A study on combustion of blended straight vegetable oil in marine diesel engine cylinders

Copyright ⓒ The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Straight vegetable oil (SVO) is widely recommended as fuel for diesel engines in general and especially for marine diesel engines. However, SVOs used directly as fuel for diesel engines may cause problems for the engines; SVOs blended with diesel oil are a better choice. To widen understanding of the possibility of using blended SVOs as fuel alternatives, this paper presents results of experimental research on the combustion of blended straight vegetable oil in a marine diesel engine’s cylinders. Results show that the fuel combustion process have the same curves as in simulations and, in the case of using blended fuels with up to 20% palm oil, the test diesel engine technical parameters such as engine output, exhaust gas temperatures, and specific fuel consumption are very similar to those of diesel oil (DO). Based on these results, marine diesel engines are strong potential applications and particularly recommended for the use of SVO blends.

Keywords:

Straight vegetable oil, Blended Fuel, Combustion process, Marine diesel engine1. Introduction [1]

The tendency towards using renewable fuels such as gas fuel(LPG, NLG) and bio-fuel in the maritime sector is firmly established. Most well-known marine engine makers have focused attention on applied research and development relating to renewable fuels. However, using these fuels widely on a commercial scale is not yet feasible. This is because the cost of bio-diesel is still high and the safety required for gas fuel use onboard is very complex. Among renewable fuels, a fuel with more potential is straight vegetable oil (SVO). SVO has also been used as alternative fuel for on-shore operating diesel engines as well as for offshore engines owing to its reasonable fuel price, which is slightly higher than for conventional diesel oil (DO). Nevertheless, the practicality of using SVO as alternative fuel for marine diesel engines needs to be confirmed. With this aim, we carried out an investigation on combustion of SVO and its blend with DO fuel inside cylinders of a medium-sized marine diesel engine.

2. Straight vegetable oil as alternative fuel for diesel engines [1][2]

The first diesel engine, which was invented by Rudolf Diesel, used straight vegetable oil (SVO) as fuel. Since their invention in 1892, diesel engines have been improved and have become highly efficient. Almost all existing diesel engines are designed to be optimized for fossil fuel and they are not able to attain optimum combustion processes with other kinds of fuel such as SVO. However, due to a shortage of conventional fuel resources in the near future and environmental protection issues, SVO is again being recommended as an alternative fuel, especially for marine diesel engines. Hence, it is necessary to clarify the properties of straight vegetable oils and their differences in comparison with standard diesel fuel in order to bridge the gap between them.

Firstly, SVO refers to all kinds of vegetable oils produced for fuel purposes. Production of SVO is quite simple, involving mechanical extraction of oil from an oil-bearing biomass as feedstock. The quality of SVO for fuel use depends on the feedstock and processing conditions. SVOs have a chemical composition of triglycerides, mainly consisting of one glycerol combined with three molecules of fatty acids. The latter contain long chains of carbon atoms linked by single bonds and combined with hydrogen, ending with a carboxyl group. Meanwhile, fossil fuel oils are complex mixtures of hydrocarbons which contain paraffins, naphthenes, olefins, and aromatics. SVOs have some advantages over other fuel oils for marine diesel engines, including renewability, local availability, lower sulfur content (avoiding environmental issues caused by sulfuric acid), lower aromatic content, and high biodegradability [2]. However, SVOs also have several disadvantages, such as high viscosity, low cetan number, and high fatty content, influencing the fuel injection process and causing engine coking if misused.

3. Combustion of SVO blends with diesel oil

3.1 Theoretical investigation

The main aim of the theoretical part of our investigation is to calculate some important parameters of fuel combustion inside a cylinder on the basis of a mathematical model of a diesel engine. There are several different types of mathematical model of diesel engines such single-zone, two-zone, and multi-zone models with advantages and disadvantages. However, the single-zone model was selected to support this research.

The single-zone model was developed on the basis of the first law of thermodynamics, which states that “the change of internal energy inside a closed system is equal to total input energy minus the energy converted into work.” If a diesel engine is considered as a closed system and we investigate the energy change of the system over a very small crank angle, then energy conservation in accordance with the first thermodynamic law can be expressed as follows [3]-[5]:

| (1) |

where ∂Q is the heat released when fuel is burned [kJ/oCA], ∂W = PdV is work created [kW], and dU = mCvdT is the speed of the internal energy change.

