ships subject to the IGF Code [8].

Accumulating three bunkering experiences only through overlap seagoing service will take a long period of time for seafarers without experience aboard ships subject to the IGF Code, especially newly-hired junior marine engineers or senior marine engineers who have switched ship type. This is because as with the design of most commercial ships, the bunker tank of ships subject to the IGF Code is designed to require monthly bunkering [10]. Under the circumstances, seafarers without experience on ships subject to the IGF Code need a long period of overlap seagoing service that could also put burden on ship owners. In turn, it will weaken seafarers’ competitiveness to land a job and is highly likely to deter the free transfer between ships subject to the IGF Code and ships not subject to the IGF Code.

In this regard, including two of the three bunkering experience requirement in the advanced training for ships subject to the IGF Code will reduce the overlap seagoing service period and strengthen seafarers’ capability. The most optimal method would be to adopt computer simulation on LNG bunkering to the training course. The US Maritime Resource Center has been providing the LNG PIC (Advanced) Course since May 2015 that involves training on bunkering with a computer simulator [11].

4.3 Problem of exemption by the STCW Convention

According to STCW Annex Regulation V/3, seafarers issued with certificate for the advanced training for liquefied gas tankers who, over the recent five years, have boarded a liquefied gas tanker or ships subject to IGF Code for more than three months, and participated in at least three bunkering experiences are exempted from the advanced training for ships subject to the IGF Code [8]. Simply put, ship masters and marine engineers of existing LNG or Liquid Petroleum Gas (LPG) carriers are free from the advanced training for ships subject to the IGF Code. The problem, however, is that goals and requirements by the STCW Convention differ between advanced trainings for liquefied gas tankers and ships subject to the IGF Code.

Both training share the common underlying goal of enabling safe handling and transport of hazardous materials (gas) such as LNG. Yet, specific equipment and operation expertise to achieve the goal are far apart.

The advanced training for liquefied gas tankers is focused on cargo operation in terms of work procedure and cargo machinery. In contrast, that for ships subject to the IGF Code is centered on gas diesel propulsion system such as new engine types including ME-GI and X-DF, auxiliary systems as well as LNG bunkering operation.

Table 3 introduces an existing course of STCW advanced training for liquefied gas tanker cargo operations. It should be reviewed to confirm whether the minimum standard of competence of the advanced training for ships subject to the IGF Code of the STCW Convention is included.

Exempting experienced seafarers who have completed the advanced training for liquefied gas tankers from that for ships subject to the IGF Code should be based on the assumption that they satisfy the training and experience requirements for the issuance of the IGF advanced training certificate. This should be the basis in reviewing the current situation.

First, it was considered whether the STCW advanced training for liquefied tanker cargo operations provided by KIMFT and its supporting competence of the STCW Convention encompasses the STCW competence of the IGF Code advanced training. The result laid out in Table 4 indicates that many parts are omitted, unlike in the case of basic training. The discrepancy is deemed to emanate from the level of sophistication of contents addressed by the advanced training. Since the two trainings do not form a complete subset relationship, it could be concluded that the exemption provision has legal incoherence.

Competences not included in the advanced training for liquefied gas tankers among competences (STCW Table A-V/3-2)

Thus, it would be reasonable for interested parties and the IMO to reconsider the exemption provision. Also, if necessary, the STCW Convention should be amended accordingly prior to January 1, 2017 when the IGF Code enters into effect.

Second, it was reviewed whether seafarers currently providing service aboard liquefied gas tankers such as LPG or LNG carriers are equipped with the appropriate level of field experience required by ships subject to the IGF Code.

Seafarers who need certificate for the advanced training for ships subject to the IGF Code are ship masters and marine engineers. Confining the review on such positions, most existing LNG carriers are applied with steam turbine engines. Only few ships are equipped with the Dual Fuel Diesel Electric (DFDE) engine. However, ships subject to the IGF Code directly inject high-pressure gas to the diesel engine, which is largely different from engine types generally handled by marine engineers on existing LNG carriers. Although the induction of LNG vapor to the engine room is similar, there remain large difference with LNG carriers regarding fuel gas supply, storage and re-liquefying systems related to the engine combustion method [12]-[15]. Moreover, in terms of competence in LNG bunkering, marine engineers of LNG carriers do not take on direct responsibility and tasks for unloading such as cool-down, vapor control, warming-up and topping-off. Therefore, it is difficult to say that they are entirely familiar with the procedure. The unloading for a LNG tanker is led by navigation officers and deck seafarers, whilst marine engineers control the pressure of cargo vapor and bunker Heavy Fuel Oil (HFO).

