Recrystallization kinetics and the mechanical properties of low-carbon steel during high-temperature annealing in electric furnace

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

In this study, we investigated the microstructures and mechanical properties of annealed cold-rolled low-carbon steels. The specimens were subjected to different annealing temperatures and durations in an electric furnace to investigate their recrystallization phenomena. Recrystallization kinetics were analyzed through microstructural evolution by evaluating various mechanical properties. The results showed that the samples annealed at 700 °C were fully recrystallized with equiaxed grains, whereas equiaxed recrystallized grains began to grow in the samples annealed at 800 °C after 10 min of soaking. Electron backscatter diffraction grain orientation spread maps were used to quantify the percentage of recrystallized grains as a function of annealing temperature and soaking time. The samples annealed at 800 °C with 10 min of soaking exhibited good elongation (approximately 38%) and tensile strength (exceeding 270 MPa).

Keywords:

Low-carbon steel, Annealing, Electric furnace, Recrystallization, Mechanical properties1. Introduction

The shipbuilding industry is constantly working to improve offshore and subsea structures in response to the increasing de-mand for natural resources, including oil and gas, in underwater environments. Low-carbon steel plates/sheets are widely used in marine industries for major parts of offshore structures that re-quire specific properties such as high strength, high impact toughness, excellent weldability, and corrosion resistance [1]-[3]. Grain refinement is a useful strategy for establishing the desired characteristics of the plates [4]-[8]. Of the several grain refining methods, cold rolling followed by annealing has been one of the most efficient, effective, and low-cost techniques [7][8]. Recrys-tallization is a common means of investigating the relationship between structure and mechanical properties in carbon steels [9][10].

Recrystallization refers to a high-temperature annealing phe-nomenon driven by the energy stored in lattice strains and crystal imperfections, such as dislocations, during the deformation pro-cess, thereby relaxing the stress in deformed steel when annealed at a particular temperature [10]-[12].

Ferry et al. performed continuous annealing of cold-rolled (CR) low- and ultralow-carbon steel [13]. Their annealing model, based on the Avrami equation, predicted that the cooling rate and soaking time strongly affect the recrystallization kinetics. Martinez-de-Guerenu et al. measured the hardness of recrystallized CR low-carbon steel [14]. They found that after annealing at approximately 600 ℃ and 10 s of soaking, the measured Rockwell hardness values decreased as recrystalliza-tion initiated. Akbari et al. studied the recrystallization kinetics and mechanical properties of low-carbon steel at three different temperatures: room tempera-ture, blue-brittleness, and sub-zero temperature [15]. They demonstrated that pre-straining at sub-zero temperature followed by annealing at 600 ℃ enhanced the mechanical properties and recrystallization kinetics better than at room and blue brittleness temperatures. Tian et al. re-ported that ultrafine-grained martensitic low-carbon steel exhibit-ed superior mechanical properties after annealing at 550 ℃ for 30 min [16]. However, these studies used conventional heat treat-ment, which is time- and energy-inefficient, and a major source of CO2 emissions. Thus, we investigated the recrystallization kinetics of CR low-carbon steel heat-treated in an electric furnace through microstructural evolution, and measured the mechanical proper-ties of the annealed steel specimens.

2. Experimental Method

Commercial-quality CR low-carbon full hard steel sheets (0.04 C, 0.25 Mn, 0.035 Al, <0.019 P, <0.015 S, Fe balanced in wt. %; 340 × 300 × 1 mm3) were annealed in an electric furnace at 700 or 800 ℃, soaked for 5 and 10 min, then air cooled. The speci-mens were cut to 200 × 70 × 1 mm3 and 10 × 10 × 1 mm3 for tensile tests and microstructural studies, respectively. Optical mi-croscopy (OM; Leica, DM750), field-emission scanning electron microscopy (FE-SEM; Carl Zeiss, SUPRAA40VP), and scan-ning electron microscopy/electron backscatter diffraction (SEM-EBSD; JEOL, JIB-4601F) were used for microstructural investi-gations. Optical microscopy and SEM were conducted on speci-mens mechanically polished with emery papers (1000–2400 grit size) and finely polished with a 1-µm diamond suspension, fol-lowed by chemical etching with 10% nital solution. The speci-mens were electropolished at 10 V in an acetic acid and perchloric acid solution (80:20) for EBSD characterization. The stress–strain behavior was determined through tensile tests performed at room temperature using a universal testing machine (INSTRON, 8801MTL6258) according to the standard ASTM E8/E8M-22. The Vickers hardness was also measured.

