Analysis of sprinkler performance in a methanol pool fire using computational fluid dynamics

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

The pool fire process and sprinkler action against fires caused by liquid methanol leaks in the fuel preparation room of the ship was simulated using Pyrosim software to evaluate the reliability of sprinklers for fire suppression and extinguishment. The sprinkler performance was assessed by assuming spray velocity and droplet size as variables, and the simulation was performed by changing the spray height under the appropriate derived conditions. In this simulation, the highest fire suppression performance was observed with the smallest droplet size (100 μm) and lowest spray velocity (5 m/s) in the case of the assumed small scale fire. Under these conditions, complete fire extinguishment was achieved only at the lowest sprinkler installation height (3 m) when the temperature was less than the flash point of 11 ℃. In addition, a corresponding spray velocity was required to follow the set spray angle of the sprinkler. Based on these results, it can be concluded that the installation height, droplet size, injection angle, and corresponding spray velocity must be considered in the design of an appropriate sprinkler for suppressing small-scale methanol pool fires in a methanol-fueled ships.

Keywords:

Methanol, Computational Fluid Dynamics, Pyrosim, Sprinkler1. Introduction

To mitigate the growing concerns regarding air pollution, the International Energy Agency announced plans to reduce carbon dioxide emissions to net zero by 2050 and limit the global temperature rise to 1.5 ℃ [1]. Based on such reinforced regulations, research on use of renewable energy as primary fuels is being actively conducted. Among the alternative energy sources to replace conventional fossil fuels, methanol has attracted attention as the next-generation fuel. The number of ships that use methanol as fuel is increasing, including ships operated by large container shipping companies [2].

However, because methanol is highly flammable, the risk of fire is not negligible. For example, two methanol tank lorries collided and caused a fire inside the Shanxi Jinji highway tunnel in China on March 1, 2014, resulting in 31 casualties [3]. Additionally, an explosion occurred at the top of a methanol storage tank in India on December 30, which caused four human casualties [4]. In Korea, an explosion occurred inside a tank owing to the carelessness of a welder on May 25, 2004 killed two workers [5].

Research on identifying the methanol fire characteristics and preparing for such fire incidents should be conducted. Studies have been actively conducted using computer simulations that analyze the effect of different variables and obtain precise results. Li et al. investigated the fire characteristics of a methanol pool fire in an enclosed area using a fire dynamics simulator (FDS). They studied the relationship between fire growth, heat release rate, and pressure, focusing on changes in pressure [6]. Ilyas Sellami et al. also modeled and simulated the Boiling Liquid Expanding Vapor Explosion (BLEVE) fireball that occurred in the Algerian gas industry using an FDS; the simulation results were consistent with the experimental values [7]. Yvon Mouilleau et al. investigated the gas dispersion characteristics of ammonia and LNG using FDS and Phast, which is an analytical software program. They compared the analysis capabilities of the programs and investigated a method to increase the accuracy of the results obtained using FDS [8].

In a previous study that used simulation software programs other than FDS, Georgios Maragkos et al. compared the modeling of conventional Fire FOAM with the results of advanced Fire FOAM using methanol pool fire characteristics to present the benefits and shortcomings of the new analysis method. They found that advanced modeling is superior in quality and quantity but has a 20% increase in cost [9]. Adiga et al. assumed a gas fire in the form of a methanol pool using Fluent and found that ultrafine mist with a droplet size of 10 om or less showed the same behavior as the gas phase when a fire was extinguished using a sprinkler with droplets of ultrafine mist [10].

Although numerous studies have been conducted on the preparation required to address methanol fires, research on methanol fires on ships, in which receiving support from land is difficult, is insufficient. To ensure the stable protection of methanol fuel vessels, it is essential to conduct research on the performance of the sprinkler considering the workspace. With the increasing implementation of eco-friendly shipping, sprinklers, one of the primary alternatives to halogenated hydrocarbon digestion, have been widely used in various fields because of their advantages such as high efficiency, stability, low cost, sustainability, and environmental friendliness.

