Optimal design for pallet size and magazine layout using particle swarm optimization

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Standardized pallets with predefined sizes are widely used in logistics because they help reduce operational costs for transportation firms. However, regular pallets, such as military weapons, are difficult to handle for uncommon cargoes with unique specifications and properties. In such cases, the pallet must be customized to fit the purpose and to optimize the magazine size. This study proposes a metaheuristic called Particle Swarm Optimization (PSO) to calculate the optimal pallet size for weapon cargo based on the specific types and quantities of an assigned weapon list. Next, based on the achieved dimensions, an optimal magazine layout is designed using an exhaustive search method to maximize usage efficiency, which is expressed via the performance index. Simulations are conducted for different input cases to highlight the algorithm's robustness. The final results highlight its implications in the operations management field as it can maximize the space utility of a given storage in different contexts.

Keywords:

Customized pallet, Weapon cargo, Magazine layout, Particle swarm optimization, Exhaustive search1. Introduction

A pallet is an essential basis of logistics because it involves all transportation nodes in a supply chain [1], with 80% of US trade re-portedly carried on pallets [2], making pallets the most standard platform to handle unit loads worldwide. The ISO standards for pallet size vary among countries, such as the US (1219 mm × 1016 mm), Australia (1165 mm × 1165 mm), and Europe (1200 mm × 800 mm). In South Korea, the national standard for pallet dimensions was adjusted in 2013 [3] to include the T-12 type (1200 mm × 1000 mm) and T-11 type (1100 mm × 1100 mm). The standardized pallet has apparent advantages in unifying criteria among transportation firms, reducing cost and time for disagreements of delivery principles, and providing a wider range of alternatives for handling equip-ment, as standardized modules can be replaced with each other.

Nonetheless, in the case of special cargo, which has unique properties and distinct handling procedures and constraints compared with conventional products [4], customized pallets are preferred because they are specifically designed for each task. Heavy and over-sized cargo usually requires nonstandard large pallets that can handle their extreme dimensions. Thus, many major companies have de-signed their own pallets, particularly for automobile, robotics, and military enterprises.

It should be noted that although a customized pallet is made to serve a specific use, only the size and weight of the item are considered because they directly affect the space utility of the pallet, which is fundamental in the warehousing area. Given the specific size and max-imum storage capacity, it is important to identify the best way to use the available space, thus minimizing the operational cost by reduc-ing the unused space and number of pallets required. This was the main objective of this study.

Hodson [5] considered a combined approach for the pallet-loading problem, which is a two-dimensional problem in which rectangu-lar boxes are loaded on a rectangular pallet. Dynamic programming and a heuristic approach were combined to maximize the pallet area covered by loaded boxes.

Park et al. [6] attempted to detect the number of boards required for a certain number of coils by using a First-Fit Decreasing algo-rithm to minimize the number of pallets required.

Kye et al. [7] explored the impact of packaging logistics on freight transportation efficiency by identifying the optimal pattern for loading nonuniform boxes on standardized pallets to achieve the minimum number of pallets required.

Elia and Groni [8] designed an effective closed-loop system and outlined the critical factors. They also designed organizational sce-narios and evaluated the cost and time of the simulation model.

Roy et al. [1] conducted a comprehensive study on pallet management strategies to achieve cost efficiency. They compared three methods: single-use, buy/sell, and leased pallets. They also developed a cost relationship using the outputs obtained from other stochas-tic models and analyzed the effect of different fees on strategy performance.

Tornese et al. [9] conducted an extensive analysis of pallet use in a supply chain, considering open- and closed-loop models for the decision-making schemes and different stakeholders. This review serves as a guide for practitioners to improve their economic and envi-ronmental performance.

Rojas [10] considered the effect of pallet design on the performance of semi-automated and fully automated warehouses in his master dissertation. The author proposed guidelines to improve warehouse performance through surveys and questionnaires and identified the pallet characteristics required for specific applications.

Saderova et al. [11] proposed a layout design for a rack system considering several factors, such as rack dimensions, working aisle width, and traffic aisle width. The authors also deployed a Warehouse Management System to increase working efficiency by monitor-ing internal movements and states.

Sawicki and Sawicka [12] investigated the optimal design of stacked pallet load units comprising at least two stackable units without exceeding the allowed height or weight. Single-criteria binary programming was applied to minimize the pallet spaces required to ac-commodate the constructed units.

