Nuclear propulsion in cargo ship: A Pathway to the future of emission-free shipping?

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Maritime transportation, responsible for over 80% of global freight movement, is a major contributor to environmental emissions, making the development of effective emission reduction strategies crucial for the protection of marine ecosystems. As regulatory pressures, environmental concerns, and resource efficiency take center stage, alternative fuels such as hydrogen, LPG, ammonia, LNG and biofuels, along with nuclear power, have gained significant attention in the maritime industry. Nuclear energy, in particular, has emerged as promising alternative for reducing carbon emissions in marine vessels, aligning with the International Maritime Organization’s (IMO) decarbonization and fuel efficiency targets. While nuclear-powered vessels have been deployed in icebreaker, naval, and supply sectors, their use remains limited, primarily due to restricted operational ranges. This paper offers a thorough analysis of nuclear-powered cargo ship generation methods, reactor technologies, and safety protocols. Strengthening collaboration between regulatory bodies, pilot projects, and stakeholders is essential for refining safety standards and ensuring regulatory compliance. Public acceptance is another key factor, requiring transparent environmental impact assessments and proactive communication to foster trust and align nuclear-powered vessels with global sustainability objectives. Despite existing challenges, nuclear propulsion presents opportunities for innovation and international cooperation. By addressing regulatory and societal barriers through coordinated efforts and policies, nuclear power could become a cornerstone of the maritime industry's transition to a sustainable, efficient, and technologically advanced future. Its successful implementation would play a vital role in advancing low-carbon shipping and contributing to the broader global energy transition.

Keywords:

Nuclear powered ship, Net-zero emissions, Future shipping, Emission control1. Introduction

Maritime transportation is fundamental to global trade and supply chains, but its large-scale operations contribute substantially to environmental pollution [1][2][3]. The sector accounts for nearly 30% of nitrogen oxide (NOx) emissions and around 2.5% of global carbon dioxide emissions, significantly affecting air quality and contributing to atmospheric pollution [4]. To address these environmental challenges, the International Maritime Organization (IMO) and regional maritime authorities have implemented stringent emissions regulations and standards, such as IMO 2020, MARPOL 73/78, and IMO Tier I, II, and III [5][6][7][8]. Nuclear propulsion is a promising technology for reducing carbon emissions in shipping [9]. It offers a unique advantage as the only zero-emission propulsion system for ocean-going vessels, producing no CO₂, CH₄, NOₓ, SOₓ, or particulate matter during power generation [10]. While this technology warrants deeper investigation, minor air pollutant emissions may still result from fossil fuel use in nuclear fuel extraction, processing, and handling [11].

Currently, approximately 700 nuclear naval reactors have been deployed globally, primarily for military applications, with around 200 still in active operation [12]. This extensive use demonstrates that nuclear reactors offer greater operational reliability than traditional diesel engines. Nuclear propulsion also enhances design flexibility for ships due to its smaller reactor size, and it supports more adaptable operations, as nuclear vessels require less frequent refueling [13].

Gabbar et al. [14] analyzed four distinct energy systems for marine vessels: the ‘Stand-alone fossil fuel-based energy system’, ‘Stand-alone nuclear energy system’, ‘Renewable and fossil fuel-based hybrid energy system’, and ‘Nuclear-renewable hybrid energy system (N-R HES)’. The analysis is based on several key performance indicators (KPIs), including the net present cost (NPC), cost of energy (COE), and greenhouse gas (GHG) emissions. The findings indicate that the N-R HES is the most promising energy solution for the maritime industry, offering significant reductions in GHG emissions while enhancing economic performance. Vergara et al. [15] explored the overall characteristics of a FastShip (250 MW with 5 gas-turbines) equipped with a nuclear power plant, examining its advantages, limitations, unresolved challenges, and potential opportunities for high-speed, nuclear-powered cargo vessels. The research resulted that collisions, groundings, or sinking are potential risks for any vessel, though modern safety measures make such incidents highly preventable. In the event of any of these emergencies, nuclear reactors must be capable of a safe shutdown, with the likelihood of radioactive release minimized as much as possible. Both the plant layout and the ship's structural design should be optimized to protect the reactor from damage. In the event of a sinking, the reactor would need to equalize pressure to prevent a catastrophic collapse, while carbon-based fuel elements should release radiation slowly enough to keep environmental exposure near background levels. Overall, with proper design practices and operational procedures, nuclear power can be considered a safe energy technology. The gas turbine-modular helium reactor (GT-MHR) is particularly notable for its high safety standards among reactor designs. Beliavskii et al. [16] outlines the methodology used to evaluate the operational fuel lifetime of the RITM-200, a small modular pressurized water reactor (PWR) with a thermal output of 200 MW. The findings indicate that the optimal fuel composition is (232Th + 233U)O2, combined with an increased fuel diameter of 7.9 mm. This configuration significantly enhances performance, extending the fuel lifetime by 78% and increasing burnup by 50% compared to the baseline design specifications. Additionally, the integrated design of the RITM-200 improves the manufacturability of the reactor pressure vessel, reducing production costs and time by incorporating the primary equipment within the vessel of the steam generation unit. Hoque et al. [17] proposed and analyzed a small modular reactor targeted marine vessel and noted that the marine propulsion sector has explored a broader range of reactor concepts compared to the power generation industry, with various assemblies and research laboratories driving this innovation. The lessons learned from these marine applications can provide valuable insights for advancing land-based reactor technologies. Additionally, the incorporation of advanced safety features in Small Modular Reactors (SMRs) enhances their resilience, offering robust protection for both public safety and investor interests. Hirdaris et al. [18] reviewed historical and recent developments in marine nuclear propulsion and, as a demonstration, presents technical considerations for designing a Suezmax tanker powered by the Gen4 Energy 70 MW Small Modular Reactor (SMR). It highlights that comprehending the technical risks and consequences of integrating advanced nuclear technology is an essential initial step in the long-term effort to develop the required knowledge and expertise in this domain.