Then we can write equation (1) in a new form:

| (2) |

equation (2) can then be applied for an ideal gas and converted into a differential equation depending on the engine crank angle and, using some related relations such as R = CP – Cv and k = CP / Cv , the conservation equation can be written as follows:

| (3) |

Equation (3) is a general form for calculating pressure changes and heat released by burning fuel inside a diesel engine cylinder.

Then, based on the equation (3), the equations for estimation of pressure changes and heat release during fuel burning inside a cylinder are as follows:

• Pressure in cylinder

| (4) |

where Qin is the energy input [equation (5)] in [kJ/kg] and dV/dθ is the change of cylinder volume depending on crank angle calculated by equation (6):

| (5) |

| (6) |

• Heat release

If Qgross is real heat released then Qgross =Qnet – Qloss Here Qnet is total energy input to a cylinder and Qloss is energy lost to the surroundings. Then a differential equation for the real heat release can be created as follows:

| (7) |

The lost energy can be expressed by equation (8):

| (8) |

The Reynolds number is defined as:

where ac=0.38 (for a two-stroke engine) and 0.49 (for a four-stroke engine), b=0.7, and cr = 1.6 × 10-12.

The net input energy is calculated by below equations:

| (9) |

Here, dm/dθ is burned gas lost through the piston rings and is the mass of fuel injected into the cylinder. The relation between m and is expressed by equation (10):

| (10) |

where C=0.8 [m/s] is a constant and Sp is the average speed of the piston.

Combustion temperature

Based on the first law of thermodynamics, equation (1) can be expressed as:

| (11) |

where m is the mass of the burned mixture supplied into the cylinder [kg], is the speed of internal energy increase, is the heat release speed of fuel burned [kJ/0CA]; and is the speed of work creation.

However, in fact, the energy which is supplied into a diesel engine by burning fuel causes not only an increase of the internal energy but a part of this energy is also lost to the surroundings owing to heat transmission (dQloss/dθ). Therefore, equation (11) can be expressed as follows:

| (12) |

Then, a mathematical model to calculate the combustion temperatures inside a diesel engine cylinder can be equationted as:

| (13) |

where m can be canculated by using the relation PV=mRT, Cv is the specific heat at constant volume [KJ/(kg.K)], and for the gas in the model, Cv = 1,008 [KJ/(kg.K)].

• Ignition delay

The blended SVO usually has a cetan number lower than that of fossil diesel oil and the cetan number itself influences the ignition delay of fuel; the ignition delay then determines the entire combustion process in the cylinder. Therefore, identifying ignition delay of fuel inside an engine cylinder is very important because, if ignition delay of the fuel is known, the fuel injection time can be adjusted properly for a diesel engine. The ignition delay of a fuel can be calculated on basis of a mathematical model. According to experts’ research results, an ignition delay model is influenced by two factors: the physical processes presented by pressures /p/ and temperatures /T/ of combustion mixtures inside the cylinder combustion chamber; and chemical process considerations such as the activation energy EA. Consequently, two scientists, Hardenberg and Hase, have proposed a model of ignition delay as follows [3]:

| (14) |

Here τid is the ignition delay time [s] or [oCA], is the average speed of the piston [m/s], EA is the activation energy [kJ/mol], Tcyl is the temperature of the burned mixture inside the cylinder [oK], Pcyl is the pressure of the burned mixture inside a cylinder [Pa], and R=8.314 [J/mol.oK] is the real gas constant.

