Effect of powder preform consolidation process on the microstructure and extrusion behavior of miniature helical gears for gas-atomized Zn-22wt%Al powder

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Powder extrusion experiments were performed to demonstrate the microstructure transition and extrusion behavior of miniature helical gears from different consolidation processes for gas-atomized (GA) Zn-22wt%Al powder before extrusion. The compacted powder preforms were consolidated by solution heat treatment, sintering, and dwell quenching. Scanning electron microscope (SEM) images revealed three different microstructures: fine equiaxed grain structures, lamellar structures, and mixed structures. Extrusion experiments were performed at 250 °C with a strain rate of 2.36×10-3s-1. The configurations of the miniature helical gear were 0.3 in the module, 15° in the helix angle, and 12 in the number of teeth. The microstructures and extrusion behavior of the helical gears were estimated using SEM measurement of extrusion load, and Vickers hardness tests. The Zn-22wt%Al green compact with a fine equiaxed grain structure provided the lowest extrusion load and highest Vickers hardness owing to the superplastic deformation behavior.

Keywords:

Powder consolidation, Extrusion, Gas-atomized Zn-22wt%Al powder, Miniature helical gear1. Introduction

Powder extrusion is the current powder metallurgy manufacturing process employed to produce fully dense materials with improved performance [1]. Its main advantage over other processes, such as hot forming and hot isostatic pressing, is derived from the high shearing stresses, which result in excellent mechanical properties [2]-[4]. In the traditional powder extrusion process, a high force may be required to produce complex-shaped components, even at high temperatures.

Zn-22wt%Al alloy is a classic material that is widely used in the automobile and textile industries. Materials with very fine grain sizes can exhibit high elongation at low forming forces when formed at moderate temperatures and specific strains [5]-[7]. Several experimental studies have investigated the superplastic deformation behavior of Zn-22wt%Al alloys. Yeh and Chang reported that a fine-grained Zn-22wt%Al eutectoid alloy possessed excellent forge ability at 200 °C with a compressive strain rate of 0.6 s-1 [8]. The lamellar structure of Zn-22wt%Al was transformed into a fine equiaxed grain structure via heat treatment and extrusion, and the alloy exhibited superplastic flow characteristics, as summarized by Mohamed et al. [9]. Powder consolidation is an important step in the development of a controlled microstructure after powder manufacturing techniques in the powder metallurgy pathway [10].

The main objective of this study is to investigate the effect of powder preform consolidation processes before extrusion on the microstructure of extruded helical gears and the deformation behavior of gas-atomized (GA) Zn-22wt%Al alloy powder. Compacted powder billets are consolidated by solution heat treatment, sintering, or dwelling-quenching, and are then extruded. The resulting microstructure, forming load, and Vickers hardness of the fabricated helical gear are evaluated.