Nuclear propulsion systems (NPSs) have proven highly effective, particularly in military vessels and icebreakers. Despite this success, nuclear systems have not yet achieved a prominent role in the broader energy market. However, small nuclear power plants (NPPs), a subset of land-based reactors, offer considerable advantages over conventional energy production methods, especially in remote and challenging locations. Nuclear reactors typically use fuels such as uranium, plutonium, thorium, or mixed oxide, which combines uranium and plutonium.

Although significant research has been conducted on the development of land-based nuclear power plants and certain marine vessel applications, there has been a lack of recent and comprehensive studies on the use of nuclear energy as a marine fuel, especially for cargo ships. This paper seeks to fill the existing gap in the literature by assessing the viability of nuclear energy as an alternative propulsion system, with the potential to support zero-carbon objectives in commercial maritime shipping. The analysis informed by a literature review and maritime sector reports, identifies the key advantages and disadvantages of nuclear power. To further enrich the study, the analysis of reactor type, propulsion system and regulation framework are also carried out. The paper presents a detailed analysis of the impact of various factors, providing a comprehensive understanding of both internal and external considerations involved in the adoption of nuclear fuel for commercial shipping. These factors are thoroughly examined and discussed throughout the study.

2. Nuclear Powered Vessel from Literature

2.1 Propulsion System

Several nuclear-powered propulsion options are emerging as potential candidates for the future of merchant ship propulsion [19]. Beyond the conventional pressurized water reactors, other possibilities include high-temperature reactors paired with closed-cycle helium gas turbines or open-cycle gas turbines [20]. Additionally, boiling water reactors are under consideration, and, in the future, nuclear batteries may also be feasible for maritime applications if successfully adapted for marine use [21].

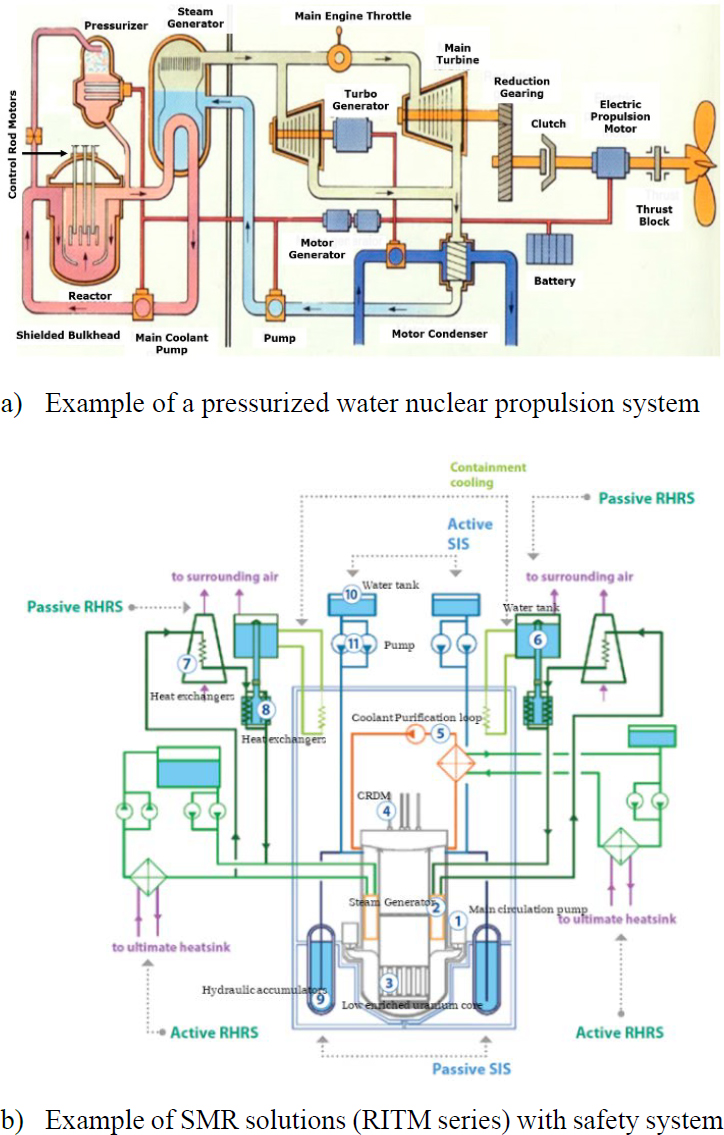

Nuclear power systems are known for their high reliability, economic benefits, and environmental sustainability. The pressurized water reactor (PWR) consists of two separate loops, both requiring stringent safety measures. The primary loop's coolant system transfers heat generated by core of the reactor to the secondary part of the steam generator, producing saturated steam. The secondary loop serves two main functions: first, it completes a closed thermodynamic cycle by directing the steam to the turbine and associated mechanical equipment, thereby converting thermal energy into mechanical energy and electricity; second, it helps maintain reactor safety by removing heat from the fission process.