Raghuram and Arjunan [13] developed a framework for designing a warehouse using lean principles by referring to the inputs and outputs of the production line process flow. They concluded that the effective use of space and resources leads to better storage efficien-cy.

Yener and Yazgan [14] conducted a comprehensive review of optimal warehouse design and case study applications. The authors in-vestigated the effectiveness of designing warehouses using data-mining techniques to reduce the average order-picking time and travel distance.

Numerous studies have focused on pallet design, including its material and dimensions, but have primarily considered standard pallets for common cargo. Regarding exceptional products, the literature concentrates only on structural design to fit the item’s characteristics, while the pallet’s dimensions and loading patterns have not yet been explored clearly. In addition, no previous studies have simultane-ously considered pallet and layout designs.

Thus, in this study, optimization problems for both pallet dimensions and layout design are addressed, considering the specifications for every package type of special products in the given list and the physical handling limits of the pallet. The achieved pallet size is used to detect the best layout given known dimensions and is evaluated using a performance index.

The remainder of this paper is organized as follows: Section 2 describes the mathematical model for the pallet size optimization prob-lem and how to solve it using Particle Swarm Optimization. Section 3 describes the magazine layout design based on the optimal pallet size achieved in the previous section. Section 4 presents numerical simulation results to validate the proposed algorithm, and Section 5 presents the final conclusions.

2. Optimal Pallet Size with Particle Swarm Optimization

2.1 Problem Description

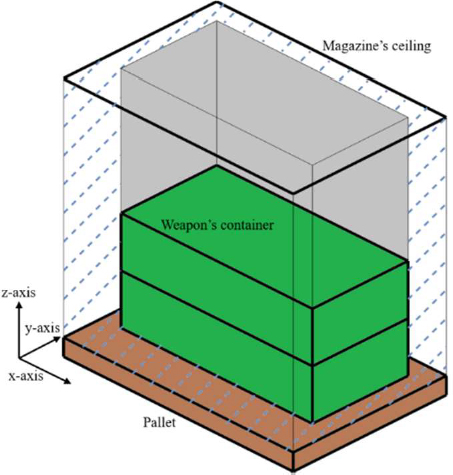

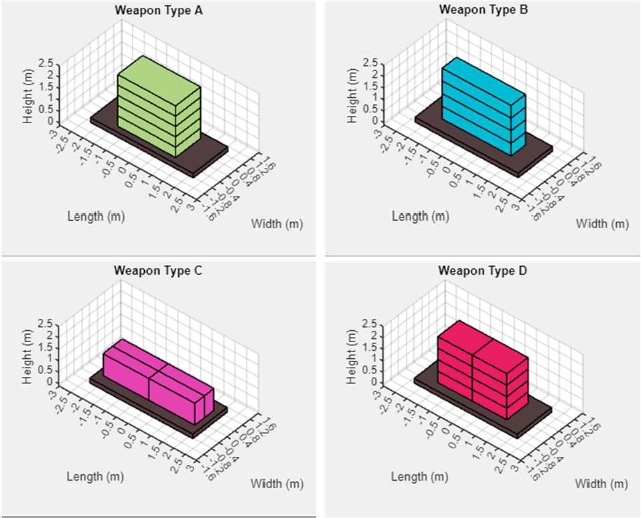

The main problems in this study are described as follows: Assume a magazine with a specific list of weapon containers divided into several main types. The specifications of each type, including the dimensions, weight, and number of boxes inside each container, were known. All weapons are stacked on single-layer pallets on the floor, where special transport tools, called moles, move horizontally and vertically across the layout to pick them up. Because of the height limitation of the magazine and the physical handling workload of the pallet, weapon containers were placed on the pallet such that the total stacking weight did not exceed the upper limit of the pallet, and the total stacking height was capped below the height of the magazine. The loss of space on each pallet is defined as the volume between the pallet and the magazine ceiling, where no more containers can be added, as illustrated in Figure 1.

Owing to the restriction of the stacking weight and physical alignment, the volume marked in gray and by the dashed lines cannot be used for any more stacks and is thus considered a loss of space. Because there are many containers of different types and sizes, the ob-jective is to define the best pallet size so that the total loss of space caused by all the stacked containers is minimized.