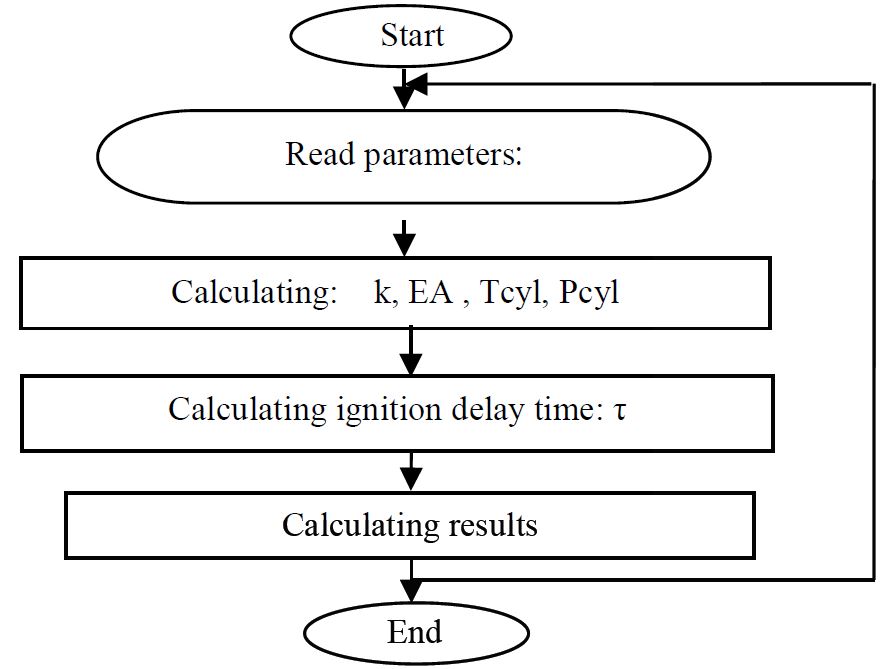

For identification of ignition delay time of a fuel, a calculation algorithm was developed as showed in Figure 1[6][7].

3.2 Experimental investigation

Experimental research is absolutely necessary in order to conclude whether SVO and SVO blends can be used as fuel for marine diesel engines. The experimental part of this study was carried out at the Research Center of Marine Diesel Engine (Vietnam Maritime University) [6].

Palm oil was selected as a straight vegetable oil for research and blended palm oil was produced by a continuous fuel mixer which was designed and manufactured by our research team. A medium-sized marine diesel engine 6LU32 (Hanshin-Japan) used as the engine in this study is a four-stroke engine with a turbocharger. This diesel engine drives a hydrodynamic brake which acts as load consumption equipment. Objectives of this experimental research include identifying the actual combustion of blended palm oil (with different amounts by volume of palm oil in the fuel mixture) inside engine cylinders and determining the ignition delay time depending on the percentage of palm oil in fuel mixtures. Furthermore, through special observation equipment called a VisioScope, pictures of combustion occurring inside a cylinder chamber were taken. The real visual pictures of blended palm oil combustion can provide valuable conclusions and recommendations regarding the use of SVOs as fuel for marine diesel engines.

For the purpose of this study, the technical specifications of the 6LU32 diesel engine and the fuel features of blended palm oils are shown in Tables 1 and 2.

In order to avoid confusion with blended bio-diesel fuel, in this paper PO denotes blended palm oil. PO5 means that the fuel mixture contains 5% palm oil while the remaining amount is DO (95%). PO100 is pure palm oil (0% DO).