The secondary circuit of a nuclear power plant consists of various essential power systems and equipment, including feedwater and steam discharge systems, control valves, and safety valves, all contributing to effective heat dissipation (Figure 1). The process begins when superheated steam, produced by the steam generator, enters the main steam turbine under high pressure, performing mechanical work. Subsequently, the exhaust steam is directed to the condenser, where it is cooled and collected in the hot well. In emergency scenarios, a significant volume of steam is directly routed to the condenser. The condensed steam is then pumped, pressurized, and transferred to the water supply system before being returned to the steam generator. This cycle ensures the efficient thermal and fluid flow processes within the secondary circuit. The condenser acts as the cold end, effectively removing heat from the low-temperature exhaust steam in the circulation system.

2.2 Reactor Types

Marine reactors, such as those used in ships and submarines, are smaller in size compared to land-based power reactors. This compact design allows for a quicker response to fluctuations in power demand, requiring an advanced control system to manage these dynamic conditions effectively. Despite the rapid-response capabilities of nuclear propulsion systems, it can still be designed to handle the complex maneuvers required for berthing and navigating in confined spaces. In practice, a nuclear-powered ship can autonomously approach and position itself near the berth, with a tugboat only assisting during the final stages of docking.

The core components of a nuclear reactor include the fuel, control rods, and the moderator. Control rods are essential for regulating the nuclear chain reaction. These rods, composed of materials with high thermal neutron absorption capabilities, such as cadmium and boron, function as adjustable "poisons" to regulate and control the reactivity levels within the reactor. The primary functions of control rods are: i) enabling planned changes in reactor operations, such as start-up and shut-down, ii) adjusting to variations in operating conditions, including shifts in fuel composition and poison levels, and, iii) providing a mechanism for emergency shutdown when necessary.

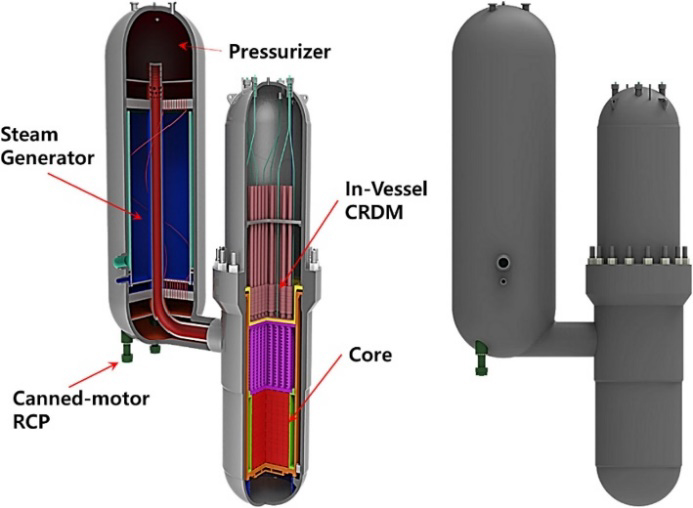

Small and Medium-sized Reactors (SMRs) represent a new generation of nuclear reactors that are designed to be modular, scalable, and safer than traditional large reactors. According to the International Atomic Energy Agency (IAEA), SMRs are classified based on their electrical power output, with small reactors generating up to 300 MW and medium-sized reactors producing between 300 and 700 MW [24]. Like all nuclear reactors, SMRs generate heat by initiating a chain reaction in fissile material, which is then transferred to a power conversion system via a coolant to produce electricity. SMRs are gaining increasing global attention due to their modular design, which simplifies construction, reduces costs, and accelerates deployment. Additionally, they incorporate advanced safety features such as passive safety systems and multiple protective barriers to prevent the release of fission products, even under extreme conditions [25]. These enhanced safety mechanisms enable a reduced Emergency Planning Zone (EPZ), confined to the site boundary, thereby improving emergency response readiness.

In South Korea, Korea Electric Power Corporation (KEPCO) is developing the BANDI-60S, a Small Modular Reactor designed for Floating Nuclear Power Plants (FNPPs) (Figure 2). This two-loop Pressurized Water Reactor (PWR) has a thermal output of 200 MWt and an electrical output of 60 MWe, intended to provide reliable energy to remote locations, such as islands and offshore platforms. The BANDI-60S features a block-type configuration, which enhances safety by minimizing the risks associated with large coolant pipe failures. In collaboration with Daewoo Shipbuilding & Marine Engineering (DSME), KEPCO is targeting niche markets with this reactor, which boasts a 60-year operational lifespan, a fuel cycle of 48–60 months, and a burnup rate of 35 GWd/t, ensuring a sustainable energy solution for specialized applications.

One key operational consideration for reactor fuel specifications is the fuel burn-up rate, which measures the energy output per unit mass of fuel. This rate directly correlates with the fuel’s enrichment level and influences the interval between refueling cycles. Additionally, the energy generated from a fuel rod assembly depends on both the reactor type and the specific operational strategies set by the reactor operator.

2.3 Safety Concerned of Nuclear-Powered Cargo Ship

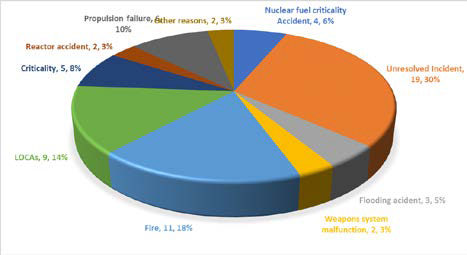

Figure 3 illustrates the occurrence of 63 incidents involving nuclear-powered ship, highlighting the inherent risks associated with such ships.