3. Results and Discussion

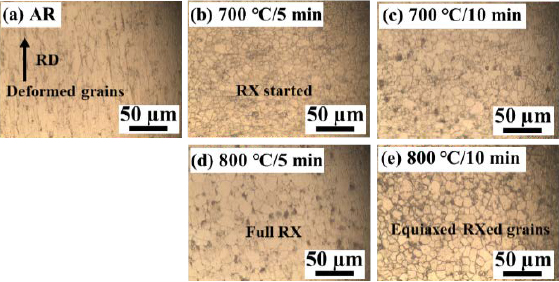

Figure 1 shows optical micrographs of the annealed and as-received (AR) samples. The deformed grains are elongated along the rolling direction of the AR sample. After annealing at 700 ℃ with 5 and 10 min of soaking time, as shown in Figures 1 (b) and (c), respectively, static recrystallization initiated with the nucleation of new strain-free grains. In the samples annealed at 800 ℃, equiaxed recrystallized grains were observed [17][18].

Optical micrographs showing (a) deformed grains elongated along the rolling direction in the AR sample, (b–e) re-crystallization phenomena in the annealed samples

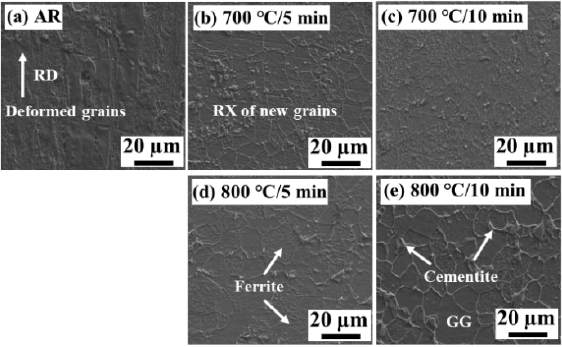

Visualization of the microstructures of the samples using FE-SEM, as shown in Figure 2 (a)-(e), revealed similar observa-tions. Heavily deformed grains extend along the rolling direction in the AR sample. Recrystallization was triggered by annealing at 700 ℃, and no microstructural differences were seen in terms of soaking time at this temperature. Full recrystallization occurred in the sample annealed at 800 °C with 5 min of soaking, with equi-axed grains formed throughout. The sample annealed at 800 °C with 10 min of soaking evinced that equiaxed grains started growing when the soaking time increased, as shown in Figure 2 (e). The microstructures of the annealed samples were primarily composed of recrystallized ferrite grains with a small fraction of cementite that tended to nucleate at the grain boundaries [15][19].

SEM images showing (a) deformed grains elongated along the rolling direction in the AR sample, and (b–e) recrystal-lization phenomena in the annealed samples; GG refers to grain growth

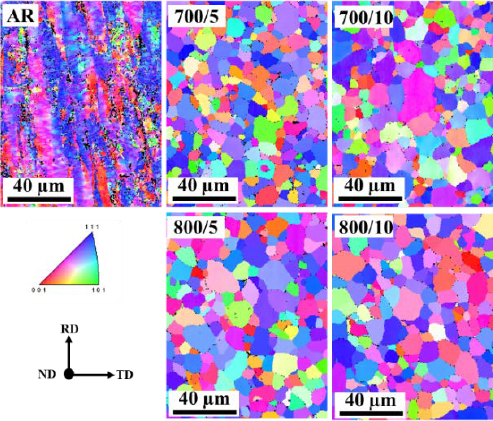

Inverse pole figures were obtained to examine the textural evo-lution of the annealed specimens, which showed recrystallized ferrite grains oriented along <111> // ND and <110> // ND, as shown in Figure 3 [20]-[22]. The strong texture indicates that recrystallization occurred after annealing at both temperatures.