2.2 Mathematical Model

Assume that K weapon types exist with unit quantity Qi and container size (LCi, WCi, HCi) (i=1,2...,K). Each container type i can have NCi unit boxes. The mathematical model of the optimization problem is formulated as follows:

| (1) |

subject to

| (2) |

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

| (8) |

| (9) |

where [Lmin, Lmax] and [Wmin, Wmax] are the ranges of the feasible lengths and widths of the pallets, respectively.

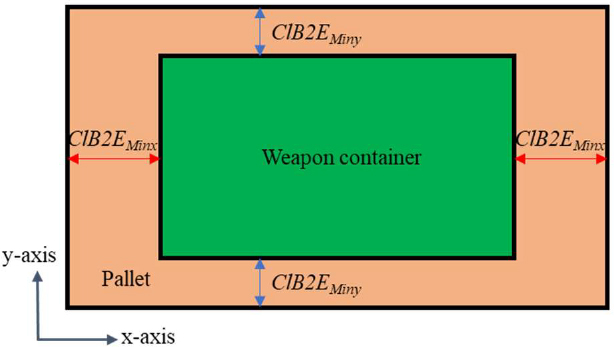

Equation (1) defines the total loss as the loss of space for all pallets belonging to each weapon type. Equation (2) calculates the number of containers required per container type. Equation (3) determines the stacking pattern (nxi,nyi,nzi) on a pallet along the x-, y-, and z-axes. For example, as shown in Figure 1, the stacking pattern is (nxi,nyi,nzi)=(1,1,2). Equation (4) determines the number of pellets required for each type. Equation (5) defines the lost space on each pallet as a function of the pallet size (L,W). Equations (6) and (7) describe the limits of the stacking height HLimit and stacking weight GPalLimit of the pallet, considering the properties of the weapon type and the default values HPalDefault and GPalDefault of the pure pallet (without any loads). Equations (8) and (9) guarantee the existence of a feasible solution (L,W), as the pallet must be capable of handling the largest container in the list concerning the minimum clearance values ClB2EMinx along the x- and y-axes, which are defined in Figure 2.

2.3 Particle Swarm Optimization

Particle Swarm Optimization (PSO) is a swarm-based metaheuristic originally introduced by Kennedy and Eberhart [15] to simulate the behavior of bird flocks. PSO has been recognized as a popular yet robust algorithm for solving combinatorial optimization problems and has been applied in various research fields. In the PSO, each candidate solution u is encoded as a particle coordinated by its position pu and velocity Vu. The position pu reveals the current state of the u, whereas the velocity Vu indicates its direction of evolution. After every iteration, pu and Vu are updated to optimize a specific objective function. Finally, all the particles tend to gather at a single point, presenting the optimal solution in the state space.

Generally, the particle is updated per iteration based on the following formulas:

| (10) |

| (11) |

where (w,C1,C2)∈R+ are real-valued coefficients representing the inertial, cognitive, and social factors. (r1,r2)∈[0,1) is a random number generated per iteration to avoid becoming stuck in local optima. plocal (t) is the best particle in this iteration, and pglobal (t) is the best record among all particles up to the current moment of t. Assuming that the target of the problem is to minimize the objective function J(p,t),

| (12) |

| (13) |

3. Optimal Layout Design for Magazine

3.1 Problem Description

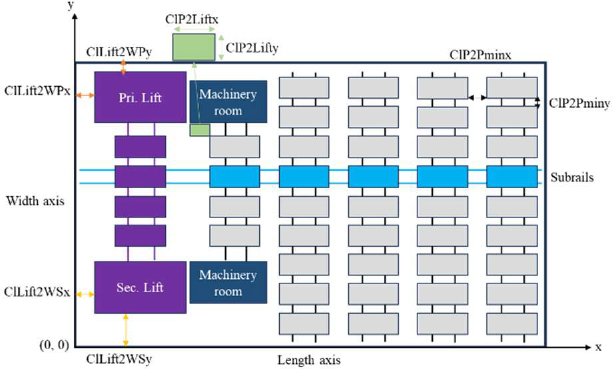

A layout is considered optimal when it maximizes usage efficiency. Generally, in the logistics field, the key objectives are to minimize the average storage and retrieval time for all allocated items, minimize the configuration cost, and maximize capacity. This study requires an optimal layout for a multistory magazine, given the dimensions of the outer boundary and associated equipment inside. The equip-ment consisted of two lifts located at the corners, two machinery rooms next to the lifts, and a set of parallel rails that moved pallets in the horizontal and vertical directions. Some notable devices called “moles” are placed on the rails that can move along the rails to reach the pallet positions. The rails that directly lead to the lifts are called “main rails,” while the rails directly linked to the pallets are called “normal rails.”