Significant incidents have highlighted critical safety concerns in the maritime nuclear sector. These include [28] the tragic 2000 Kursk submarine disaster, which resulted in the loss of all 118 crew members, and the 2003 collision between the USS Hartford and USS New Orleans, which caused substantial damage but did not lead to a radiation leak. In 2005, the grounding of the USS San Francisco resulted in one fatality, while the 2011 Fukushima Daiichi disaster had profound implications for nuclear safety regulations, affecting both terrestrial and maritime operations. In 2012, a fire aboard the USS Miami caused extensive damage, though no radiation was released. More recently, the 2019 fire on the Russian submarine Losharik claimed the lives of 14 crew members, further emphasizing concerns about the safety of aging nuclear-powered fleets.

As for safe operation of nuclear-powered cargo ship, the primary safety objectives have been established through:

- ∘ Safeguarding people and the environment from significant risks associated with both intentional and accidental releases of radioactive materials and ionizing radiation, in both port and at sea.

- ∘ Ensuring the overall safety of the ship by addressing all potential hazards, not limited to those related to nuclear propulsion.

- ∘ Maintaining the safety of the interactions between the nuclear propulsion system, the ship, its cargo, and the surrounding operating environment.

Thus, it is essential to define radiation hazard zones within the ship, similar to fire zones and watertight compartments. Typically, three areas are designated:

- ① Limited access area, encompassing the reactor containment shell, which houses the reactor, control rods, flux sensing equipment, primary piping loops, and pumps.

- ② The intermittent access area encompasses components such as purifiers, ion exchangers, waste collection systems, after-cooling systems, and the secondary side of heat exchangers. These elements are integral to the overall functionality and maintenance of the system.

- ③ General access area, comprising all remaining spaces within the ship.

These areas help manage and mitigate radiation exposure risks onboard.

The rising cost of oil and the growing demand for larger, faster merchant ships have significantly renewed interest in the application of nuclear steam supply systems for both commercial vessels and icebreakers. However, a comprehensive risk assessment should be carried out for the design, construction, operation, and decommissioning of the nuclear-powered vessel to evaluate the potential hazards associated with the nuclear plant and its systems, focusing on their impact on both the crew and the surrounding environment [29]. A critical focus is the evaluation of loss-of-coolant accidents (LOCA) in these nuclear-powered ships, along with the development of engineering design features to mitigate the risk of radioactive releases following such incidents. Additionally, a comprehensive assessment of other potential reactor and system-related accidents, under both static and dynamic conditions, is essential for ensuring safety and reliability.

2.4 Regulations and Framework

Governments, particularly those along established trade routes, will play a pivotal role in the adoption of nuclear-powered maritime vessels. However, if nuclear propulsion extends to broader sectors, such as cruise ships or private yachts, the involvement of a larger coalition of countries will be essential. While political engagement in this domain may seem to be primarily technical focusing on safety, environmental impact, and operational protocols the regulatory approaches could differ significantly, reflecting a variety of political, electoral, or commercial interests. Two primary regulatory frameworks are anticipated: a prescriptive approach, which imposes specific requirements, and a goal-based safety model, which emphasizes achieving particular safety outcomes.

The current international maritime legal framework is largely shaped by conventions from the IMO and the International Labour Organization (ILO). The IMO has established Emission Control Areas (ECAs) with stringent limits on sulfur oxide (SOx) and nitrogen oxide (NOx) emissions [30]. The primary international frameworks governing the operation of civilian nuclear-powered vessels include:

- ∘ The United Nations Convention on the Law of the Sea (UNCLOS)

- ∘ The International Maritime Organization (IMO) Convention for the Safety of Life at Sea (SOLAS)

- ∘ IMO instruments such as the Convention on the Liability of Operators of Nuclear Ships and the Code of Safety for Nuclear Merchant Ships

- ∘ Relevant countries legislative provisions.

In 1981, the IMO adopted Resolution A.491 (XII), known as the code of safety for nuclear merchant ships, although it has yet to be implemented. Presently, there are no standardized regulations governing the design, operation, or development of nuclear-powered merchant vessels. While the sea transport of radioactive materials and nuclear waste from power plants has occurred for nearly 50 years [31], the international legal framework governing these shipments remains fragmented and inconsistent [32]. Furthermore, exclusive economic zones (EEZs) obligate coastal states to enforce pollution regulations, while classification societies continue to serve as the primary technical authority within the civilian shipping industry.

In 1962, the IMO introduced the Convention on the Liability of Operators of Nuclear Ships, commonly referred to as the Brussels Convention. This initiative aimed to create a standardized legal framework governing the responsibilities of nuclear ship operators. However, the convention was never ratified and, consequently, did not come into effect. Despite this, many of its provisions align closely with other international nuclear agreements and adhere to fundamental principles of civil law concerning liability and compensation for damages.

Chapter VIII of the SOLAS (Safety of life at sea) convention includes twelve specific regulations governing the operation of nuclear-powered vessels. These regulations apply to all nuclear-powered ships, excluding military vessels (Rule 1), and require full compliance with both the general SOLAS provisions and the additional requirements outlined in IMO Resolution A.491(XII) (Rule 2).

