Ammonia as a marine fuel: likelihood of ammonia releases

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

The maritime industry is transitioning to low or zero carbon fuels and ammonia is one of the potential substitutes for conventional fuels. For safe use of ammonia as a fuel, risk assessment is necessary to address the hazards presented by ammonia and to provide insights where experience as a fuel does not exist. Therefore, it is important to estimate the likelihood of ammonia releases is important. However, there is a lack of applicable leak data within the maritime industry. This study examines applicability of leak data from oil and gas industry by comparing the historical ammonia leak frequency recorded in the LPG tankers carrying ammonia with leak frequency estimate derived from the oil and gas data. The analysis shows that the oil and gas data provide a more conservative estimate than the historical leak frequency, concluding that the oil and gas data can be considered as a useful starting point for estimating the likelihood of ammonia releases. In addition, the ammonia leakage frequency of an ammonia-fuelled LPG carrier is estimated using the oil and gas leak database. The estimated frequency is approximately 0.054 per year, suggesting that the vessel could experience more than one ammonia leaks during operation.

Keywords:

Ammonia leakage, Ammonia leak frequency, Risk assessment, Ammonia-fuelled ships1. Introduction

The maritime industry is transitioning to low or zero carbon fuels as part of its efforts towards maritime decarbonisation. Ammonia is considered as one of the zero-carbon fuels with potential to replace conventional fossil fuels.

Since ammonia is gaseous under atmospheric conditions, ammonia- fuelled vessels are required to comply with the International Code of Safety for Ships Using Gases or Other Low-Flashpoint Fuels (IGF Code) [1]. Currently, the IGF Code does not provide prescriptive requirements to address the hazards presented by ammonia as fuel (e.g., its extreme toxicity). Therefore, a risk assessment is required to justify the safe use of ammonia as a fuel and to demonstrate that the IGF Code requirements have been met [1][2].

To conduct a successful risk assessment, an estimation of the likelihood of ammonia releases is necessary. This estimation is typically performed by using historical leak frequency data, however, there is no applicable leak frequency database in the maritime industry. As an alternative, utilising leak frequency databases from the oil and gas industry may be considered. However, the applicability of such data requires careful verification. This is because design codes, materials of construction, operational practices, the operating environment, management systems, and many other factors onboard vessels differ from those in oil and gas installations. Therefore, it is necessary to verify that the leak frequencies estimated for ships using the oil and gas data are broadly comparable with the recorded leak experience on ships before applying these databases to the maritime sector. Hence, this study derived the historical ammonia leak frequency by investigating ammonia leak incidents and comparing them with the leak frequency estimated from the oil and gas leak database to verify its applicability.

2. Ammonia Leak Incidents in Marine Industry

Ammonia has been transported by LPG tankers for decades. It is estimated that the world seaborne trade in ammonia is approximately 17.5 million tons annually [3] with most of it being transported using semi-refrigerated and fully refrigerated LPG (Liquefied Petroleum Gas) tankers that can carry ammonia as cargo. Historical ammonia leak events from those vessels could provide valuable information for estimating the frequency of ammonia leak events in ammonia-fuelled ships.

Various maritime accident databases, including the S&P Global Sea-web, IMO Global Integrated Shipping Information System (GISIS), Major Hazard Incident Data Service (MHIDAS), and internet news sources have been reviewed to investigate ammonia leak incidents on LPG tankers. Eight ammonia leak incidents were identified, and these are summarised in Table 1. As noted in Table 1, the sources of ammonia leaks in the eight incidents included: hose leakage; loading arm leakage; valve mis-operation; pipe leakage; and gasket leakage. In total, these incidents resulted in 9 fatalities and 15 injuries owing to ammonia exposure. No ignition was reported in any of the incidents. The majority of these incidents occurred during cargo operations, with ammonia contained in the cargo piping system, rather than during sea going operations where ammonia was stored in the cargo tanks.

It should be noted that the limited number of reported incidents may not comprehensively reflect the actual number of ammonia leak incidents. This is because certain incidents involving minor leaks may not have been reported or captured in the databases and sources searched.