4. Results and discussions

4.1 Model investigation results

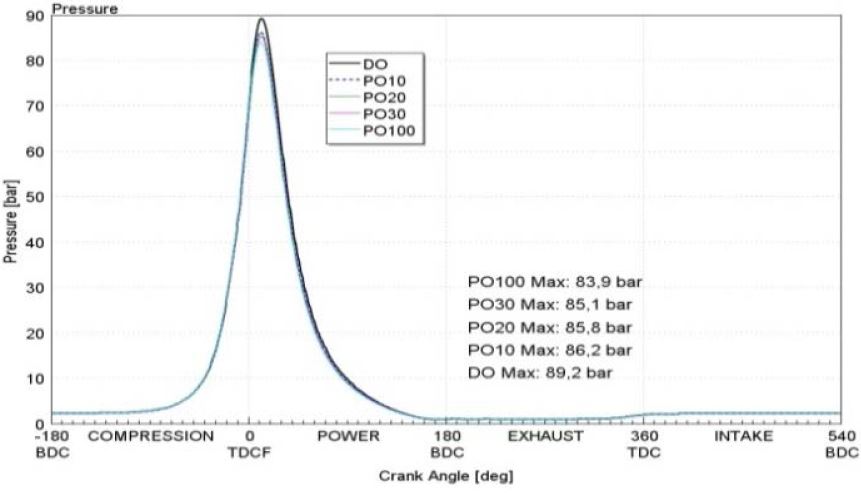

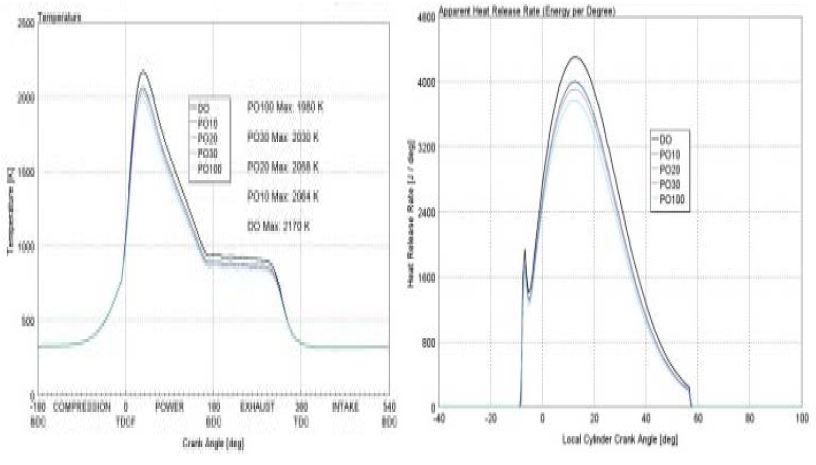

Based on the equations (4), (7), (13), our reasearch team simulated the combustion of blended palm oil at three different loads, namely 100%, 75%, and 50%. Results of the model calculations are presented in Figures 2, 3, and 4.

To analyze the simulation results in detail, we broke down the data into real values of combustion pressure, heat release, and temperature in accordance with different kinds of blended fuels. These are presented in Tables 3, 4, and 5.

In Table 5, results of ignition delay of blended fuels obtained by the model calculation (equation (14)) are shown. Additionally, a comparison is made between the ignition delay times in Table 6.

The calculation results for fuel combustion inside diesel engine cylinders show that:

- The combustion of blended fuels is very similar to that of DO fuel. Owing to presence of palm oil in the blends, combustion parameters such as pressure, temperature, and heat release rate are lower than those of DO.

- Differences can be seen most clearly between the combustion of PO100 and DO, but become less clear when engine load is reduced. The gap in peak pressures at 100% load is 5.94% and 3.43% at 50% load;

- The greater the percentage of palm oil in blends, the smaller the output of the engine owing to the lower specific heat of the blended fuel.

- PO100 has the highest ignition delay in comparison with that of DO, measured at a value of 0.101oCA, equivalent to an increase of 4.595% relative to DO. The differences of ignition time for blends are not very large: 0.6% for PO10 and 1.365% for PO30.

4.2 Experimental results

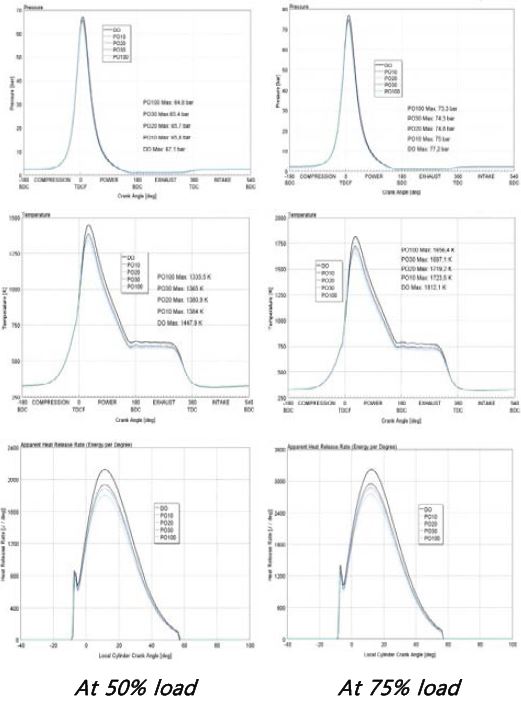

Experimental research was also carried out on a real 6LU32 marine diesel engine with the support of high-accuracy measuring equipment. Measurements were taken for combustion pressure, temperature, heat release rate, and ignition delay time in two regimes: 50% load and 75% load.