Previous studies have used various software to analyze the characteristics of fire. In this study, using Pyrosim software (ver.2022.3.1208), based on the FDS code, the sprinkler was operated in the event of a small scale methanol pool fire to analyze the flow of fire and to determine the appropriate sprinkler performance under assumed conditions. FDS is a software based on a large eddy simulation (LES) and an eddy dissipation concept combustion model, which is suitable for investigating the feasibility and reliability of sprinklers in methanol-fueled ships considering the risk of pool fires.

The paper is organized as follows. Section 2 presents the parameters of the simulation along with the necessary equations, grid, and boundary conditions. The sensitivity analysis for ensuring reliability is also detailed. Section 3 presents and discusses the results of simulating a small-scale pool fire. The fire suppression and fire extinguishing effect are analyzed according to sprinkler performance under various conditions. Section 4 concludes the paper with a summary of the study and conclusions drawn from the results.

2. Modeling and Parameter Setting

2.1 Mathematical Model

To analyze the instability of turbulent structures characterized by strong buoyancy through an LES turbulence model in an FDS, it is necessary to examine whether the simulation results are consistent with the actual fire-driven flow by selecting a suitable grid cell size to analyze the flow [11]. Therefore, in this study, grid sensitivity analysis was performed using the following equations.

| (1) |

| (2) |

| (3) |

| (4) |

where Q is the heat release rate, ∅ is the combustion efficiency factor, m is the mass combustion rate, ∆H is the calorific value of combustion, D* is the characteristic diameter of the fire source, ρ∞ is the air density, CP is the specific heat of air at constant pressure, T∞ is the ambient temperature, g is the gravitational acceleration, and δx is the grid size of the model. The optimal domain mesh size, D*⁄δx, was between four and 16 [11].

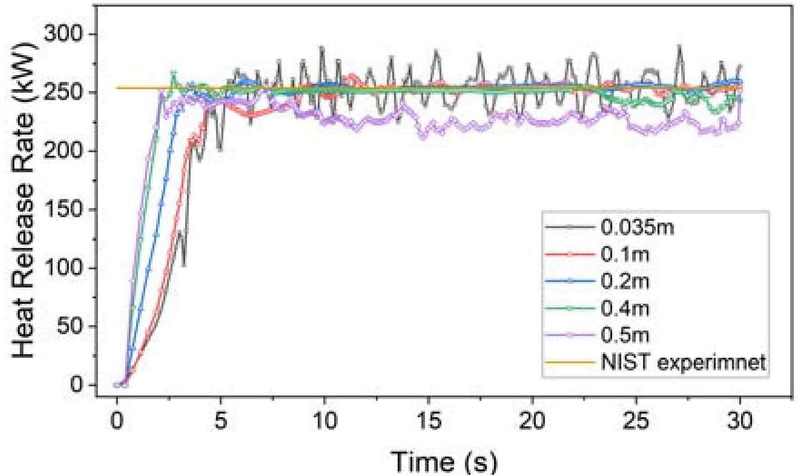

According to Equation (4), the finest grid size for analysis was , which was calculated to be 0.035 m. Figure 1 shows the result of deriving the most convergent value within the corresponding range when a methanol pool fire occurred at 254 kW in the simulation space. The heat release rate did not converge for grid cell sizes of 0.5 and 0.4 m but exhibited the highest convergence for 0.2 m. Therefore, the grid cell was assumed to be a square and of size 0.2 m in this study. Moreover, the boundary conditions were assumed such that all analysis spaces were closed to ensure an enclosed fuel preparation room.

In this study, the following conservation equations used in the FDS were adopted to analyze the fire-driven flow and particles of the sprinkler.

| (5) |

| (6) |

| (7) |

where ρ is the density, is the velocity vector, Yl is the mass fraction, Dl is diffusion coefficient, is mass production rate, p is the pressure, is the acceleration vector of gravity, is the external force vector, and is the viscous stress tensor. Equations (5), (6), and (7) are the mass, species, and momentum conservation equations, respectively [11][12].