2. Experimental procedure

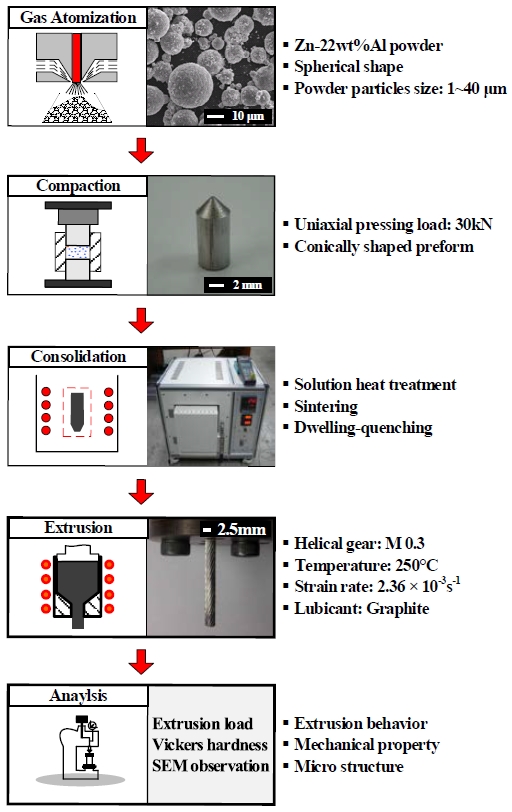

Figure 1 shows the powder extrusion process sequence for fabricating miniature helical gears. Owing to its superplastic deformation behavior, GA Zn-22wt%Al powder was adopted as the billet material for the extrusion of the helical gear. A conically shaped specimen of size D4.9×h14 mm was pressed at a compressive force of 30 kN. The compacted samples were consolidated using different processes, such as solution heat treatment, sintering, and dwelling-quenching. After consolidation, the samples were extruded under superplastic-forming (SPF) conditions. The effects of the consolidation process before extrusion on the microstructure of extruded helical gears and their deformation behavior were investigated using Vickers hardness distributions and extrusion load measurements, as well as scanning electron microscopy (SEM) observations.

2.1 Conditions of powder preform consolidation

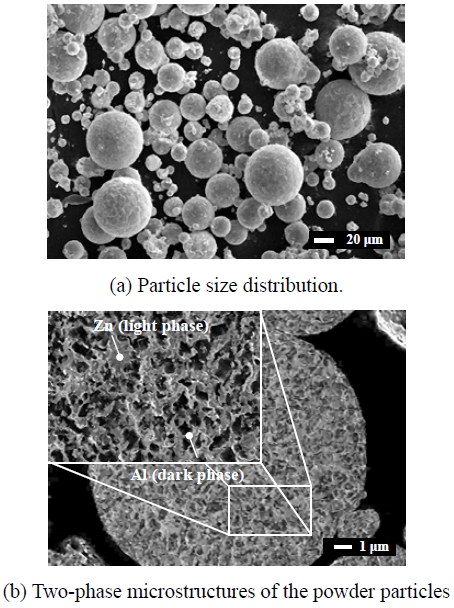

Figure 2 shows the SEM images of the GA Zn-22wt%Al powders, which contained spherical particles of various sizes below 40 μm. The microstructure of the powder used to manufacture miniature helical gears exhibited a fine two-phase structure. The light and dark phases are Zn and Al, respectively [9][11].

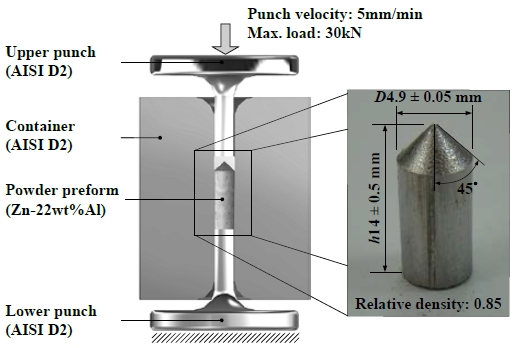

The compaction equipment and the appearance of the powder preform are shown in Figure 3. The alloy powders were compacted into a conical shape (D4.9×h14 mm) under a compressive force of 30 kN; the relative density of the compacted specimens was reported to be approximately 0.85 in the previous study [11].