Inverse pole figure maps showing recrystallized ferrite grains oriented along <111> //ND and <110> //ND in annealed samples

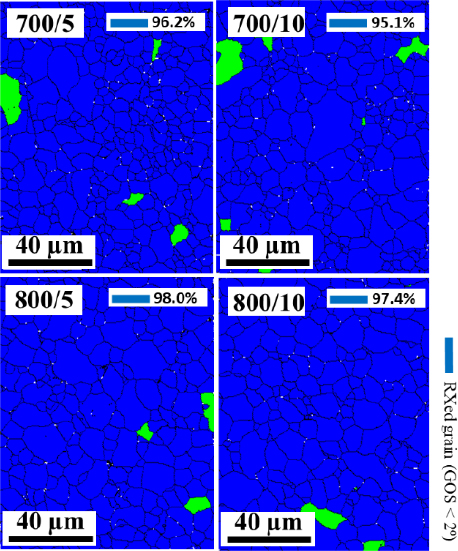

The percentages of recrystallized grains formed in the annealed samples are indicated by the grain orientation spread maps shown in Figure 4. The percentage of recrystallization is increased by 2–3% with the increase in annealing temperature, from approxi-mately 95–96% at 700 ℃ to 97–98% at 800 ℃. Moreover, the soaking duration has a minimal effect on the recrystallization percentage at both annealing temperatures [22].

Grain orientation spread (GOS) maps showing the re-crystallization percentage in the annealed samples. GOS < 2° are treated as recrystallized grains [22]

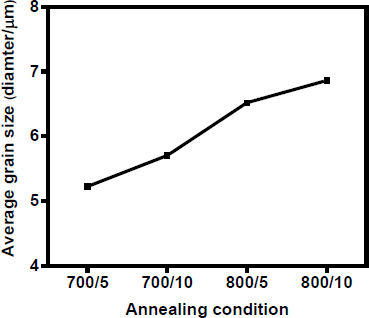

The average grain size of the annealed samples was measured and it was observed that the average size of the recrystallized grains increased with annealing temperature and soaking time, as shown in Figure 5. The average grain size for the specimen an-nealed at 700 °C and soaked for 5 min was approximately 5 µm, whereas the specimen annealed at 800 °C and soaked for 10 min had the largest grain size, measuring approximately 7 µm. This validated the phenomenon of grain development that occurred throughout the annealing process.

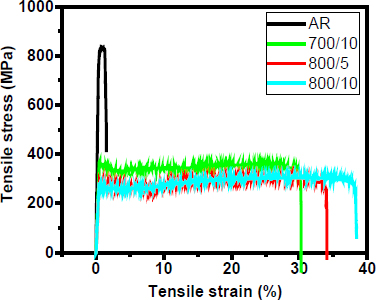

To investigate the effect of heat treatment on the mechanical properties, tensile tests were conducted on all samples. The ten-sile strength (TS) and strain obtained for each specimen are listed in Table 1, and the stress–strain curves are shown in Figure 6. The annealing temperature influenced TS: the TS of the annealed samples was nearly three times lower than that of the AR sam-ples. The samples annealed at 800 ℃ exhibited greater elongation and lower TS than those annealed at 700 ℃. Soaking time had negligible effect on the ductility of the annealed specimens: the sample annealed at 800 °C and soaked for 10 min showed 38% elongation, four percentage points more than the sample annealed at 800 °C and soaked for 5 min.

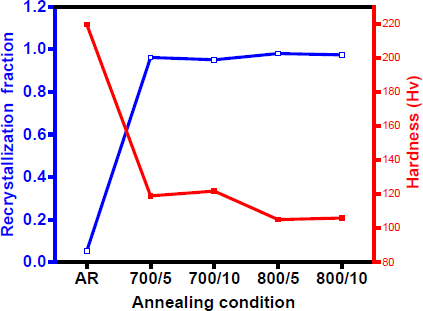

The Vickers hardness of all the specimens was measured as an indicator of recrystallization. Figure 7 shows the recrystallization fraction and Vickers hardness as functions of the annealing con-ditions. As the annealing temperature and duration increased, the hardness decreased, whereas the recrystallization fraction in-creased proportionally. The increased average grain size in sam-ples annealed at 800 ℃ led to a reduction in hardness compared to those annealed at 700 ℃.

Measured recrystallization fraction and corresponding Vickers hardness values plotted as a function of annealing condition

The progression of recrystallization was examined via micro-structural analysis and mechanical property measurements. The tensile strength and hardness of the specimens decreased with increasing annealing temperature and time, suggesting an increase in recrystallization with increased annealing parameters. This trend is further evident in the EBSD map, where the highest pro-portion of recrystallized grains is observed in the samples an-nealed at 800 °C.

4. Conclusion

This study analyzed the recrystallization of CR low-carbon steel annealed in an electric furnace at either 700 ℃ or 800 ℃ with 5 or 10 min of soaking. The following conclusions were drawn.