Legislation establishes a framework to safeguard the rights of all stakeholders involved in the process. However, influencing public opinion cannot be achieved solely through regulatory measures; it requires open and transparent dialogue. Building trust in shipping technologies necessitates collaboration among the scientific community, governments, and environmental advocates to demonstrate their reliability and address concerns within local communities.

3. Experiments and Real-World Applications

Before exploring detailed concepts for the application of nuclear energy in shipping, it is crucial to review past experiences, highlighting key successes, challenges, and setbacks. This study examines four nuclear-powered vessels designed for general navigation: the NS Savannah, NS Otto Hahn, NS Mutsu, and NS Sevmorput. Icebreakers are excluded from the analysis due to their specialized functions, which make them less applicable to the typical operations of merchant vessels.

The use of PWRs in naval and icebreakers applications has demonstrated exceptional system reliability, provided that engineering and control systems are meticulously designed. These power plants, including refueling operations, have consistently achieved reliability rates above 95%, as evidenced by naval operations. This high level of reliability is further reinforced by early experiences with nuclear-powered merchant vessels, such as the Savannah and Otto Hahn. With most maritime nuclear experience involving PWR systems, there is a substantial knowledge base that can be leveraged to apply nuclear propulsion to cargo shipping.

Public acceptance is a vital factor in the success of SMR-powered vessels, requiring comprehensive environmental impact assessments (EIAs) and transparent communication to build trust and ensure alignment with global sustainability objectives. Although challenges remain, these issues also present opportunities for innovation and international cooperation. By addressing regulatory barriers and public concerns through coordinated policies and actions, SMR propulsion has the potential to become a cornerstone of a more sustainable, efficient, and technologically advanced maritime industry. The successful deployment of SMRs could play a pivotal role in the global energy transition, driving the move toward low-carbon shipping and supporting the development of a greener maritime sector.

4. Discussions

4.1. Pressurized Water Reactors

PWRs have become the effective design for maritime nuclear propulsion due to their simplicity, safety, and compactness, making them the preferred choice for nuclear-powered vessels. These features are particularly beneficial for cargo ships, as they optimize cargo space. Modern PWR-based nuclear plants now meet significantly higher safety standards than their earlier counterparts, with lower costs compared to designs from the 1990s. This progress has largely been driven by the integration of passive safety systems and the simplification of plant design, with additional reductions in complexity possible for naval reactors, which are in continuous operation at sea. However, one major challenge is the need for reinforced piping and heavy pressure vessels to maintain water in a liquid state at high pressure and temperature, which significantly raises construction costs. Furthermore, PWRs typically require refueling certain time, necessitating reactor shutdowns for several weeks to complete the refueling process, interrupting continuous operation. Another concern is the potential contamination of the coolant with boric acid, which, although the primary coolant cycle remains uncontaminated, can leach into the system. This acid is corrosive to carbon steel, and its presence may lead to the circulation of radioactive products, potentially damaging the reactor and limiting its operational lifespan due to radiation exposure.

Despite these advancements, several challenges remain, including high capital costs, concerns over nuclear proliferation, and stringent regulatory standards. While nuclear facilities are subject to performance-based regulations, merchant vessels must comply with prescriptive standards, which can increase operational complexity. Nuclear-powered ships are also subject to comprehensive inspections by nuclear authorities, necessitating specialized expertise and infrastructure, which drives up costs, particularly for a limited fleet. Ownership and management of nuclear waste further complicate the process. Public concern about nuclear energy, fueled by disasters like Chernobyl and Fukushima, has led many nations to abandon nuclear power, resulting in entry restrictions for nuclear-powered merchant vessels such as the NS Otto Hahn and NS Sevmorput at various ports.

The reactor compartment's structural design aboard ships must be meticulously engineered to withstand the dynamic stresses of seaway conditions, such as slamming, whipping, and vibrations. Ensuring effective strain distribution and accommodating stress relaxation across the structure is crucial to minimizing the risks of fatigue and brittle fracture. While land-based reactors are designed to withstand direct impacts, such as from aircraft, adapting these safety measures for marine environments requires special attention. Unlike land-based installations, which are fixed to the ground, ships operate in water, a medium unable to resist shear forces. Therefore, maintaining the ship's intact and damage stability is critical to ensuring the safe operation of a marine nuclear reactor.

4.2. Nuclear Fuel Cycle

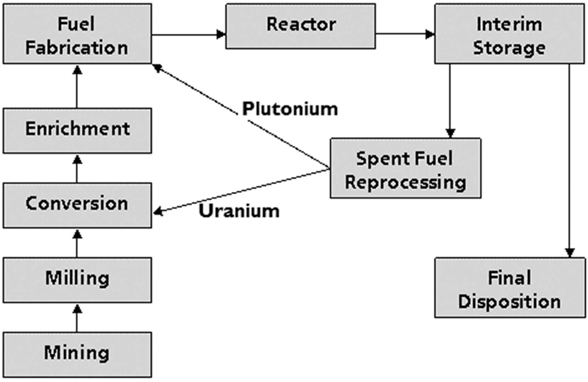

The nuclear fuel cycle starts with the extraction of uranium, which is obtained through a variety of mining techniques, such as open-pit mining, underground mining, and in-situ leaching, all of which produce uranium ore. This ore is then processed to obtain uranium oxide concentrate. However, this concentrate cannot be directly used in most reactors, as only a small percentage (less than 1%) of natural uranium is fissile. To address this, the concentrate undergoes an enrichment process, which increases the concentration of the fissile uranium isotope.