3. Historical Marine Ammonia Leak Frequency

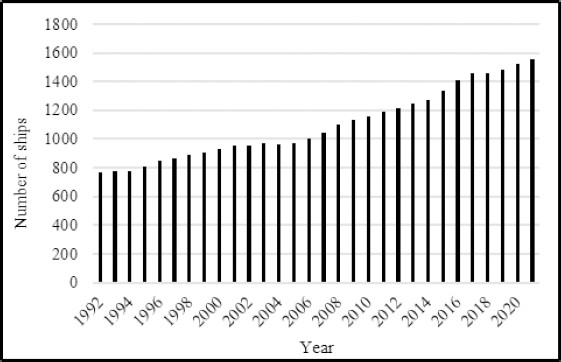

For the calculation of the historical leak frequency, the population of LPG tankers used for ammonia transportation is necessary. This data is derived from the global LPG tanker fleet, as depicted in Figure 1 [4], and the historical ammonia cargo employment ratios for LPG tankers [9] listed below:

- • 1992-2021: 12%

- • 1992-2001: 14%

- • 2002-2011: 15%

- • 2012-2021 :9%

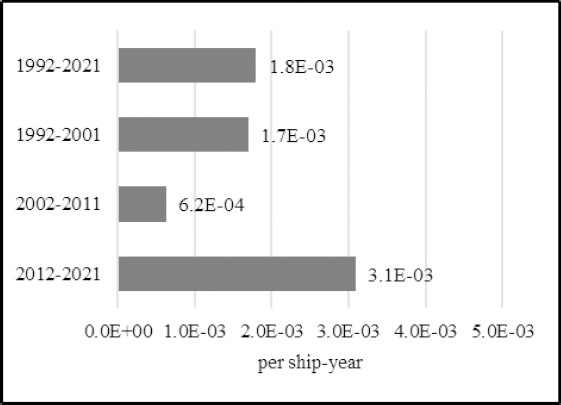

The historical frequencies of ammonia leaks from LPG tankers have been calculated by dividing the number of leak incidents in a specific time period by the number of the LPG tankers at risk during that period. The leak frequency estimates, shown in Figure 2, are calculated for four time periods: 2012–2021, 2002–2011, 1992–2001 and 1992–2021. The estimated frequency for 2012–2021 was 0.0031 per year (3.1E-03/year), that for 2002–2011 was 0.00062 per year (6.2E-04/year), and that for 1992–2001 was 0.0017 per year (1.7E-03/year). The estimated frequency for the last 30 years, that is from 1992 to 2021, is 0.0018 per year (1.8E-03/year).

Notably, to avoid stress corrosion cracking, special requirements for ammonia as cargo entered into force within the IGC Code on 1 July 1994; introducing specific material selection for cargo tanks, process pressure vessels and piping [10]. Therefore, it is considered reasonable to use the historical data for LPG tankers built after 1994 to estimate the leak frequency of ammonia-fuelled ships, recognising that the material selection and piping design requirements for ammonia-fuelled ships are similar to those required by the IGC Code [11][12]. Consequently, it was considered appropriate to use data from the most recent decade to account for LPG tankers built after 1994. Furthermore, this approach provides a more reasonable estimate of leak frequency, particularly considering the advancements in information technology that have improved the incident reporting systems.

To verify the estimates obtained above, a comparison was made with the frequency estimated in a study by Baldock of accidental ammonia releases [13]. This study showed that the historical estimation above (3.1E-03/year) is comparable to the estimate of Baldock (5.0E-03/year). However, the frequency estimates in both studies were based on a limited number of reported incidents, and the accuracy of the estimates depends on the details of the underlying data. Whilst the historical data provides a useful starting point for estimating the leak frequencies for ammonia, caution should be exercised when interpreting the results, and further research and data collection would improve confidence in leak frequency estimates.

4.Ammonia Leak Frequency Estimation using Oil and Gas Leak Database

Amongst the numerous leak frequency databases in the oil and gas industry, that published by the International Association of Oil & Gas Producers (IOGP) [14] is considered one of the most reliable sources. This IOGP database is based on an analysis of the UK Health and Safety Executive’s hydrocarbon release database (HCRD) for 1991-2015 and covers offshore process leaks in the UK. From a review of the listed components, it is considered here that the IOGP database provides release frequencies from equipment types that are similar to the fuel systems proposed for ammonia as fuel, such as stee pipes, flanged joints, valves, pumps and compressors.