Based on these conservation equations, the FDS defines the behavior of the spray droplets of the sprinkler as follows [11][13].

| (8) |

| (9) |

| (10) |

where md is the droplet mass, ud is the droplet velocity, u is the gas velocity, rd is the droplet radius, and CD is the drag coefficient. CD is determined by the Reynolds number (ReD) depending on the droplet diameter, as given in Equation (8). Therefore, the behavior of the spray droplets in the sprinkler is significantly affected by the ReD. These equations indicate that the spray fluid density, velocity, and droplet size are critical variables.

Additionally, the flow rate should be fixed when the spray velocity and droplet size are set as variables. The flow rate is defined as:

| (11) |

where k is the factor for flow rate and P is the operating pressure.

2.2 Simulation setup

This study considered a case in which a pool fire with a diameter of 1 m occurred owing to methanol leak in the fuel preparation room of a methanol-fueled ship. The source of the fire was assumed to be a single small-scale pool to verify the fire suppression effect of the sprinklers [14]. The applied heat release rate was 254 kW, which was adapted from a previous study conducted by the National Institute of Standards and Technology (NIST). In the experiment, a methanol pool fire burner with a diameter of 1 m and height of 1 cm was created, and the mass burning rate was measured using the decrease in the fuel in a 20 L methanol storage tank. Based on the measurements, the heat release rate was calculated [15]. In this study, the height of the pool fire was omitted using the function in the FDS.

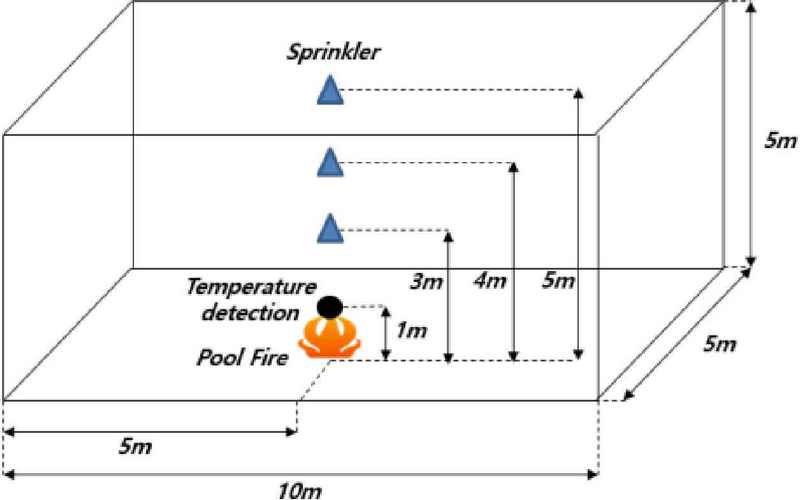

Figure 2 shows the simulation setup used in this study. The temperature around the fire was measured using a temperature sensor (T1) located 1 m from the fire source. Furthermore, the sprinkler was located at different distances (3, 4, and 5 m) depending on the scenario, to set the sprinkler height as a variable. Moreover, based on the size of the fuel preparation room, the simulation in which the methanol pool fire occurred in the center was set by assuming a width of approximately 10 m, length of 5 m, and height of 5 m.

According to NFPA704, the flammability of methanol is more prominent than its chemical stability and toxicity; therefore, fire safety measures, such as using non-spark tools, are required to handle this substance [16]. The International Code of Safety for Ships Using Gases or Other Low-Flashpoint Fuels (IGF code) requires sufficient sprinkler performance to handle fires related to fuels with low flash points, including methanol [17]. Therefore, the parameters of the sprinkler were assumed in this study, as listed in Table 1. The operating pressure in the simulation was set as 17 bar considering the maximum operating pressure (17.2 bar) of the sprinkler defined by the National Fire Protection Association 13 (NFPA13). The k-factor that determines the spray flow rate is defined as 40 L/(min·atm2) for a marine system; the same value was used in this study. Additionally, the sprinkler was activated after 10 s when the peak temperature was recorded during the fire, and the temperature of the working water was set to 10 ℃ below the flash point for extinguishment [18].