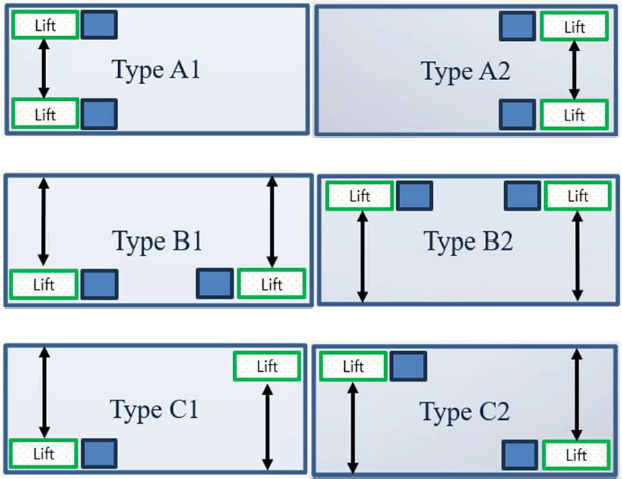

In the scope of this study, the normal rails and the main rails must be connected via intermediate rails called “sub-rails.” The number of subrails was capped at two in either the vertical or horizontal direction, and the normal rails were oriented in the same direction. Due to the physical limitations, there is a list of options for lift allocation, divided into six main groups named “A1,” “A2,” “B1,” “B2,” “C1,” and “C2.” Figure 3 illustrates the lift configurations of the groups. The black arrows represent the main rails, and the blue arrows indicate the positions of the machinery rooms.

3.2 Performance Index (PIndex)

To evaluate the design quantitatively, a metric termed PIndex was introduced, which is expressed as a weighted sum as follows:

| (14) |

where (w1,w2,w3,w4)∈[0,1] are the weight factors, tavg is the average time from all pallet positions to the lifts, QMole is the number of moles used in the layout, QAccess is the number of accessible pallets defined as the ones being closest to the sub-rails from the normal rails, and LossSpace indicates the space occupied by the pallets. Assuming that the layout can allocate at most QCapacity pallets, LossSpace can be formulated as follows:

| (15) |

where (LPalOpt,WPalOpt) is the optimal pallet size achieved from the previous section.

Consequently, Equation (14) compromises the minimization of retrieval time, the minimization of facility cost, and the maximization of accessibility and capacity, which makes sense in the logistics field, as these are all fundamental objectives and play a vital role in over-all efficiency.

According to the semantic meaning of Equation (14), a lower PIndex indicates a better layout. There might be more than one possi-ble layout that shares the same PIndex value; therefore, a layout with less is considered better because time is supposed to be superior to other aspects in most cases. The best layout is found using an exhaustive search in which all possible layouts are enumerated along with their PIndex, and the one with the lowest PIndex is identified. In the next section, the performance of the proposed approach is demon-strated via numerical results for different contexts and input values.

4. Numerical Results

Numerical simulations were performed to verify the effectiveness of the proposed algorithm. First, the following assumptions were made to clarify the context of the simulation:

- ① A list of weapons with specific specifications is provided in Table 1.

- ② Constraints and clearance values of the pallet are provided in Table 2 below.

- ③ Default height and weight of the pallet are set as HPalDefault = 20cm and GPalDefault = 100kg.

- ④ The optimal pallet size obtained will be used to design the layouts.

- ⑤ The magazine has three floors, and the layout on every floor is identical.

- ⑥ The sizes of lifts and magazines are fixed.

- ⑦ The locations of the machinery rooms were fixed next to the lifts, and their size was capped at 80% of the lift size.

- ⑧ Mole speed is identical for all available moles in the layout.

- ⑨ In addition to the loaded pallets, 10% of the total pallet quantities are empty pallets.