- 1) OM, SEM, and EBSD showed that annealing at 700 ℃ for 5 min is sufficient to initiate recrystallization.

- 2) Ferrite grains form after soaking for 10 min at 800 ℃.

- 3) The sample annealed at 800 °C and soaked for 10 min ex-hibited an excellent elongation of 38% and approximately 270 MPa tensile strength.

Acknowledgments

The study was supported by a National Research Foundation of Korea (NRF) grant funded by the Korean government (Minis-try of Science and ICT) (grant no. 2022R1A2C1008972) and the Ministry of Trade, Industry, and Energy (MOTIE) and the Korea Institute of Energy Technology Evaluation and Planning (KETEP) in 2023 (grant no. RS-2023-00233397).

Author Contributions

Conceptualization, S. K. Pradhan and M. S. Oh; Methodology, S. K. Pradhan and M. S. Oh; Validation, S. K. Pradhan and M. S. Oh; Formal Analysis, S. K. Pradhan and M. S. Oh; Writing—Original Draft Preparation, S. K. Pradhan; Writing—Review & Editing, M. S. Oh; Visualization, S. K. Pradhan and M. S. Oh.

References

-

G. Liang, Q. Tan, Y. Liu, T. Wu, X. Yang, Z. Tian, A. Atrens, and M. X. Zhang, “Effect of cooling rate on micro-structure and mechanical properties of a low-carbon low-al-loy steel,” Journal of Materials Science, vol. 56, no. 5, pp. 3995-4005, 2021.

[https://doi.org/10.1007/s10853-020-05483-9]

-

S. S. Kang, A. Bolouri, and C. -G. Kang, “The effect of heat treatment on the mechanical properties of a low carbon steel (0.1%) for offshore structural application,” Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications, vol. 226, no. 3, pp. 242-251, 2012.

[https://doi.org/10.1177/1464420712438502]

-

A. Bolouri, T. -W. Kim, and C. G. Kang, “Processing of low-carbon cast steels for offshore structural applications,” Materials and Manufacturing Processes, vol. 28, no. 11, pp. 1260-1267, 2013.

[https://doi.org/10.1080/10426914.2013.792424]

-

T. W. Yin, Y. F. Shen, N. Jia, Y. J. Li, and W. Y. Xue, “Controllable selection of martensitic variant enables con-current enhancement of strength and ductility in a low-car-bon steel,” International Journal of Plasticity, vol. 168, p. 103704, 2023.

[https://doi.org/10.1016/j.ijplas.2023.103704]

-

T. Inoue and R. Ueji, “Improvement of strength, toughness and ductility in ultrafine-grained low-carbon steel processed by warm bi-axial rolling,” Materials Science and Engineer-ing: A, vol. 786, p.139415, 2020.

[https://doi.org/10.1016/j.msea.2020.139415]

-

J. Sun, C. Yang, S. Guo, X. Sun, M. Ma, S. Zhao, and Y. Liu, “A novel process to obtain lamella structured low-car-bon steel with bimodal grain size distribution for potentially improving mechanical property,” Materials Science and En-gineering: A, vol. 785, p. 139339, 2020.

[https://doi.org/10.1016/j.msea.2020.139339]

-

R. Ueji, N. Tsuji, Y. Minamino, and Y. Koizumi, “Ultra-grain refinement of plain low carbon steel by cold-rolling and annealing of martensite,” Acta Materialia, vol. 50, no. 16, pp. 4177-4189, 2002.

[https://doi.org/10.1016/S1359-6454(02)00260-4]

-

A. Karmakar, M. Mandal, A. Mandal, M. B. Sk, S. Mukher-jee, and D. Chakrabarti, “Effect of starting microstructure on the grain refinement in cold-rolled low-carbon steel dur-ing annealing at two different heating rates,” Metallurgical Materials Transactions A, vol. 47, no. 1, pp. 268-281, 2016.

[https://doi.org/10.1007/s11661-015-3248-y]

-

H. Mao, R. Zhang, L. Hua, and F. Yin, “Study of static re-crystallization behaviors of GCr15 steel under two-pass hot compression deformation,” Journal of Materials Engineer-ing and Performance, vol. 24, no. 2, pp. 930-935, 2015.

[https://doi.org/10.1007/s11665-014-1264-5]

-

K. K. Alaneme and E. A. Okotete, “Recrystallization mech-anisms and microstructure development in emerging metal-lic materials: A review,” Journal of Science: Advanced Ma-terials and Devices, vol. 4, no. 1, pp. 19-33, 2019.