The fuel cycle progresses through several key stages: conversion, enrichment, fuel fabrication, and utilization in reactors. After the fuel is used in the reactor, the cycle continues with the storage of spent fuel, followed by either reprocessing or disposal. Reprocessing allows the nuclear fuel cycle to operate as a closed loop, enabling the recovery and reuse of fissile materials.

4.3. Life Cycle Cost

In conventionally powered cargo ships, operational costs are spread out over the lifespan of the ship, whereas nuclear-powered ships incur a significant portion of their costs upfront during the initial purchase. By the third quarter of 2022, the uranium spot price had risen to approximately USD $52.00/lb U3O8, reflecting a notable increase from around USD $32.00/lb during the same period in 2021 [33]. This represents a growth of roughly 42% since 2021 and an overall rise exceeding 64% over the past two years. This sustained upward trend has revitalized the uranium production sector, prompting several major producers to consider resuming operations that were previously halted and placed under care and maintenance due to prolonged low spot prices.

The production of nuclear fuel is a well-established technology that has undergone significant advancements over time, driven by the adoption of automation and digitization. These improvements have resulted in reduced operational waste, enhanced worker radiation protection, and notable advancements in economic efficiency. For instance, fuel cycle durations have been extended from 12 to 18 months or even 24 months, achieving higher burnup rates. Reliability has also been improved through measures such as reducing fuel failures, developing advanced fuel designs to prevent assembly bowing, enhancing seismic performance, and incorporating innovations like doped fuel, liner, and duplex cladding for better corrosion resistance.

Furthermore, sustainability has been enhanced by enabling the recycling and multi-recycling of nuclear fuel for both light water reactors (LWRs) and fast reactors. Currently, global nuclear fuel fabrication capacities are sufficient to meet the projected demand for nuclear power, supporting both existing and future energy needs.

Given current fuel prices, nuclear propulsion becomes cost-effective mainly when assessed on a total life-cycle cost basis. However, with the maritime industry transitioning toward distillate fuels and the potential introduction of carbon taxes, the economic appeal of nuclear power is increasingly evident. This distinct cost structure of nuclear-powered ships suggests that the traditional methods for determining chartering rates would need substantial revision to accommodate the unique economic model of nuclear propulsion.

4.4. Public Acceptance

The acceptance of nuclear-powered vessels within a nation's territorial waters, from both regulatory and public perspectives, remains a subject of ongoing interest. While nuclear-powered vessels have historically operated internationally, establishing a precedent for global trade decades ago, their potential for integration into today’s merchant fleet warrants further consideration. For instance, the Russian icebreaker NS 50 years of victory, operated by several adventure cruise companies, currently offers Arctic expeditions, accommodating up to 128 passengers. Departing from Murmansk in the summer months, this vessel illustrates that at least one country permits nuclear-powered ships in its waters, and that passengers are willing to embark on such vessels. These cruise companies are transparent about the vessel’s nuclear propulsion, openly highlighting its power source in their marketing materials to ensure prospective passengers are well-informed.

5. Lessons Learned

From an engineering perspective, the development of a nuclear propulsion system for cargo ships is technically feasible, particularly with the wealth of design experience already accumulated. The design process should adhere to a safety-case framework, integrating considerations from nuclear, mechanical, electrical, and naval architecture disciplines, with an emphasis on ensuring the safety of the nuclear plant above all else. A successful design must involve early evaluations of potential failures across both ship systems and nuclear plant components, as issues in one area could affect the other.

The mentioned research in this paper has shown that PWR technology is the most commonly applied nuclear propulsion system at sea, having demonstrated remarkable reliability over more than 55 years of maritime use. While other nuclear technologies are emerging with potential for marine applications, the integration of nuclear systems into ships requires a fundamental redesign of the vessel’s layout to optimize reactor performance. Critical design factors include the reactor’s placement and the reinforcement of structural protections against impacts and vibrations, with particular focus on absorbing and distributing impact forces. Studies of PWR use in merchant vessels reveal no significant technological barriers to the construction and operation of nuclear-powered merchant ships.

For initial applications in merchant shipping, a conventional PWR combined with a steam turbine propulsion system would likely be chosen. This configuration could drive the ship's main propulsion through a locked-train, double-reduction gearbox, with steam diverted to power turbo-generators. Alternatively, the main steam turbine could also serve as a turbo-generator for an electrically driven vessel, a promising option for ships with high non-propulsion power requirements, such as those for hotel services.

Key takeaways from early nuclear propulsion experiments indicate that while these technologies offered a promising path to zero greenhouse gas emissions, they were constrained by the limitations of their time. Even if nuclear propulsion had continued in commercial fleets, the high operational costs would have made these ships economically unviable, resulting in their phase-out and relegation to niche uses without significantly influencing the mainstream development of maritime technology.

The primary insights gained from these experiments include:

- ∘ Nuclear-powered ships are associated with significant life-cycle costs, which remain challenging to estimate with precision.

- ∘ Experimental vessels were typically owned by state-run companies, with the responsibility for both costs and benefits lying with the nations overseeing them throughout their life cycle. Unlike modern shipping practices involving "flags of convenience," these vessels remained under the control of their home countries.

- ∘ Merchant vessels often do not meet stringent vibration standards, so careful attention to vibration characteristics within machinery spaces is vital for nuclear applications. Steam-driven prime movers, when properly installed and maintained, produce minimal vibration and can be effectively mounted to isolate the reactor plant and primary circuit from vibrations caused by the propeller and sea conditions. Insights gained from deploying nuclear reactors on aircraft carriers and other surface vessels provide useful guidance for addressing vibration challenges in merchant ships.