The algorithm is implemented on Matlab R2023a, which is a computational software from Mathworks company that specializes in numerical calculation and data visualization for academic researchers.

4.1 Optimization for Pallet Size

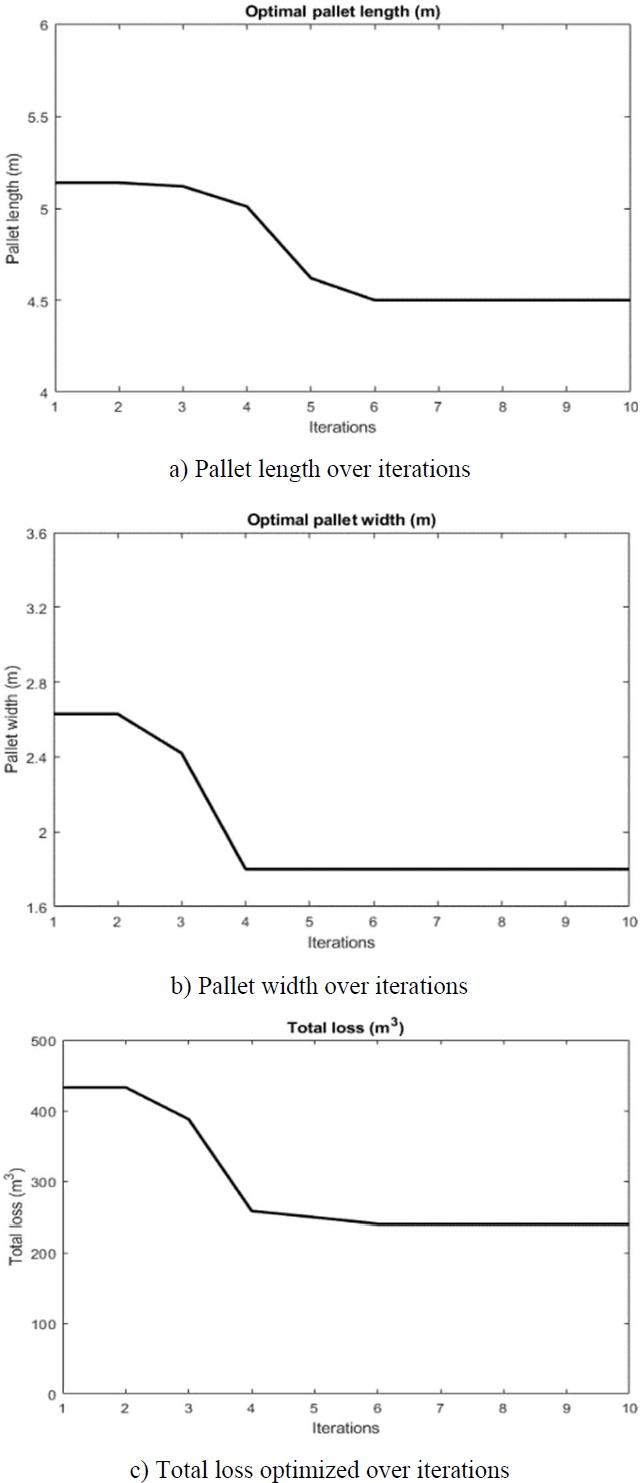

The optimal pallet size was determined using the procedure described in Section 2, and the parameters are listed in Table 3, as shown in the charts in Figure 4 a) – c). The results show rapid convergence of the optimal solution, where the final values are(LPalOpt,WPalOpt)=(4.5,1.8).

Figure 5 shows the containers for each stacking type on the optimal pallet. Table 4 summarizes the results in detail. The total number of pallets required to handle all containers was 18, including one empty pallet, as required for the task.

4.2 Optimization for Layout Design

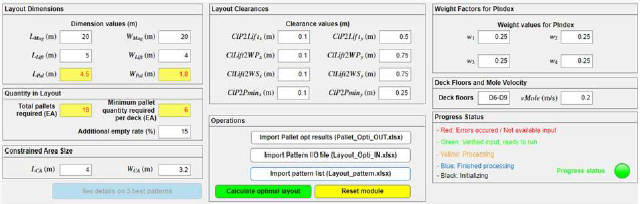

The layout design is considered next using the pallet size. Figure 6 presents the inputs of the user interface program for the layout, consisting of the dimensions of the components, weight factors of the PIndex expression, mole velocity, and clearances between the components. All clearance terms are defined in Figure 7.