The methanol pool fires reignite when the temperature of the entire fire source area does not decrease below the flash point [19]. Therefore, sprinkler performance beyond that required for fire suppression is necessary to extinguish fires. This study attempted to derive the appropriate performance for complete fire extinguishment. The simulation condition aimed to reduce the temperature around the fire source to less than 11 ℃, which is the ignition point of methanol.

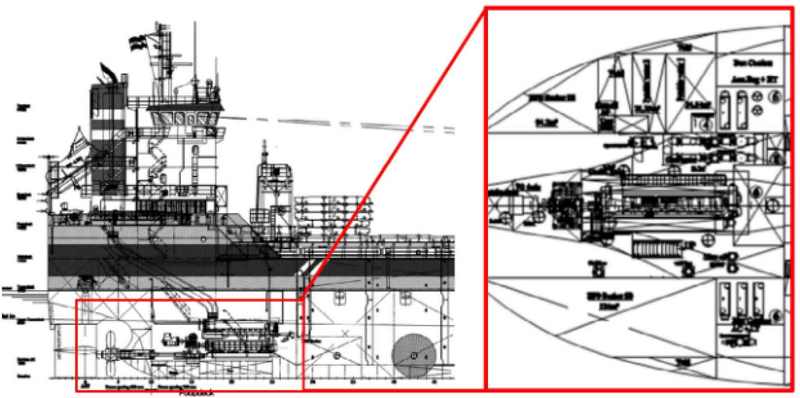

Figure 3 shows a methanol-fueled model ship from the Green Maritime Methanol Project [20]. The ship is an E-series container vessel operated by Wagenborg Shipping using marine gas oil. It features a 9L32C Wärtsilä engine that uses methanol as fuel; the fuel preparation room for fuel supply is as shown in Figure 3. A fuel preparation room is defined by class as any space containing vaporizers, pumps, and/or compressors for preparing fuel. Because methanol can be supplied to the fuel preparation room in a closed environment, pool fires may occur owing to leakage, making it necessary to install fire suppression systems.

To simulate the sprinkler performance, its spray velocity, droplet size, and height were set as variables. The spray velocity was assumed to be 5, 10, or 15 m/s to examine the changes within the sprinkler performance experimental range of 1–20 m/s [21]. For the droplet size, 100 μm, a criterion for fine atomization; 300 μm, a criterion for semi-fine atomization; and 1,000 μm, a criterion for semi-coarse atomization were assumed [22]. The spray height, which was expected to affect both the spray velocity and droplet size, was set to 3, 4, and 5 m. Using these variables, the temperature change around the fire source was observed over time.