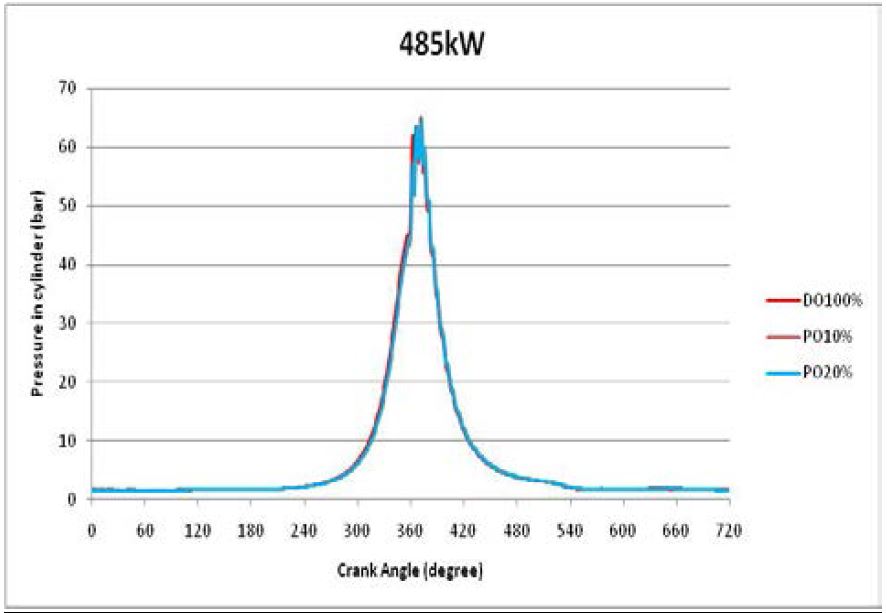

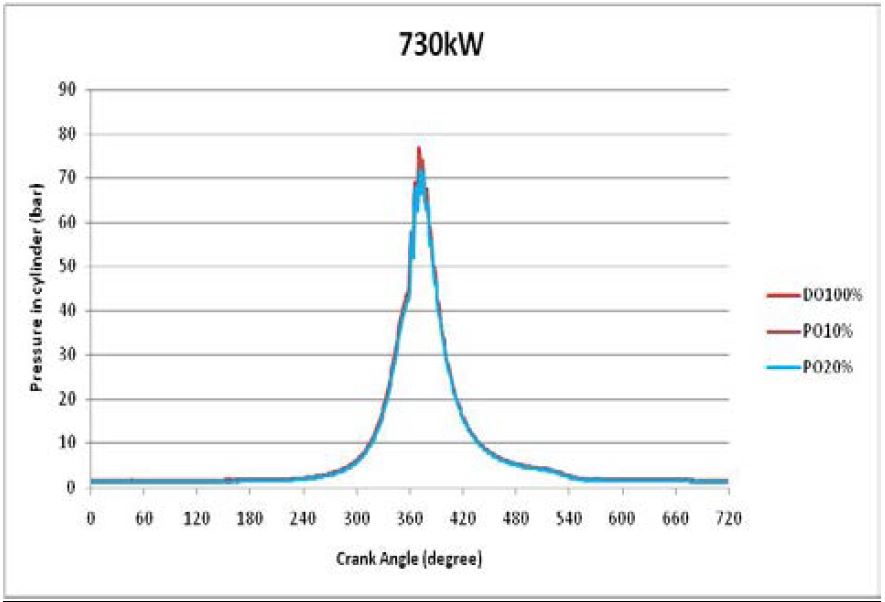

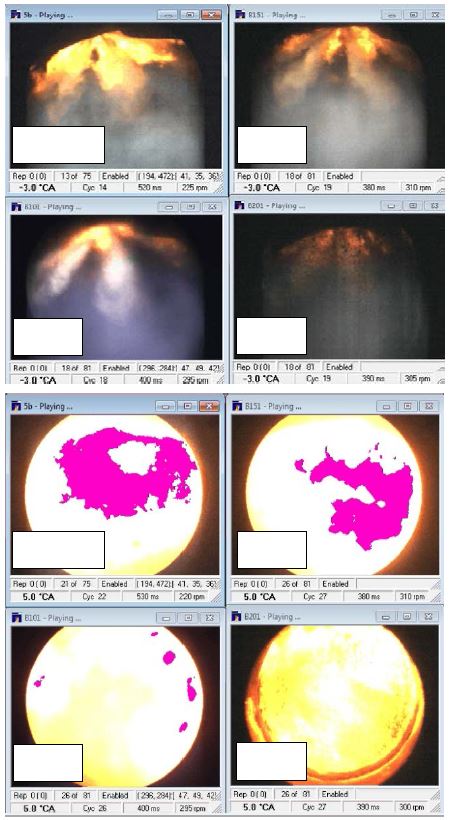

• Peak pressure

The characteristics of combustion pressure changes are shown in Figures 5 and 6 and details are presented in Table 7.