Most LPG tankers are equipped with diesel propulsion systems that use general HFO. Thus, marine engineers are not used to the direct gas fuel injection diesel propulsion system, which is the key equipment of ships subject to the IGF Code and auxiliary equipment such as the fuel gas supply, storage and re-liquefying systems. Also, we cannot be sure about their familiarity with the risk of LNG, a cryogenic material of -160 degrees Celsius and unloading is led by navigation officers and deck seafarers. Therefore, we cannot say that they hold an adequate level of experience required to transport LNG on a ship subject to the IGF Code in an uninterrupted manner.

In conclusion, an advanced training for ships subject to the IGF Code that encompasses IGF Code-specific STCW competences not included in the training for liquefied gas tankers, characteristics of ME-GI and X-DF, the most general engines for ships subject to the IGF Code and LNG bunkering simulation is needed. At the same time, the STCW Convention should be amended to make the training mandatory for all seafarers, even those with certificate for advanced training for liquefied gas tankers and work experience, prior to boarding ships subject to the IGF Code.

4.4 Design of the advanced training for ships subject to the IGF Code

As suggested based on legal and technical review, the advanced training for ships subject to the IGF Code needs to be divided into two levels, one for experienced seafarers that have been issued with certificate on the advanced training for liquefied gas tankers and another for those with experience in neither work nor training in regards to liquefied gas tankers and ships subject to the IGF Code.

The training for experienced seafarers that have been issued with certificate on the STCW advanced training for liquefied gas tankers could be designed as proposed in Table 5.

Advanced training for ships subject to the IGF Code (for seafarers that have been issued with certificate for the advanced training for liquefied gas tankers or with experience aboard liquefied gas tankers)

The competences of the STCW Convention and characteristics and technical issues of gas fuel diesel engine were reflected to determine the details of Table 5. Technical issues related to ME-GI of MAN D&T and X-DF of Wartsila, the two most widely discussed engines nowadays, were included as well [15]. The training is formulated to achieve the training goals of the STCW Convention. It will improve practical seafaring capabilities regarding the propulsion and engine systems applied to ships subject to the IGF Code and help seafarers understand all kinds of operations relevant to the IGF Code fuel types including the LNG bunkering operation.

The simulator training that enables LNG bunkering operation is essential in enhancing the practical capability of trainees and for inexperienced seafarers to gain the minimum on-board experience required to be issued with certificate on the advanced training for liquefied gas tankers.

Furthermore, details in Table 5 that are out of context of the STCW Convention are focused on equipment vital in operating ships subject to the IGF Code, especially those that seafarer lack experience with, based on a review on the technical information from engine manufacturers, shipyards and classification societies [16]-[24].

5. Conclusion

5.1 Conclusion on the basic training for ships subject to the IGF Code

As stated before, the adoption of the IGF Code gives rise to the need for relevant STCW training. In this regard, legal ground on the basic and advanced training for ships subject to the IGF Code should be added to the Enforcement Decree of the Seafarers Act of Korea.

The STCW basic training for ships subject to the IGF Code must legally become part of the STCW basic training for liquefied gas tankers as explained. Also, a provision should be established to allow for a short training on liquefied gas tankers that excludes contents from the IGF Code training in the case a seafarer who has completed the basic training for ships subject to the IGF Code is to participate in a basic training for liquefied gas tankers.

5.2 Conclusion on the advanced training for ships applying in the IGF Code

Under the current STCW Convention, those who hold certificates for the advanced training on liquefied gas tankers are exempt from the advanced training on ships subject to the IGF Code. Accordingly, ship masters and marine engineers of LPG and LNG carriers that have been applied with the IGC Code are able to board ships subject to the IGF Code without additional STCW training.

Both ships subject to the IGC Code and the IGF Code are identical in that gas fuels of low flashpoint such as LNG or LPG are combusted in the engine room to propel the ship. However, exempting seafarers from training based on such fact is an approach that is highly risky and insufficient in terms of technical issues.

Most existing LNG carriers are equipped with propulsion systems based on steam turbine or DFDE and LPG carriers with diesel systems that use HFO. Such methods of propulsion show large technological difference with ME-GI or X-DF, the main engines of ships subject to the IGF Code. At the same time, marine engineers of existing LNG and LPG carriers are not fully familiar with LNG unloading. Therefore, the circumstances and background should be reconsidered to create an environment in which only seafarers with enough experience and training provide service aboard ships subject to the IGF Code.