Valuable insights were gained in marine safety and nuclear technology, such as the development and testing of ship reactor control rod drives. However, these lessons are less applicable in today’s shipping practices, which have evolved with modern technologies and organizational structures.

6. Conclusions

Nuclear power has a long history in marine propulsion, with applications in both military and commercial sectors. A critical takeaway from nuclear propulsion is that the successful integration of nuclear energy in shipping hinges on the establishment of a comprehensive regulatory framework. The transnational and mobile nature of maritime operations, combined with a fragmented and evolving regulatory landscape, introduces significant ethical challenges to the reintroduction of nuclear propulsion. These complexities currently pose major barriers to the widespread adoption of nuclear technology within the shipping industry.

The majority of maritime nuclear experience involves PWR systems. However, due to safety concerns related to reinforced piping, heavy pressure vessels, robust reactor design, radiation protection, and the containment of radioactive materials in PWRs, small modular reactors (SMRs) such as SMART, BANDI-60, SMR-160/300, and RITM-200 have been developed to address the evolving economic, safety, and environmental challenges faced by the nuclear industry. Public perception remains a significant challenge, though it is believed that these concerns can be addressed. The actions and policies of port and flag states will be pivotal in determining the future integration of nuclear propulsion in the maritime industry. However, some nations, and by extension their port states, already permit nuclear-powered vessels to enter their ports, signaling a degree of acceptance for this technology.

Key insights derived from the research questions, literature review, and lessons learned include the following conclusions:

- ① The construction of nuclear-powered merchant vessels for ocean freight is unlikely unless life-cycle costs and infrastructure support are substantially optimized compared to conventional vessels.

- ② The development of nuclear enrichment process and system are essential for application of marine cargo nuclear powered ship.

- ③ Incorporating nuclear technology into a ship’s design requires significant modifications to the traditional layout to create an environment conducive to the reactor’s operation. A major consideration is the precise placement of the reactor, along with robust protection against collisions and vibrations. The surrounding structure should be engineered to absorb and distribute impact forces, minimizing the risk to the reactor.

- ④ Policy of import and export uranium is importance to process nuclear powered ship.

Port and coastal state acceptance remains a fundamental challenge. For any nuclear-powered merchant vessel, a designated flag state, home port, and service base must be established and maintained throughout its operational lifespan. Consensus on the rights of flag and port states must be reached before further trials can proceed.

Acknowledgments

This research was supported by Korea Evaluation Institute of Industrial Technology (KEIT) grant funded by the Ministry of Trade, Industry and Energy (MOTIE) (RS-2023-00285272; RS-2024-00420993 and RS-2024-00434535).

Author Contributions

Conceptualization, P.A. Duong; Methodology, P.A Duong and H.K. Kang; Formal Analysis, P.A. Duong; Investigation, P.A. Duong; Resources, J. Jung; Data Curation H.K. Kang; Writing-Original Draft Preparation, P.A. Duong; Writing-Review & Editing, P.A. Duong; Visualization, H.K. Kang; Supervision, H.K. Kang; Project Administration, P.A. Duong; Funding Acquisition, H.K. Kang.

References

-

P. A. Duong, B. Ryu, C. Kim, J. Lee, and H. Kang, “Energy and exergy analysis of an ammonia fuel cell integrated system for marine vessels,” Energies, vol. 15, no. 9, 3331, 2022.

[https://doi.org/10.3390/en15093331]

-

P. A. Duong, B. Ryu, J. Jung, and H. Kang, “Thermal eval-uation of a novel integrated system based on solid oxide fuel cells and combined heat and power production using ammonia as fuel,” Applied Sciences, vol. 12, no. 12, 6287, 2022.

[https://doi.org/10.3390/app12126287]

-

P. A. Duong, B. R. Ryu, M. K. Song, H. Van Nguyen, and D. Nam, and H. K. Kang, “Safety assessment of the ammo-nia bunkering process in the maritime sector : A review,” vol. 16, no. 10, 4019, 2023.

[https://doi.org/10.3390/en16104019]

-

H. Xing, C. Stuart, S. Spence, and H. Chen, “Alternative fuel options for low carbon maritime transportation: Pathways to 2050,” Journal of Cleaner Production, vol. 297, p. 126651, 2021.

[https://doi.org/10.1016/j.jclepro.2021.126651]

- Singapore Shipping Association, A guide for bunkering Industry - Moving towards IMO 2020 sulfur limit, 2020.

- T. I. M. Organization, “Resolution MPEC.328(76),” IMO, vol. MPEC 76/15, no. 1, pp. 37–72, 2021.

- International Maritime Organization, Adoption of the Initial IMO Strategy on Reduction of GHG Emissions from Ships, vol. 10, 2018.

-

J. Hansson, S. Brynolf, E. Fridell, and M. Lehtveer, “The potential role of ammonia as marine fuel-based on energy systems modeling and multi-criteria decision analysis,” Sustainability, vol. 12, no. 8, 3265, 2020.

[https://doi.org/10.3390/su12083265]

-

M. S. Eide, C. Chryssakis, and Ø. Endresen, “CO2 abatement potential towards 2050 for shipping, including alternative fuels,” Carbon Management, vol. 4, no. 3, pp. 275-289, 2014.