3. Results and Discussion

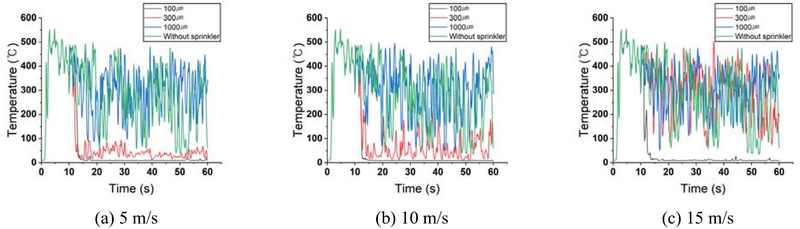

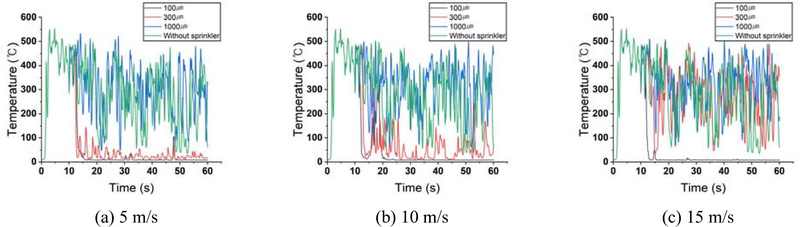

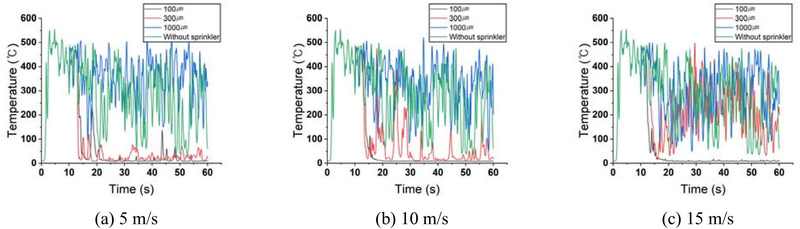

3.1 Droplet Size

Figures 4–6 show the temperature changes around the fire source according to the spray velocity and droplet size when the sprinkler was installed at heights of 3, 4, and 5 m. When the largest droplet size of 1,000 μm was injected at velocities of 5, 10, and 15 m/s from all the heights considered, the temperature change was similar to that observed in the case with no sprinkler. When a droplet size of 300 μm and velocities of 5 and 10 m/s were assumed, it was found that the fire was suppressed to less than 200 ℃ in the entire section. For the smallest droplet size of 100 μm, the temperature was less than 50 ℃ in all simulation results. This indicates that the fire suppression capability improved as the droplet size decreased under the assumed conditions.

3.2 Spray Velocity and Angle

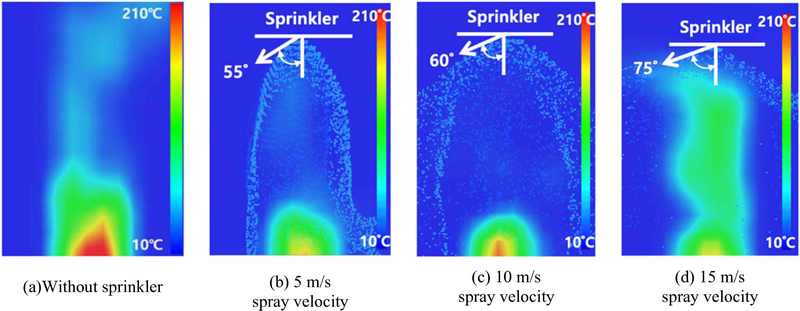

When the sprinkler installation height and droplet size were fixed at 3 m and 300 μm, there are a tendency that the temperature did not decrease relatively at some spray velocity. To clarify the reason for this observation, the cross-section of the temperature profile around the fire source at different heights and sizes were examined as shown in Figure 7 for different velocities.

Cross-section of fire temperature for different sprinkler spray velocities for a height of 3 m and a droplet size of 300 μm

Under the same conditions, when the spray velocity was highest (15 m/s), as shown in Figure 7(d), the spray angle of the sprinkler was approximately 75º and the cross-sectional area of the fire was large because the fire was less affected by sprinkler.

When the spray velocity was 10 m/s as shown in Figure 7(c), the cross-sectional area of the fire became relatively small at a spray angle of approximately 60º, but the temperature was high.

However, when the spray velocity was 5 m/s, both the cross-sectional area and the temperature of the fire decreased as the impact of the sprinkler increased at a spray angle of approximately 55º, as shown in Figure 7(b). This indicates that the spray velocity affects the spray angle. Under the assumed conditions, the fire suppression effect increased as the spray velocity decreased.