Changes of pressure in cylinders for all blended fuels and DO were the same. The biggest difference of peak pressure is recognized for PO20 relative to DO, with a value of 5.58%.

It can be seen that the ignition start of PO10 before top dead center (TDC) was the same as that of DO at low load and was delayed by 1.31 times at higher load. Also, the delay increased approximately linearly with rising volume fraction of palm oil in the blended fuels.

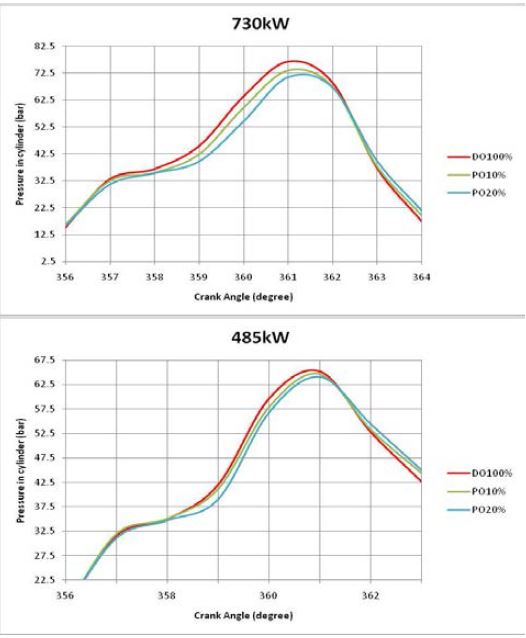

To demonstrate this result, the VideoScope equipment was used to observe the combustion process in the cylinder, especially at the start of ignition, for different kinds of blended fuels including DO, PO10, PO15, and PO20. The results are shown in Figure 8.

• Ignition delay

The results of ignition delay of blended palm oil are shown in Figure 7. The research team enlarged pictures of the moment of starting ignition for all kinds of tested blended fuels, and real values measured are presented in Table 8.

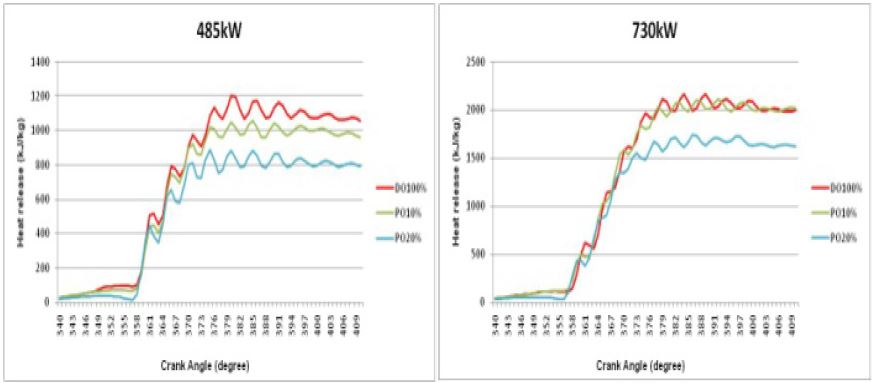

• Heat release

The heat release was recorded and is presented in Figure 9. At the lower load (50%), the heat release of the fuels is more different than at the higher load (75%). The highest heat release was for DO and the lowest was for PO20. However, the variance was not large at the higher load.