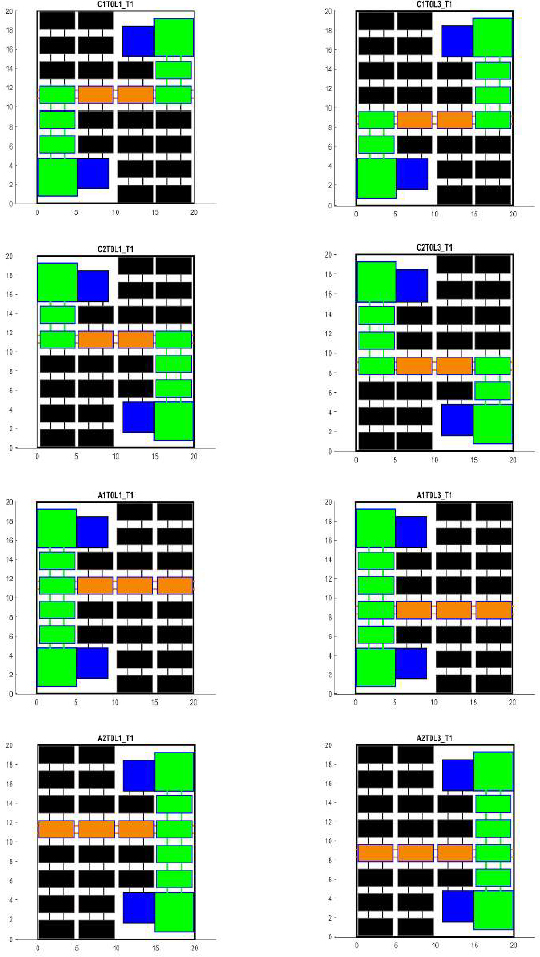

Following an exhaustive search, all the possible layout options were enumerated. For each option, the pallet positions were placed as far as possible in the layout without violating the minimum clearances defined in Figure 7. There are always two possible alignments for normal rails: vertical and horizontal. It should be noted that the main rails of all groups are vertical; hence, there must be at least one horizontal sub-rail because it connects the main and normal rails. Furthermore, the feasible layouts must be able to handle the required number of pallets per deck; hence, unsatisfactory options are discarded from the candidate list. Figure 8 visualizes all satisfied layouts, while Table 5 sorts the results in ascending order of PIndex. C1T0L1_T1, C1T0L3_T1, C2T0L1_T1, and C2T0L3_T1 are the four optimal layouts because they share the minimum PIndex.

5. Conclusions

To summarize, this study considers two problems simultaneously: calculating an optimal pallet size for a given list of items with dif-ferent types and specifications and finding the best layout for a multistory magazine given the magazine size and optimal pallet size ob-tained. These problems play a crucial role in logistics and warehousing operations management. The results obtained are helpful for strategic managers and decision-makers, as they strongly reduce operational costs and boost space utility. Given any list of palletized products with known specifications and predefined storage size, the proposed algorithm can be applied to determine the pallet size that best fits the case and minimizes the total loss of space.

For practical implications, this study provides a mathematical model for optimizing the pallet size and layout design, which is more straightforward and precise than using a predefined standard. The proposed method supports the design of nonstandardized pallets, considering the specifications and quantity of every individual container for a specific mission. Manufacturers can refer to this approach when considering a particular requirement for a standardless pallet, particularly to minimize the total loss of space in a specific storage area.

Regarding layout design, this study provides an objective function that covers all the common aspects of warehousing, such as aver-age moving time, package accessibility, facility resources, and total volume used. Based on the objective's priority, designers can adjust the weight factors accordingly, making this method flexible and applicable to other storage and warehousing systems.

This study considers a list of configurations based on the lift position of the layout. The performance index expressed in Equation (14) can be generalized for other cases because it still covers the core objective aspects of layout optimization: minimizing time and fa-cility costs while maximizing utility and efficiency. In future work, the idea in this study can be extended and enhanced by adding more realistic constraints, such as varying the allocation of rails and lifts to be more complex or by considering the traffic conditions of the moles used in the layout.