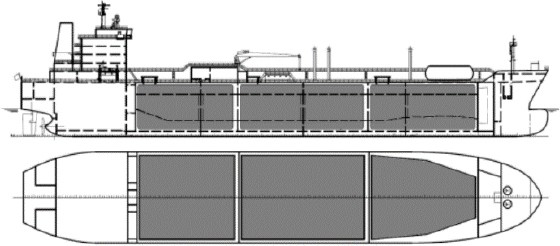

Using the IOGP database, the likelihood of ammonia releases was calculated from a representative LPG tanker to examine the feasibility of using oil and gas leak frequency databases for ammonia leakage frequency estimation. A so called “handy-sized” fully refrigerated LPG carrier, shown in Figure 3, was selected to represent LPG tankers carrying ammonia, assuming that the vessel has the following specifications:

- • 23,000 m3 class LPG tanker

- • three independent cargo tanks of IMO type A with a complete secondary barrier, containing cargo in a fully refrigerated condition at or near atmospheric pressure

- • three reliquefication units for cargo tank pressure control

- • Two liquid and two vapour crossovers in the cargo handling system

The cargo handling system of the vessel was divided into smaller segments by the location and for each segment the leak frequencies were estimated by undertaking a part-count and applying the leak frequency data within the IOGP database. As an example, Table 2 presents the part count result for the reliquefaction unit segment, which includes the equipment in the cargo compressor room, such as cargo compressors, cargo condensers and associated piping system.

For the overall ammonia release frequency estimation of the vessel, the ratios of operating modes and utilisation of the equipment were assumed as follows:

- • Ratio of operating modes:

o Transit/manoeuvring: 75%

o Waiting: 5%

o Loading and unloading: 20% - • Reliquefaction unit utilisation (2 units running):

o 30% during transit, manoeuvring and waiting

These assumptions are derived from the author’s analysis of the operating patterns of LPG tankers dedicated to ammonia trading, the operating profile information provided by an LPG tanker operator, and the daily running time calculation of the reliquefaction unit.

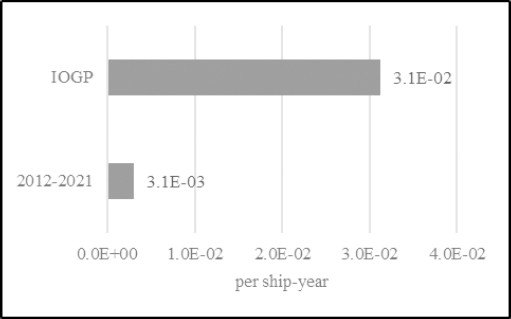

The estimated ammonia release frequency for the representative LPG tanker is summarised in Table 3. The overall release frequency was calculated as 0.031 per year (3.1E-02/year), which approximates to one ammonia leak event every 32 years, implying that one ammonia leak event might be expected in the lifetime of an LPG tanker that carrying ammonia.

5. Comparison of Ammonia Leak Frequencies

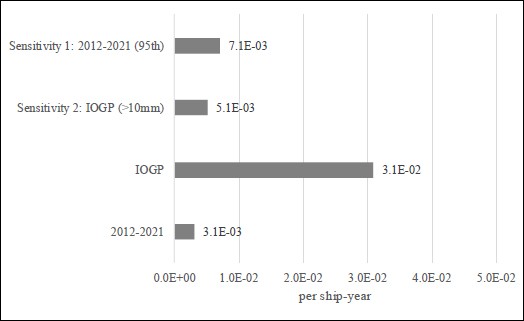

The ammonia leak frequencies derived from the historical incident records and those calculated from the IOGP database are presented in Figure 4. It can be noted that the ammonia leak frequency obtained from the IOGP data (3.1E-02/year) is approximately ten times greater than the historical ammonia leak frequency derived from the ammonia leak incident records in 2012–2021.

As stated earlier in this study, it should be noted that the limited number of reported incidents might not be a comprehensive reflection of the actual number of ammonia leak incidents, as certain incidents may not have been reported or captured in the databases and sources searched. To help address this, the following sensitivity cases were considered:

- • Historical ammonia leak frequency estimation at upper 90% confidence interval limit; and,

- • Leak frequency calculation using only leak diameters above 10 mm.

With hypothesis that the occurrence of releases follows a Poisson distribution and system configuration of the LPG tankers are identical, the leak frequency estimation at the upper 90% is expressed as Equation (1):

| (1) |

where λ is event frequency and x is the number of observed events during the time of t [15]. From the equation, the leak frequency was estimated as 0.0071 per year (7.1E-03/year) for 2012–2021 period. Even though a 90% confidence limit value was taken into account, the leak frequency estimation provided by the IOGP (3.1E-02/year) remained conservative.

Assuming that small leaks with insignificant consequences are not reported, then the release frequency for leak diameters greater than 10mm diameter can be considered. The total release frequency for holes exceeding 10 mm diameter was estimated to be 0.0051 per year (5.1E-03/year) as summarised in Table 4. This result further supports the conservative nature of the IOGP data.