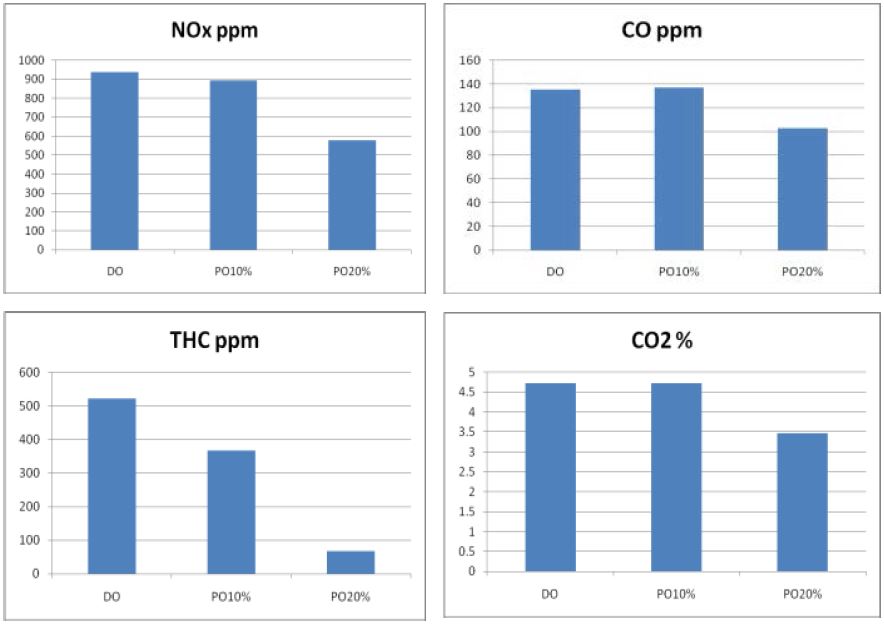

• Emissions

Emissions in the exhaust gas of diesel engines such as CO, CO2, HC, and NOx were analyzed by a special AVL AMA i60 R1 measuring system. The results of the experiment are plotted in Figure 10.

Among emissions, for the marine field, IMO focuses seriously on NOx content control. The absolute values of NOx in the experiment associated with different fuels are shown in Table 9.

The results show that the greater volume fraction of palm oil in the blended fuels, the lower the NOx emissions in the exhaust gas of the diesel engine. In particular, the NOx emissions of PO20 were only 13.6 [g/kW.h], which was lower than the allowable NOx emissions limit requested by IMO for the 6LU32 test diesel engine with nominal operation at 320 rpm (requested NOx emission for the test engine is 14.19 g/kW.h).

5. Conclusion

Use of straight vegetable oil is becoming more wide-spread in the maritime field owing to important advantages of SVO as a fuel alternative. However, SVO which is used directly as fuel for marine diesel engines may cause problems for engines such as bad combustion, engine coking, significantly lower output, and so on. Therefore, to avoid the above mentioned problems, it is recommended that blended SVOs should be applied. In order to understand more clearly the possibility of using blended SVOs on basis of the above research results, the following conclusions were found:

- The combustion process of blended palm oil fuels is very similar to that of diesel fuel (DO), as presented in Figures 3 and 6. The study results achieved by model calculations and by experiment showed that the maximum pressure and the heat release of blended fuels are slightly lower than those of DO.

- The difference in ignition delay times of varied SVO blends greatly affect the burning process. Therefore, the volume of palm oil in blends should not exceed 20%.

- Impressive results associated with exhaust gas emissions were recorded for the blended fuels, as well. The content of CO, CO2, THC, and NOx decreased with the increasing fraction of palm oil in the blends.

Finally, blended SVOs (palm oil and others) can be used as alternative fuels not only for diesel engines in general, but also for marine diesel engines in the near future.

References

- K. Kołwzan, M. Narewski, and P. R. Statków, “Study on alternative fuels for marine applications”, Clean Shipping Currents, 1(3), (2012).

- J. Blin, C. Brunschwig, A. Chapuis, “Characteristics of vegetable oils for use as fuel in stationery diesel enginestowards specification for a standard in west Africa”, HAL archives-ouvertes, (2013).

- J. B. Heywood, Internal Combustion Engine Fundamentals, McGraw-Hill Book Company, (1988).

- B. Challen, and R. Baranescu, Diesel Engine Reference Book, Butterworth-Heinemann, Oxford OX2 8DP (1999).

- P. A. Lakshminarayanan, Y. V. Aghav, Modelling Diesel Combustion, Springer, (2009).

- D. V. Uy, and research team, “Research and develop a technology solution in order to convert marine diesel engines of small and medium scale to use blended straight vegetable oils as alternative fuel”, No.04.11/NLSH (2014).

- N. P. Quang, “MATLAB & SIMULINK for automatic control application”, Scientific and technical Publishing, (2003).