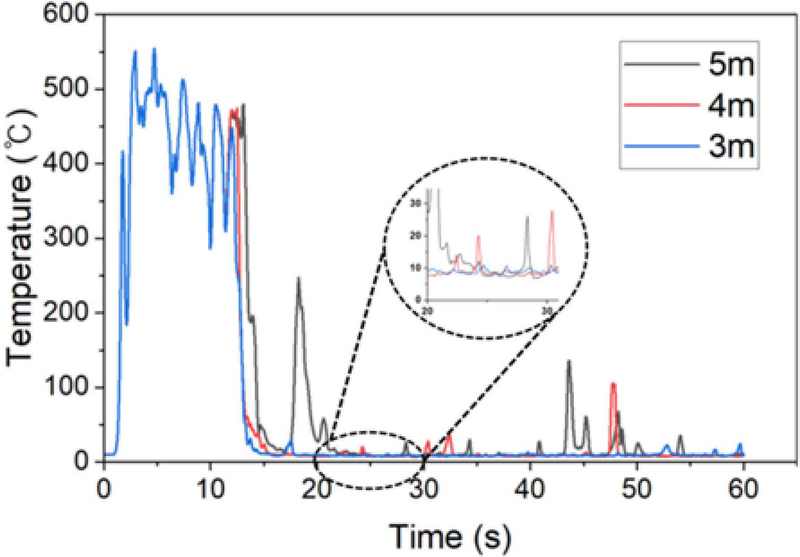

3.3 Spray height

In the previous section, 100 μm and 5 m/s were selected as the appropriate droplet size and spray velocity, respectively. However, because the effectiveness of fire suppression may vary depending on the height, the installation height should be simulated. Figure 8 shows the change in the temperature around the fire source over time for different sprinkler installation heights when the droplet size and the spray velocity were fixed at 100 μm and 5 m/s, respectively. When the sprinkler installation height was 4 or 5 m, the fire was extinguished as the temperature around the fire source dropped below the flash point, however it was reignited intermittently as the temperature exceeded approximately 20 ℃. When the sprinkler installation height was 3 m, the fire was extinguished as the temperature was maintained below a flash point of 11 ℃.

4. Conclusions

In this study, a small-scale pool fire that may occur during methanol supply in the fuel preparation room of a methanol-fueled ship was simulated, and sprinkler performance optimization for droplet size, spray velocity, and spray height was investigated.

When a small-scale methanol pool fire with a diameter of 1 m and a heat release rate of 254 kW occurred in the fuel preparation room, the sprinkler showed no fire suppression effect at spray droplet size of 1,000 μm; however, the fire temperature decreased to less than 200 ℃ at droplet size of 300 μm and less than 50 ℃ at 100 μm. This indicates that the fire-suppression effect increased as the droplet size decreased under the assumed conditions.

When the simulation was performed assuming spray velocities of 5, 10, and 15 m/s, the fire range appeared to increase with the spray velocity. This is attributed to the spray angle changing with spray velocity. The spray angles were measured as 75º, 60º, and 55º at spray velocities of 15, 10, and 5 m/s, respectively.

The sprinkler installation height was changed from 3 to 4 and 5 m after fixing the droplet size and spray velocity at 100 μm and 5 m/s, respectively. At 3 m, the pool fire was completely extinguished as the temperature decreased below the flash point of methanol.

Therefore, the droplet size, spray velocity, and spray height have significant effects on fire extinguishment when a sprinkler is installed on a methane-fueled ship. The results of this study can be applied to sprinkler designs as precautionary steps for dealing with small-scale methanol pool fires on ships. Further research is required on sprinkler performance optimization according to fire scale. Methanol pool fires must also be investigated at open sites by considering the effects of wind.

Acknowledgments

This research was supported by the National Research Foundation of Korea(NRF) grant funded by the Korea government (MIST) (No. 2024-0014).

Author Contributions

Writing-Original Draft Preparation, Data Curation, Software, Formal Analysis, Visualization, S.J. Lim., Writing-Review & Editing, Supervision, Conceptualization, Methodology, Investigation, Project Administration, Y.H. Lee;

References

- International Energy Agency (IEA), Net zero by 2050 – A road map for the global energy sector, 2020. https://www.iea.org/reports/net-zero-by-2050, .

- L. Hine, Latest shipping and maritime news. Tradewinds, 2023. https://www.tradewindsnews.com/, .

-

X. Tian, C. Liu, M. Zhong, and C. Shi, “Experimental study and theoretical analysis on influencing factors of burning rate of methanol pool fire,” Fuel, vol. 269, 117467, 2020.

[https://doi.org/10.1016/j.fuel.2020.117467]

- Hazardex news, Four dead after methanol tank explosion in India, 2020. https://www.hazardexonthenet.net/article/176310/Four-dead-after-methanol-tank-explosion-in-India.aspx, .