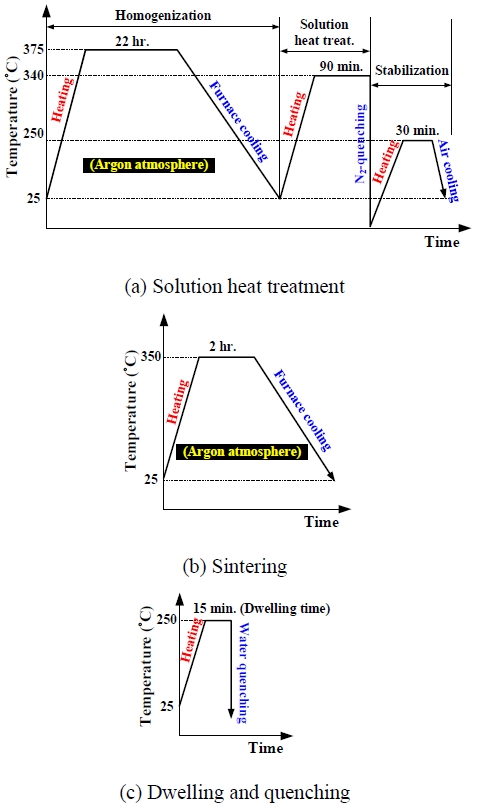

Subsequently, the specimens were consolidated using the three processes shown in Figure 4. First, the compacted powders were homogenized at 375 °C for 22 h, solution heat treated at 340 °C for 90 min, quenched in liquid nitrogen, and stabilized at 250 °C for 30 min (Figure 4(a)). Second, the specimens were sintered at 350 °C for 2 h and then cooled in a furnace (Figure 4(b)). Third, the specimens were heated and stabilized at 250 °C for 15 min and then quenched in water (Figure 4(c)) to improve the formability of mechanically alloyed (MA) Zn-22wt%Al powder [12]. The microstructures of the consolidated specimens were investigated using SEM.

2.2 Conditions of extrusion process

Extrusion experiments with consolidated powder preforms were performed to evaluate the effects of different microstructures on the extrusion behavior and mechanical properties of helical gears in a hot-powder extrusion process.

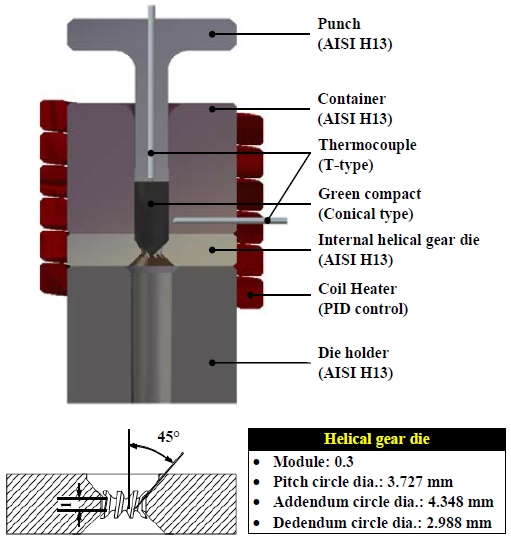

Figure 5 shows the configuration of the helical gear die and extrusion equipment used in this study. The specifications of the helical gears were a pitch diameter of 3.727 mm, 12 number of teeth, module of 0.3, reduction ratio of 50%, and helix angle of 15°. AISI H13 was used for the extrusion die.

The temperature and strain rate in hot extrusion are the most important parameters that influence the deformation behavior of the powders. Extrusion temperature of 250 °C and punch speed of 0.1 mm/min under an average strain rate of 2.36×10-3s-1 were hot working conditions for superplastic deformation behavior [13].

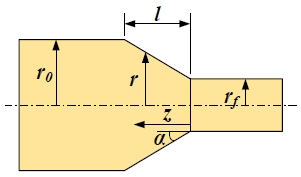

Figure 6 shows the symbols used to calculate the average strain rate. In forward extrusion, the strain rate is defined by Equation (1).

| (1) |

The average strain rate inside the extrusion die was obtained by averaging the volume in Equation (1). The volume of the deformation region between the die inlet and outlet is equal to Equation (2).

| (2) |

The above average strain rate is given by Equation (3):

| (3) |

where v0 denotes the extrusion velocity, α denotes the half-die angle, and R denotes the extrusion ratio. r0 and rf are the radii of the powder preform and the helical gear, respectively.

The microstructure of powder preforms is a significant parameter that influences the forming behaviors [8][9]. To determine the optimal microstructures of the Zn-22wt%Al powder billet, it was extruded from various microstructures obtained via three different consolidation processes. During powder extrusion, a graphite lubricant (Klüber Press DC5-01KR) was applied to the extrusion tool, and a green compact was used to prevent adhesion. Extrusion experiments were carried out at MTS (100 kN), and the billet temperature (250 °C) in the container was directly measured using a contact-type T-type thermocouple. The general conditions of powder extrusion are listed in Table 1.