The ammonia leak frequencies of the sensitivity cases, historical leak frequency (2012-2021), and leak frequency estimation using IOGP are shown in Figure 5. This comparison indicates that estimating the frequency of ammonia leaks using the oil and gas leak database involves a conservative approach. Consequently, the use of these databases would not lead to an underestimation of the risk associated with ammonia leakage. Thus, it could be considered appropriate to utilise them as a starting point for leak frequency estimation.

6.Ammonia Leak Frequency Estimation for an Ammonia-Fuelled Ship

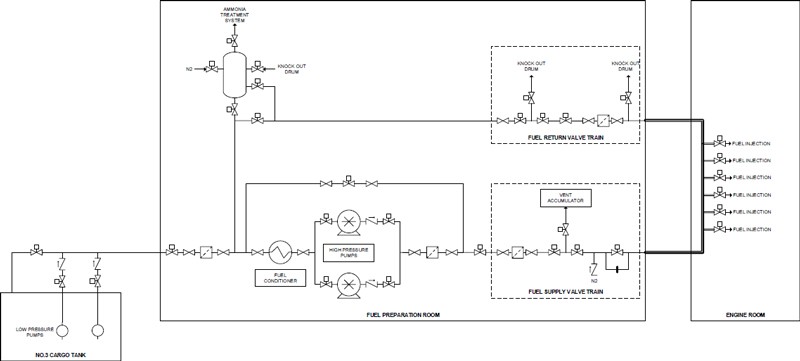

After examining the applicability of oil and gas leak database to LPG tankers carrying ammonia as cargo, the ammonia leak frequency of an ammonia-fuelled LPG carrier was estimated using the same database as an example. It was assumed that the representative LPG tank is equipped with an ammonia fuel supply system shown in Figure 6, which supplies ammonia fuel to the main engine. The ammonia fuel supply system is briefly described as follows:

- • Ammonia stored in the no.3 cargo tank is used as fuel

- • One of the two low-pressure pumps installed in the no.3 cargo tank delivers ammonia to the ammonia fuel supply system located in the fuel preparation room.

- • The fuel preparation room contains two high-pressure pumps (2 × 100%), one fuel conditioner, one ammonia catch tank, a fuel supply valve train, a fuel return valve train, an engine knock-out drum, and an ammonia treatment system.

- • The fuel supply and return lines to the main engine are made of double walled pipes.

- • Flanged connections are minimised as much as possible.

Table 5 shows the leak frequency of the ammonia fuel supply system, which was calculated by counting the number of components comprising the fuel supply system and applying the IOGP release frequency data. For the double-walled pipes, leak frequencies were assumed to be reduced by factors of 100, 75, and 10 for leak hole diameters of 1–3 mm, 3–10 mm and 10 mm– full-bore respectively [16].

The estimation results showed that the fuel preparation room has the highest probability of experiencing a leak, once in 34 ship-year (2.6E-02/year). This could be compounded if the fuel supply system is installed in the cargo compressor room where the reliquefaction units are located, considering the high leak frequency of the reliquefaction compressors.

The leak frequency of the ammonia fuel supply system was added to that of the conventional LPG tanker, addressed in Table 3, in order to estimate the overall leak frequency of the ammoniafuelled LPG tanker. As presented in Table 6, the overall ammonia leak frequency of the ammonia-fuelled-LPG tanker was approximately 0.054 per year (5.4E-02/year), suggesting that an ammonia leak is expected once every 18 years on such a ship. The overall leak frequency indicated a 74 percent increase compared to that of the representative LPG tanker using conventional fuel. Furthermore, the likelihood of an ammonia release could be much higher if the generator engines and boilers of the vessel also use ammonia fuel.

Based on this estimate, it can be expected that, on average, an ammonia-fuelled LPG tanker, particularly one carrying ammonia as cargo, would experience more than one ammonia leak during its operational lifetime. Therefore, to mitigate the risks associated with ammonia release, it is crucial to implement meaningful safeguards against ammonia leaks on these vessels.

7. Conclusion

Estimation of the likelihood of ammonia releases is important for conducting a successful risk assessment for ammonia-fuelled ships. However, there is no applicable leak frequency database in the maritime industry. As an alternative, utilising leak frequency databases from the oil and gas industry may be considered. However, to ensure an appropriate estimation, it is necessary to verify that the overall leak frequency estimated using the oil and gas data is broadly comparable with the recorded experience of ships.

From the analysis of ammonia release incidents experienced by the LPG tankers carrying ammonia, and the comparison with the ammonia leak frequency estimate using the oil and gas leak data, it was concluded that the oil and gas leak data provides a useful starting point for estimating the likelihood of ammonia releases from ships.