- S. Y. Kim and Y. G. Kim, “Occupational Health Guidelines for Methanol Handling Workers,” Korea Occupational Safety & Health Agency, 2017.

-

J. Li, T. Beji, S. Brohez, and B. Merci, “Experimental and numerical study of pool fire dynamics in an air-tight compartment focusing on pressure variation,” Fire Safety Journal, vol. 120, 2021.

[https://doi.org/10.1016/j.firesaf.2020.103128]

-

I. Sellami, B. Manescau, K. Chetehouna, C. de Izarra, R. Nait-Said, and F. Zidani, “BLEVE fireball modeling using fire dynamics simulator (FDS) in an Algerian gas industry,” Journal of Loss Prevention in the Process Industries, vol. 54, pp. 69–84, 2018.

[https://doi.org/10.1016/j.jlp.2018.02.010]

-

Y. Mouilleau and A. Champassith, “CFD simulations of atmospheric gas dispersion using the fire dynamics simulator (FDS),” Journal of Loss Prevention in the Process Industries, vol. 22, pp. 316–323, 2009.

[https://doi.org/10.1016/j.jlp.2008.11.009]

-

G. Maragkos and B. Merci, “Grid insensitive modelling of convective heat transfer fluxes in CFD simulations of medium-scale pool fires,” Fire Safety Journal, vol. 120, 103104, 2021.

[https://doi.org/10.1016/j.firesaf.2020.103104]

-

K. C. Adiga, R. F. Hatcher, R. S. Sheinson, F. W. Williams, and S. Ayers, “A computational and experimental study of ultra fine water mist as a total flooding agent,” Fire Safety Journal, vol. 42, no. 2, pp. 150–160, 2007.

[https://doi.org/10.1016/j.firesaf.2006.08.010]

- K. B. McGrattan, S, Hostikka, J. Floyd, H. Baum, and R. Rehm, Fire Dynamics Simulator, fifth version, National Institute of Standards and Technology

-

D. Anderson, J. Tannehill, and R. H. Pletcher, Computational Fluid Mechanics and Heat Transfer 2, Taylor & Francis, pp. 76–78, 2020.

[https://doi.org/10.1201/9781351124027]

- S. C. Kim, S. W. Lee, and W. J. Park, “A sensitivity study of the number of parcels to the numerical simulation of sprinkler sprays,” Journal of Korean Institute of Fire Science and Engineering, vol. 23, no. 1, pp. 48–54, 2009.

-

K. Sung, J. Chen, M. Bundy, M. Fernandez, and A. Hamins, The Thermal character of a 1 m methanol pool fire, National Institute of Standards and Technology, 2021.

[https://doi.org/10.6028/NIST.TN.2083r1]

- S. J. Lim, “A Study on risk assessment and fire extinguishing capacity evaluation in methanol fueled ships”, Mokpo National Maritime University, 2023.

- National Fire Protection Association (NFPA), Standard System for the Identification of the Hazards of Materials for Emergency Response, NFPA 704. 2010. https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=704, .

- IMO, International code of safety for ships using gases or other low-flashpoint fuels, 2015. https://www.imo.org/en/ourwork/safety/pages/igf-code.aspx, .

- National Fire Protection Association (NFPA), Standard System for the Identification of the Hazards of Materials for Emergency Response, NFPA 13, 2022. https://www.nfpa.org/codes-and-standards/all-codes-and-standards/list-of-codes-and-standards/detail?code=13, .

- Methanol Institute, Methanol Safe Handling Manual, fourth ed, 2017. https://www.methanol.org/wp-content/uploads/2017/03/Safe-Handling-Manual.pdf, .

- Green Maritime Methanol, Green Maritime Methanol: Wp 5-System Design for Short Sea Shipping - Six Case Studies of Ships Using Methanol as a Fuel, 2020. https://greenmaritimemethanol.nl/sample-page/

- D. T. Sheppard, Spray characteristics of fire sprinklers. Northwestern University, 2015.

- H. Ikeuchi & Co., Ltd., Hydraulic Spray Nozzles Catalog, 2023. https://www.ikeuchi.eu/downloads-categories/products/, .