Liquid level measurement system using capacitive sensor and optical sensor

Measurement of liquid level in storage and processing vessels, tanks, wells, reservoirs and hoppers is commonly needed. The several different ways to measure the liquid level of oil or water tank have been provided such as an electrostatic capacity, a supersonic waves and an optical science etc. In the study, we have constructed the stable and efficient measurement system to measure the level of liquid at real-time and to get accurate measurement of the maximum and minimum level of the tank. For this purpose, we suggest double sensing methods by adopting both capacitive and optical sensing. The experimental results, presented in this paper, illustrate the effectiveness of the proposed method under different sensing methods.

Keywords:

Liquid level measurement, Double sensing, Optical sensor, Capacitive sensor1. Introduction

Liquid level measurement system plays an important role in the commercial and technological applications. There is a great diversity of situations, which require level measurement, ranging from pure water to viscous, sticky and corrosive fluids. The environment for level sensors varies from vacuum to high pressure and from below zero Celsius degree to high temperature. Because of the involvement of different situations, many types of level sensors have been developed [1].

The several different ways to measure the liquid level of tank have been provided such as mechanical, capacitive, inductive, ultrasonic [2], acoustic [3] or optical [4]-[6]. The basic principle that must be considered in selecting the detection method is the property of the material that will be detected. For example, mechanical and ultrasonic methods are used to detect the level of solid materials that are in the form of dust. Capacitive and optical methods give better results in detecting the level of fluids [7].

The operating principle of capacitive liquid-level sensors depends on the type of liquid [8]. For conductive liquids, at least one of the two sensor electrodes must be insulated in order to avoid a short circuit. The use of capacitive sensors for liquid level measurements has the following advantages: low cost (i.e. sensors can be built with affordable technologies), low power consumption, high linearity, and easy adjustability to the geometry of the application [9].

For inflammable fluids, optical methods for liquid level measurements are more appropriate since light does not have any effect on the material that is to be detected. Also optical methods are quite simple and can be adapted to any medium easily [7].

In this paper, we describe the design and implementation of a liquid level real-time measurement system based on optical and capacitive sensing techniques. Our sensor system consisted of three parts: the sensor made by the electrodes along the tube and LED-phototransistor; the capacitance-to-frequency converter; and the measurement data acquisition and visualization system using DAQ board and LabVIEW program.

2. Structure and Principle of Sensor

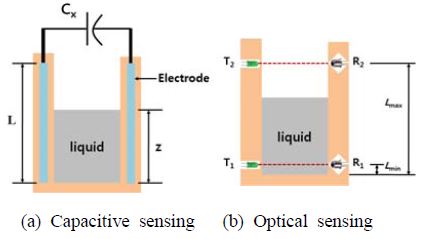

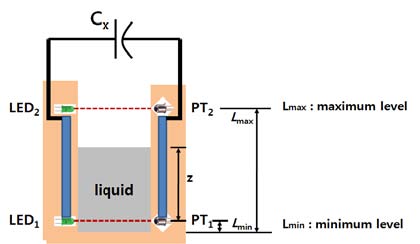

Figure 1 shows a sensor configuration of the level detection method. The capacitive sensor in our study was constructed by attaching copper film on the outer surface of the acrylic tank in Figure 1(a). The electrodes consisted of two rectangular-type metal films for sensing capacitor. The height and width of two electrodes are 200 ㎜ and 20 ㎜, respectively.

Two pairs of LED light source and phototransistor are reciprocally placed at the bottom and the top of the tank in Figure 1(b). The material whose level will be detected is inserted between reciprocally placed LED and photodetector. When the liquid is placed between LED and the phototransistor, LED light cannot reach to the phototransistor because of long distance between LED and phototransistor. On the other hand, When there is no liquid between LED and phototransistor, the phototransistor can detect LED light.

The sensor configuration of the level detection method

Figure 2 shows the proposed sensor configuration for the liquid level detection using double sensing method. The capacitive sensing of the sensor is to measure the liquid level in real-time and the optical sensing using LED and phototransistor is to make warning signals under emergency circumstances such that liquid reaches at the bottom and the top of tank.