Acknowledgments

This research was supported by the Defense Rapid Acquisition Technology Research Institute, Korea (UC200008D).

Author Contributions

Conceptualization, S. P. Lee and H. S. Kim; Methodology, S. P. Lee; Software, S. P. Lee; Validation, C. W. Ha; Formal Analysis, C. W. Ha; Investigation, S. P. Lee & H. S. Kim; Resources, C. W. Ha; Data Curation, C. W. Ha; Writing-Original Draft Preparation, S. P. Lee; Writing-Review & Editing, H. S. Kim; Visualization, S. P. Lee; Supervision, C. H. Kim; Project Administration, C. H. Kim; Funding Acquisition, C. H. Kim.

References

-

D. Roy, A. L. Carrano, J. A. Pazour, and A. Gupta, “Cost-effective pallet management strategies,” Transportation Research Part E: Logistics and Transportation Review, vol. 93, pp. 358-371, 2016.

[https://doi.org/10.1016/j.tre.2016.06.005]

-

G. Raballand and E. Aldaz-Carroll, “How do differing standards increase trade costs? The case of pallets,” World Economy, vol. 30, no. 4, pp. 685-702, 2007.

[https://doi.org/10.1111/j.1467-9701.2007.01009.x]

- Korea Agency for Technology and Standards, General Rules for Unit Load Systems (KS T 0006), 2013 (in Korean).

- J. H. Baek, A Study on Determination of Air Freight Forwarder - Focused on Special Cargo Transportation, M. S. Thesis, Graduate School of Logistics, Inha University, Korea, 2020 (in Korean).

-

T. J. Hodson, “A combined approach to the pallet loading problem,” IIE Transactions, vol. 14, no. 3, pp. 175-182, 1982.

[https://doi.org/10.1080/05695558208974601]

- J. H. Park, et al., “On optimal design methods for steel product pallets,” Journal of the Korean Institute of Industrial Engineers, vol. 34, no. 4, pp. 470-480, 2008 (in Korean).

-

D. -M. Kye, J. -G. Lee, and K. -D. Lee, “The perceived impact of packaging logistics on the efficiency of freight transportation (EOT),” International Journal of Physical Distribution & Logistics Management, vol. 43, no. 8, pp. 707-720, 2013.

[https://doi.org/10.1108/IJPDLM-08-2011-0143]

-

V. Elia and M. G. Groni, “Designing an effective closed loop system for pallet management,” International Journal of Production Economics, vol. 170, Part C, pp. 730-740, 2015.

[https://doi.org/10.1016/j.ijpe.2015.05.030]

-

F. Tornese, M. G. Groni, B. K. Thorn, A. L. Carrano, and J. A. Pazour, “Management and logistics of returnable transport items: A review analysis on the pallet supply chain,” Sustainability, vol. 13, no. 22, 2021.

[https://doi.org/10.3390/su132212747]

- A. M. Rojas, Case Study: The Effect of Pallet Design on the Performance of Semi-Automatic & Fully-Automatic Warehouses, M. S. Thesis, Virginia Polytechnic Institute and State University, USA, 2019.

-

J. Saderova, L. Poplawski, M. Balog Jr, S. Michalkova, and M. Cvoliga, “Layout design options for warehouse management,” Polish Journal of Management Studies, vol. 22, no. 2, pp. 443-455, 2020.

[https://doi.org/10.17512/pjms.2020.22.2.29]

-

P. Sawicki and H. Sawicka, “Design optimization of stacked pallet load units,” Applied Sciences, vol. 13, no. 4, 2023.

[https://doi.org/10.3390/app13042153]

-

P. Raghuram and M. K. Arjunan, “Design framework for a lean warehouse – a case study-based approach,” International Journal of Productivity and Performance Management, vol. 71, no. 6, pp. 2410-2431, 2022.

[https://doi.org/10.1108/IJPPM-12-2020-0668]

-

F. Yener and H. R. Yazgan, “Optimal warehouse design: Literature review and case study application,” Computers & Industrial Engineering, vol. 129, pp. 1-13, 2019.

[https://doi.org/10.1016/j.cie.2019.01.006]

- J. Kennedy and R. Eberhart, “Particle swarm optimization,” Proceedings of ICNN'95 - International Conference on Neural Networks, Australia, 1995.