[https://doi.org/10.1016/j.jsamd.2018.12.007]

-

P. R. Rios, F. Siciliano Jr, H. R. Z. Sandim, R. L. Plaut, and A. F. Padilha, “Nucleation and growth during recrystalliza-tion,” Materials Research, vol. 8, no. 3, pp. 225-238, 2005.

[https://doi.org/10.1590/S1516-14392005000300002]

-

Y. Lü, D. A. Molodov, and G. Gottstein, “Recrystallization kinetics and microstructure evolution during annealing of a cold-rolled Fe–Mn–C alloy,” Acta Materialia, vol. 59, no. 8, pp. 3229-3243, 2011.

[https://doi.org/10.1016/j.actamat.2011.01.063]

-

M. Ferry, D. Muljono, and D. P. Dunne, “Recrystallization kinetics of low and ultra low carbon steels during high-rate annealing,” ISIJ International, vol. 41, no. 9, pp. 1053-1060, 2001.

[https://doi.org/10.2355/isijinternational.41.1053]

-

A. Martınez-de-Guerenu, F. Arizti, M. Díaz-Fuentes, and I. Gutiérrez, “Recovery during annealing in a cold rolled low carbon steel. Part I: Kinetics and microstructural character-ization,” Acta Materialia, vol. 52, no. 12, pp. 3657-3664, 2004.

[https://doi.org/10.1016/j.actamat.2004.04.019]

-

E. Akbari, K. K. Taheri, and A. K. Taheri, “The effect of prestrain temperature on kinetics of static recrystallization, microstructure evolution, and mechanical properties of low carbon steel,” Journal of Materials Engineering and Perfor-mance, vol. 27, no. 5, pp. 2049-2059, 2018.

[https://doi.org/10.1007/s11665-018-3328-4]

-

J. Tian, G. Xu, W. Liang, and Q. Yuan, “Effect of annealing on the microstructure and mechanical properties of a low-carbon steel with ultrafine grains,” Metallography, Micro-structure, and Analysis, vol. 6, no. 3, pp. 233-239, 2017.

[https://doi.org/10.1007/s13632-017-0350-0]

-

M. Oyarzábal, A. Martínez-de-Guerenu, and I. Gutiérrez, “Effect of stored energy and recovery on the overall recrys-tallization kinetics of a cold rolled low carbon steel,” Mate-rials Science and Engineering: A, vol. 485, no. 1-2, pp. 200-209, 2008.

[https://doi.org/10.1016/j.msea.2007.07.077]

-

N. A. Raji and O. O. Oluwole, “Recrystallization kinetics and microstructure evolution of annealed cold-drawn low-carbon steel,” Journal of Crystallization Process and Tech-nology, vol. 3, no. 4, pp. 163-169, 2013.

[https://doi.org/10.4236/jcpt.2013.34025]

-

T. Ogawa, H. Dannoshita, K. Maruoka, and K. Ushioda, “Microstructural evolution during cold rolling and subse-quent annealing in low-carbon steel with different initial mi-crostructures” Journal of Materials Engineering and Perfor-mance, vol. 26, no. 8, pp. 3821-3830, 2017.

[https://doi.org/10.1007/s11665-017-2849-6]

-

S. Dutta, A. K. Panda, A. Mitra, S. Chatterjee, and R. K. Roy, “Microstructural evolution, recovery and recrystalliza-tion kinetics of isothermally annealed ultra low carbon steel,” Materials Research Express, vol. 7, no. 1, p. 016554, 2020.

[https://doi.org/10.1088/2053-1591/ab657c]

-

J. Zhang, D. Raabe, and C. C. Tasan, “Designing duplex, ultrafine-grained Fe-Mn-Al-C steels by tuning phase trans-formation and recrystallization kinetics,” Acta Materialia, vol. 141, pp. 374-387, 2017.

[https://doi.org/10.1016/j.actamat.2017.09.026]

-

K. Jeong, S. -W. Jin, S. -G. Kang, J. -W. Park, H. -J. Jeong, S. -T. Hong, S. H. Cho, M. -J. Kim, and H. N. Han, “Ather-mally enhanced recrystallization kinetics of ultra-low car-bon steel via electric current treatment,” Acta Materialia, vol. 232, p. 117925, 2022.

[https://doi.org/10.1016/j.actamat.2022.117925]