The proposed sensor configuration for double sensing of the liquid level

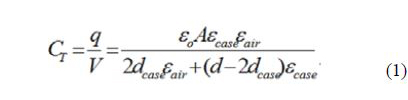

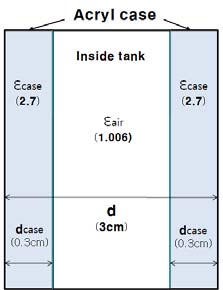

Figure 3 shows the tank configuration with case thickness. The sensor capacitance directly depends on the thickness and the dielectric constant of the insulation. Actually, the capacitance of sensor structure in Figure 3 is dependent upon the casing dielectric properties and thickness. Because the case of tank has 30 ㎜ thickness, the capacitance value of the sensor can be calculated from Equation (1).

Configuration of tank with case thickness

where ε0 is the electric permittivity of vacuum (= 8.855×10−12 F/m), εcase and εair are the relative dielectric constant of the case and the air, respectively, d and dcase are the total width of tank and the thickness of case, respectively and A is area of the two electrodes . From Equation (1), for εcase = 2.7 and εair = 1.006, A = 4000 ㎟, d = 30 ㎜ and dcase = 3 ㎜, the calculated capacitance is 13.5 ㎊, which means no liquid in the tank.

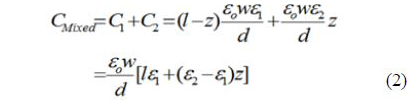

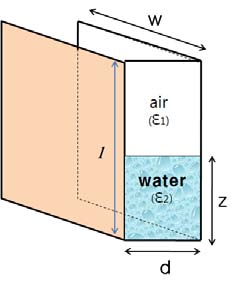

Figure 4 shows the configuration for capacitance calculation according to water level in the tank. An electrical capacitance exists between two electrodes separated by a distance, d. Because the relative dielectric constant of air and water in the tank are different, the value of the modified capacitance can be calculated from Equation (2). The two portions of the capacitor act as parallel capacitors since they share the same electric field. C1 and C2 are the capacitance contributions due to ε1 and ε2 respectively. The amount of capacitance here is determined not only by the spacing and area of the electrodes, but also by the electrical characteristic (relative dielectric constant, ε) of the insulating material.

Configuration for capacitance calculation according to water level in the tank

3. Sensor Measurement System

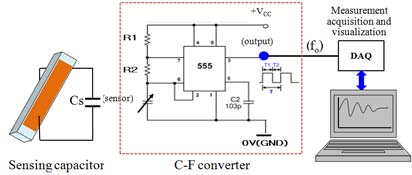

The sensor can be divided into three principal parts as shown in Figure 5: the measurement head made by the electrodes along the tube; the capacitance- to-frequency converter; and the measurement data acquisition and visualization system using DAQ board and LabVIEW program [10].

Configuration for sensor measurement system

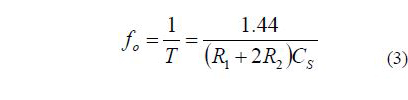

The 555 timer produces a ‘square wave’. This is a digital waveform with sharp transitions between low (0V) and high (+VCC). The timer uses the sensor’s capacitance to create a square wave form [11]. A basis frequency is selected to correspond with the sensor’s capacitance at a given liquid. The C-F converter circuit can transfer the capacitance changes into the resonance frequency (fo) shifts by the expression (3).

where

fo: resonance frequency (㎐);

T: time period in seconds (s);

R1: resistance in ohms (Ω);

R2: resistance in ohms (Ω);

CS: capacitance in farads (F).

The capacitance variation due to the change of water level can lead to the output frequency change correspondingly. Simultaneously the output frequency fo is then fed to the data acquisition and visualization system which is based on a 14-bit A/D data acquisition board, National Instruments PXI-6133, connected to a personal computer. A dedicated program written in LabVIEW allows the continuous visualization over time of the measured signals in order to estimate liquid level.

4. Experimental Results

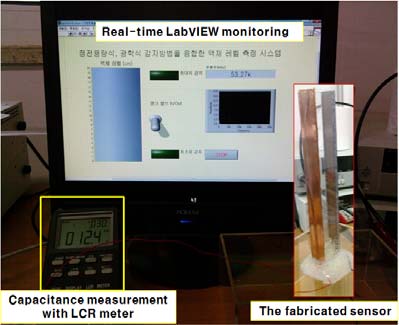

Figure 6 shows the implementation of prototype of liquid level sensor which consists of the fabricated sensor, LCR meter for capacitance measurement and real-time LabVIEW monitoring system. For minimum and maximum level of the tank, the front panel of the system provides two green LED buttons on LabVIEW monitoring display by optical sensing through LED and phototransistor. When liquid reaches to the maximum level, the upper green button will be turn on and when liquid reaches to the minimum level, the lower green button will be turn on.