References

- IPCC, IPCC Fifth Assessment Synthesis Report, CLIMATE CHANGE 2014, Sythesis Report, London, p1-15, (2014).

- W. H. Han, “A repercussion on the LNG market due to a slump in the international oil market price”, Quarterly Review of Center for Gas Eonomics & Management, 14(2), p38-59, (2015).

- H. S. Kim, K. P. Kim, and D. H. Kim, “A Status of LNG Fuelled Ship”, Proceedings of the Korean Society Of Marine Environment & Safety Fall Conference, p247-249, (2013).

- M. Wuersig, and A. Chiotopoulos, “LNG today and tomorrow“, DNV-GL Maritime in focus - LNG as ship fuel (Latest developments and projects in the LNG industry), (01), p6-7, (2015).

- Lloyd's Register, LNG-fuelled deep sea shipping (The outlook for LNG bunker and LNG-fuelled newbuild demand up to 2025) : Lloyd's Register, p4-5, (2012).

- J. H. Bae, B. C. Park, S. C. Shin, and S. Y. Kim, “Risk assessment of ship-to-ship LNG bunkering at BUSAN NEWPORT”, Proceedings of the 2014/06 Korean Society Of Marine Environment & Safety Spring Conference, p300-302, (2014).

- IMO, International Code of Safety for Ships using Gases or other Low-flashpoint Fuels (IGF Code), IMO, 1 PREAMBLE (2015).

- IMO, STCW Convention & Codes, Manila Amendments 2011 / STCW Convention / Regulation V/3, IMO, (2015).

- IMO, STCW Convention & Codes, Manila Amendments 2011 / STCW Code Part A / Section A-V/3, IMO, (2015).

- Gas Entec Co., Ltd, Fuel Gas Supply System - Membrane Version (EFGS-M) 3,100 TEU LNG Fueled Container Ship, Gas Entec Co., Ltd, http://www.gasentec.com/bbs/ (2015).

- United States Maritime Resource Center (USMRC), LNG Bunkering PIC (Combined Basic and Advanced) Course, USMRC, http://usmrc.org/training/lng/ (2015).

- E. S. Beak, HHI’ Gas Package Solution, Hyundai Heavy Industry Co,. Ltd, (2014).

- S. K. Kim, “The introduction of MAN B&W M/E and ME - GI engine for LNG carrier”, Journal of the Korean society of Marine Engineering, 29(6), p603-611, (2005).

- K.-M. Kim, J.-H. Jeong, “LNG Fuel Gas Supply System (FGSS)”, Journal of the Society of Naval Architects of korea, 50(4), p40-43, (2013).

- H. S. Kim, K. P. Kim, H. K. Kang, “Technical trends and analysis of LNG fuelled ship”, Proceedings of the Korean Society of Marine Engineering Fall Conference, p223-228, (2012).

- DNV, Standard for Certification No. 3.302 - Competence of Shipboard LNG Cargo Operators, DNV, p7-19, (2006).

- DNV, Standard for Certification No. 3.325 - Competence Related to the On Board Use of LNG as Fuel, DNV, p7-15, (2013).

- Swedish Marine Technology Forum, LNG bunkering Ship to Ship procedure, No. LNG02 : Swedish Marine Technology Forum, (2014).

- Korean Register of Shipping, Guidance for Gas-Fuelled Ships, Korean Register of Shipping, (2013).

- S. B. Cha, “ME-GI MAN B&W dual fuel engine”, Proceedings of the 2010 Korean Society of Marine Engineering Conference, p73-75, (2010).

- H. S. Eom, “Development of marine dual fuel engine simulator”, Journal of Korean Institute of Information Technology, 10(6), p15-22, (2012).

- S. K. Kim, “The introduction of MAN B&W M/E and ME-GI engine for LNG carrier”, Journal of the Korean Society of Marine Engineering, 29(6), p603-611, (2005).

- N. B. Clausen, “Alternative propulsion for LNG ships by low speed ME-C and ME-GI engines”, Proceedings of the Korean Society For Power System Engineering 2006 Fall Conference, p48-61, (2006).

-

Y. H. Lee, Y. T. Kim, H. K. Kang, “An analysis on the characteristics of regasification system for gas fuelled ship depending on the mixing ratio of eglycol and water”, Journal of the Korean Society of Marine Engineering, 38(7), p799-805, (2014).

[https://doi.org/10.5916/jkosme.2014.38.7.799]