[https://doi.org/10.4155/cmt.13.27]

-

B. W. Brook and C. J. A. Bradshaw, “Key role for nuclear energy in global biodiversity conservation,” Conservation Biology, vol. 29, no. 3, pp. 702–712, 2015.

[https://doi.org/10.1111/cobi.12433]

-

J. Vergara, C. McKesson, and M. Walczak, “Sustainable energy for the marine sector,” Energy Policy, vol. 49, pp. 333-345, 2012.

[https://doi.org/10.1016/j.enpol.2012.06.026]

- J. Gravina, J. I. R. Blake, A. Shenoi, S. Turnock, and S. Hirdaris, “Concepts for a modular nuclear powered containership,” 7th International Conference on Ships and Shipping Research, 2013.

-

J. S. Carlton, R. Smart, and V. Jenkins, “The nuclear propulsion of merchant ships: Aspects of engineering, science and technology,” Journal of Marine Engineering & Technology, vol. 10, no. 2, pp. 47-59, 2014.

[https://doi.org/10.1080/20464177.2011.11020247]

-

H. A. Gabbar, M. I. Adham, and M. R. Abdussami, “Analysis of nuclear-renewable hybrid energy system for marine ships,” Energy Reports, vol. 7, pp. 2398-2417, 2021.

[https://doi.org/10.1016/j.egyr.2021.04.030]

-

J. A. Vergara and C. B. McKesson, “Marine technology nuclear propulsion in high-performance cargo vessels,” Marine Technology and SNAME News, vol. 39, no. 01, pp. 1-11, 2002.

[https://doi.org/10.5957/mt1.2002.39.1.1]

-

S. Beliavskii, N. Anikin, S. Alhassan, S. Kudeev, and V. Nesterov, “Effect of fuel nuclide composition on the fuel lifetime of the RITM-200 reactor unit,” Annals of Nuclear Energy, vol. 173, 109105, 2022.

[https://doi.org/10.1016/j.anucene.2022.109105]

-

M. Hoque, A. Z. M. Salauddin, and M. R. H. Khondoker, “Design and comparative analysis of small modular reactors for nuclear marine propulsion of a ship,” World Journal of Nuclear Science and Technology, vol. 08, no. 03, pp. 136-145, 2018.

[https://doi.org/10.4236/wjnst.2018.83012]

-

S. E. Hirdaris, Y. F. Cheng, P. Shallcross, et al., “Considerations on the potential use of Nuclear Small Modular Reactor (SMR) technology for merchant marine propulsion,” Ocean Engineering, vol. 79, pp. 101-130, 2014.

[https://doi.org/10.1016/j.oceaneng.2013.10.015]

- T. Breivik, et al., Future Ship powering options: Exploring alternative methods of ship propulsion, vol. 2, July, 2013.

-

C. F. McDonald, “Helium turbomachinery operating experience from gas turbine power plants and test facilities,” Applied Thermal Engineering, vol. 44, pp. 108-142, 2012.

[https://doi.org/10.1016/j.applthermaleng.2012.02.041]

- International Atomic Energy Agency (IAEA), Small Modular Reactors for Marine-based Nuclear Power Plant Technologies, Designs and Applications A supplement to: IAEA Advanced Reactors Information System (ARIS).

- A. M. Dunn, O. S. Hofmann, B. Waters, and E. Witchel, “Cloaking malware with the trusted platform module,” Proceedings of the 20th USENIX Security Symposium, pp. 395-410, 2011.

- ROSATOM, Rosatom SMR solutions RITM series, Https://Fnpp.Info/Files/Rosatom-Smr-Solutions-Brochure.Pdf, Accessed December 1, 2019.

-

B. D. Middleton and C. Mendez, “Integrating Safety, Operations, Security, and Safeguards into the design of small modular reactors,” ASME 2014 Small Modular Reactors Symposium, SMR 2014, pp. 1–54, 2014.

[https://doi.org/10.1115/SMR2014-3336]

-

H. O. Kang, B. J. Lee, and S. G. Lim, “Light water SMR development status in Korea,” Nuclear Engineering and Design, vol. 419, 112966, 2024.

[https://doi.org/10.1016/j.nucengdes.2024.112966]

-

S. M. Dmitriev, A. V. Kurachenkov, and V. V. Petrunin, “Scientific-technical and economic aspects for development of innovative reactor plants for small and medium nuclear power plants,” Journal of Physics: Conference Series, vol. 1683, no. 4, 2020.

[https://doi.org/10.1088/1742-6596/1683/4/042032]

- P. L. Ølgaard, Accidents in Nuclear Ships, 1996.

- P. L. Ølgaard, Accidents in Nuclear Ships, December, 1996. Technical University of Denmark.

- American Bureau of Shipping, Nuclear Power Systems for Marine and Offshore Applications, 2024.

- IMO, “Third IMO Greenhouse Gas Study 2014,” International. Maritime Organization, p. 327, 2015, London, UK.

-

C. Suykens, “Globalisation of the nuclear fuel cycle and maritime carriage of radioactive materials: Review of the le-gal regime,” International Journal of Maritime and Coastal Law, vol. 26, no. 3, pp. 385-411, 2011.

[https://doi.org/10.1163/157180811X582184]

-

R. Wang, “The precautionary principle in maritime affairs,” WMU Journal of Maritime Affairs, vol. 10, no. 2, pp. 143-165, 2011.

[https://doi.org/10.1007/s13437-011-0009-7]

- R. M. Grossi, Nuclear Technology Review 2023, IAEA, no. 67, 2023.