The implemented prototype of liquid level sensor

Table 1 shows the measured capacitance according to liquid level during increasing time and decreasing time of liquid level. CI is the capacitance when liquid level is increasing and CD is the capacitance when liquid level is decreasing. It can be observed that the capacitance difference between CI and CD is below 5% for all the tested values. The reason for this difference is the “flow-back phenomenon” [12]: when the liquid level decreases, it leaves a residual water on the surface of inner tank that causes the capacitance of the sensor to indicate a different value that expected. This flow-back film depends on the viscosity, density, and surface tension of the liquid.

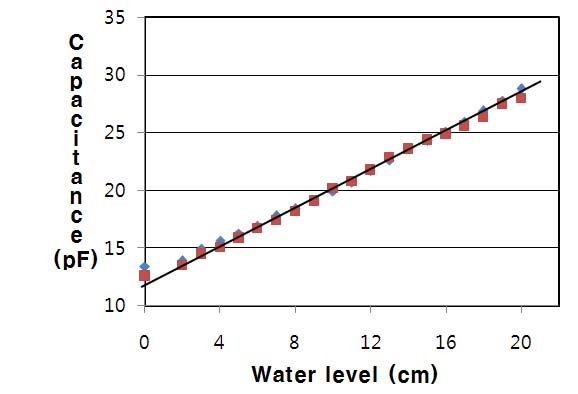

Figure 7 shows the resulting plot of the measured capacitance for different levels of water in the range between 0 ㎝ and 20 ㎝. The sensitivity of the sensor is about 0.77㎊/㎝ in the range of water level between 0 to 20㎝.

The measured capacitance according to liquid level during increasing time and decreasing time of liquid level

Compared to the calculated capacitance from Equation (1), the measured capacitance of 13.4 ㎊ almost matches the calculated capacitance of 13.5 ㎊ when there is no liquid in the tank. This result shows acceptable linear property for water level measurements.

The measured capacitance of the sensor according to water level

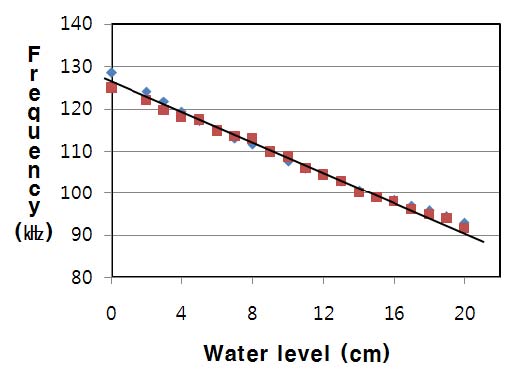

Figure 8 shows the resulting plot of the converted output capacitance of the sensor according to water level by using C-V converter as shown in Figure 5. The sensitivity of the sensor is about 1.88㎑/㎝ in the range of water level between 0 to 20㎝.