Furthermore, as an example, the ammonia leakage frequency for an ammonia-fuelled LPG carrier is estimated using the oil and gas leakage data. The frequency is approximately 0.054 per year (5.4E-02/year), suggesting that, on average, the vessel could experience one or two ammonia leaks during its operation. This highlights the necessity of implementing meaningful safeguards against ammonia leaks to mitigate the risks associated with the ammonia release on the vessels.

A notable limitation of this study is the potential incompleteness of the historical ammonia leak incidents, which stems from lack of a robust incident reporting system in the maritime industry. To further verify and validate the applicability of oil and gas leak database, continuous monitoring of leak incidents associated with low flashpoint fuels, including ammonia, onboard ships is necessary. This should be complemented by periodic comparisons with the estimates provided by the oil and gas databases. A scaling factor may be considered if the recorded experience does not align with the database.

Acknowledgments

This paper is a revised and expanded version of a paper entitled ‘Research on ammonia leakage incidents and ammonia leakage frequency estimate in risk assessment’ presented at the 2023 Joint Academic Conference of the Korean Association of Ocean Science and Technology Societies.

Author Contributions

Conceptualization, K.T. Moon; Methodology, K.T. Moon; Formal Analysis, K.T. Moon; Investigation, K.T. Moon; Writing— Original Draft Preparation, K.T. Moon; Writing—Review & Editing, P. Davies, and L. Wright; Supervision, P. Davies, and L. Wright;

References

- International Maritime Organization, International Code of Safety for Ships Using Gases or Other Low-Flashpoint Fuels, 2017.

- International Maritime Organization, Guidelines for the Approval of Alternatives and Equivalents as Provided for in Various IMO Instruments, MSC.1/Circular.1455, 2013.

- Alfa Laval, Hafnia, Haldor Topsoe, Vestas, and Siemens Gamesa, Ammonfuel - An Industrial View of Ammonia as a Marine Fuel, Hafnia, Aug. 2020. [Online]. Available: https://www.topsoe.com/hubfs/DOWNLOADS/DOWNLOADS%20-%20White%20papers/Ammonfuel%20Report%20Version%2009.9%20August%203_update.pdf, , Accessed May. 2, 2023.

- S&P global, Sea-Web, https://maritime.ihs.com/Seaweb/, , Accessed May 2, 2023.

- UK HSE, Major Hazard Incident Data Service (MHIDAS), 1999.

- Sale-ships.com, Ammonia leakage from LPG Carrier Al Marona, https://sale-ships.com/ammonia-leakage-lpg-carrier-almarona/, , 2012, Accessed May 2, 2023.

- Mikhail Voytenko, Poisonous cloud of ammonia leaked from LPG tanker Gas Columbia, Ukraine. https://www.fleetmon.com/maritime-news/2013/2438/poisonous-cloud-ammonia-leaked-lpg-tanker-gas-colu/, , 2013, Accessed May 2, 2023.

- Mikhail Voytenko, Anhydrous ammonia leak from LPG tanker Sombeke, Houston. https://www.fleetmon.com/maritime-news/2014/4234/anhydrous-ammonia-leak-lpg-tanker-sombeke-houston/, , 2014, Accessed May 2, 2023.

-

MSI, LPG Carrier Maker Outlook Q2 2022, 2022.

[https://doi.org/10.1016/j.fopow.2022.07.008]

- International Maritime Organization, Adoption of Amendments to the International Code for the Construction and Equipment of Ships Carrying Liquefied Gases In Bulk (IGC Code), MSC.30(61), 1992.

- Lloyd’s Register, Rules and Regulations for the Classification of Ships using Gases or other Low-flashpoint Fuels, Appendix LR2, 2023.

- International Maritime Organization, International Code for the Construction and Equipment of Ships Carrying Liquefied Gases in Bulk, 2014.

- P. J. Baldock, “Accidental releases of ammonia: An analysis of reported incidents,” In American Institute of Chemical Engineers Loss Prevention Meeting, pp. 1-5, 1979.

- International Association of Oil & Gas Producers, Risk Assessment Data Directory: Process Release Frequencies, Report No. 434 – 1, 2019.

- Sandia National Laboratories, Handbook of Parameter Estimation for Probabilistic Risk Assessment, NUREG/CR-6823, 2003.

- P. Davies and E. Fort, “LNG as a marine fuel: Likelihood of LNG releases,” Journal of Marine Engineering and Technology, vol. 12, no. 3, pp. 3-10, 2013.