The converted output capacitance of the sensor according to water level

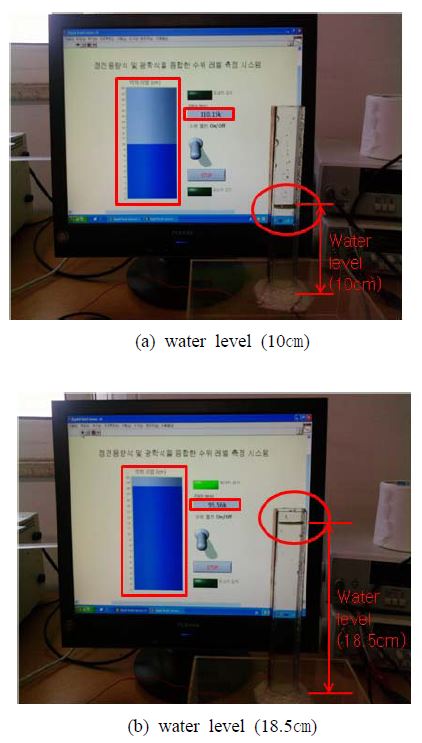

Figure 9 shows the real-time monitoring of the LabVIEW system according to water level. The LabVIEW system allows the continuous visualization over time of the measured values, the associated water levels and green button of maximum and minimum level of tank. When water was filled in the tank at water level of 10 ㎝, the monitor system displays the water level on the front panel. When water was filled in the tank at water level of 18.5 ㎝, the system displays not only the water level but also turn-on of green button for maximum level on the front panel. That is why the maximum level of this system was set up at water level of 18.5 ㎝. The sensitivity of the sensor is about 1.88 ㎑/㎝ in the range of water level between 0 to 20㎝. The overall results show that the sensor is fully acceptable for liquid-level measurements.

Real-time monitoring of the LabVIEW system according to water level

5. Conclusion

In this study, we suggested the stable and efficient measurement system to measure the level of liquid at real-time and to get accurate measurement of the maximum and minimum level of the tank. The proposed sensor used double sensing methods by adopting both capacitive and optical sensing. The sensor output was measured in the range 0 to 20 ㎝. The measured sensitivity was 0.77 ㎊/㎝ in capacitance and 1,88 ㎑㎝t in frequency. In spite of the simplicity of the designed prototype, the characteristics of the sensor showed acceptable results such as sensitivity, linearity, real-time monitoring. The results also demonstrated that the capacitance is altered slightly but the error is acceptable for many applications. The proposed sensor can use to measure exact liquid level of the tank in the fields of offshore plant industry.

Notes

References

-

S. F. A. Bukhari, and W. Yang, “Multi-interface level sensors and new development in monitoring and control of oil separators”, Sensors, 6(4), p380-389, (2006).

[https://doi.org/10.3390/s6040380]

- E. J. Chern, and B. B. Djordjevic, “Nonintrusive ultrasonic low-liquid-level sensor”, Meterials Evaluation, 48(4), p481-485, (1990).

-

K. Shannon, X. Li, Z. Wang, and J. D. N. Cheeke, “Mode conversion and the path of acoustic in a partially water-filled aluminum tube”, Ultrasonics, 37(3), p303-307, (1999).

[https://doi.org/10.1016/S0041-624X(99)00006-2]

-

N. B. Manik, S. C. Mukherjee, and A. N. Basu, “Studies on the propagation of light from a light-emitting diode through a glass tube and development of an optosensor for the continuous detection of liquid level”, Optical Engineering, 40(12), p2830-2836, (2001).

[https://doi.org/10.1117/1.1417496]

-

C. Yang, S. Chen, and G. Yang, “Fiber optical liquid level sensor under cryogenic environment”, Sensor and Actuators A: Physical, 94(1-2), p69-75, (2001).

[https://doi.org/10.1016/S0924-4247(01)00663-X]

-

D. J. Weiss, “Fluorescent optical liquid-level sensor”, Optical Engineering, 39(8), p2198-2213, (2000).

[https://doi.org/10.1117/1.1305539]

-

E. Musayev, and S. E. Karlik, “A novel liquid level detection method and its implementation”, Sensors and Actuators A: Physical, 109(1), p21-24, (2003).

[https://doi.org/10.1016/S0924-4247(03)00347-9]

- G. Vass, “The principles of level measurement”, Sensors Magazine, 17(10), p1-6, (2000).

-

F. Reverter, X. Li, and G. C. M. Meijer, “Liquid-level measurement system based on a remote grounded capacitive sensor”, Sensors and Actuators A: Physical, 138(1), p1-8, (2007).

[https://doi.org/10.1016/j.sna.2007.04.027]

-

K. H. Kim, and J. H. Shim, “Air detector using the change of dielectric constant for medical applications”, Journal of the Korean Society of Marine Engineering, 34(6), p864-870, (2010).

[https://doi.org/10.5916/jkosme.2010.34.6.864]

- D. G. Cinthiya, and R. Jegan, “A novel seat occupancy detection system based on capacitive sensing for airbag control”, International Conference on Emerging Technology Trends, p1-3, (2011).

-

L. B. Wilner, “Variable capacitance liquid level sensor”, Review of Scientific Instruments, 31(5), p501-507, (1960).

[https://doi.org/10.1063/1.1931234]