3. Results and discussion

3.1 Results of powder preform consolidation

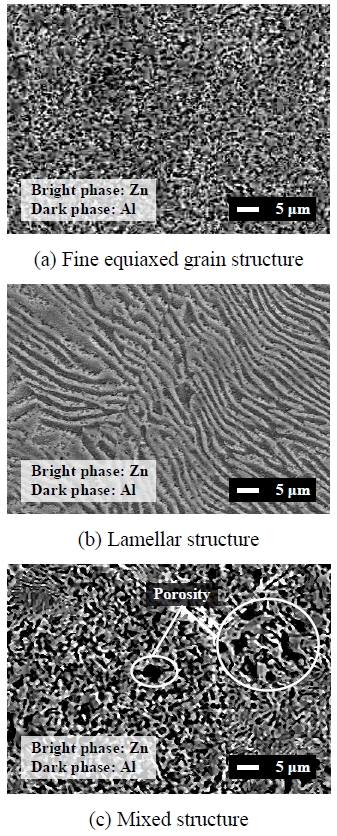

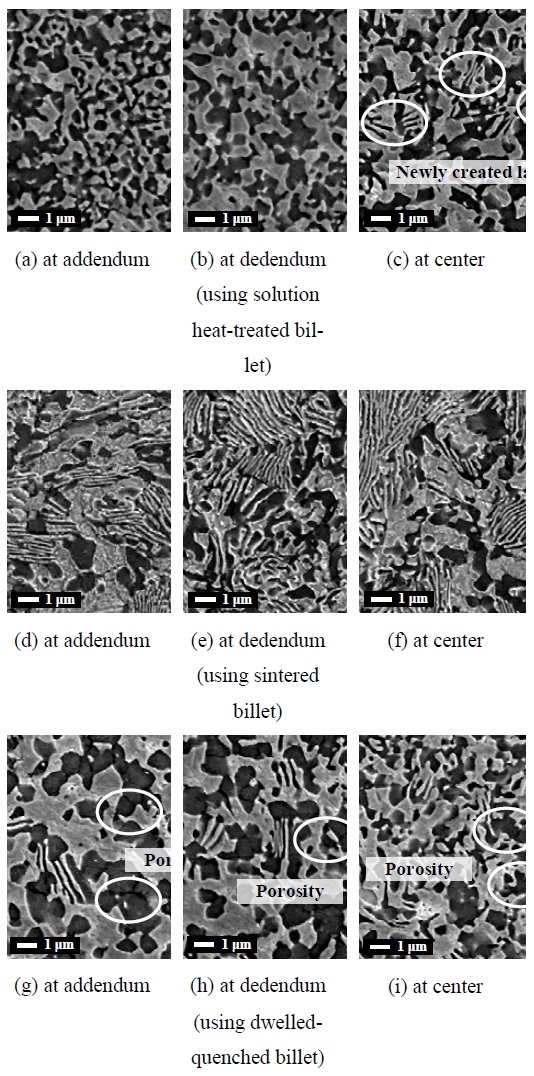

Figure 7 shows the microstructures of the powder billets consolidated by various processes. The SEM micrographs of the consolidated billets revealed three different microstructures. As shown in Figure 7(a), the solution heat treatment result in a very fine equiaxed grain structure with a Vickers hardness of 67.1 (Hv. 100 gf). The microstructure of the sintered billets was a typical lamellar eutectoid structure with a 63.3 Hv. The thicknesses of the individual layers were 1-2 μm, as shown in Figure 7(b). A mixed structure, with lamellar and equiaxed grain structures, was obtained via dwelling and quenching processes. The final consolidation process provided internal porosity. In all SEM micrographs, the bright phase was Zn and the dark phase was Al [9].

3.2 Results of extrusion process

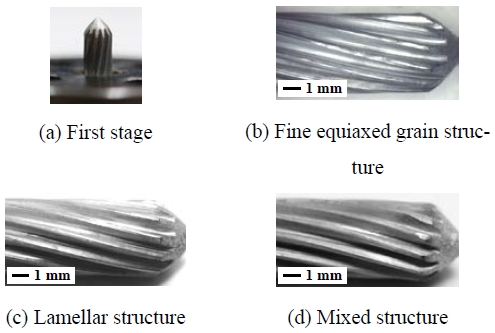

Figure 8 shows the surfaces of the helical gears with different consolidated billets (fine equiaxed grain, lamellar, and mixed structures). The surfaces of the gear teeth were fine, and no surface defects were observed during the extrusion process.

The microstructure of Zn-22wt%Al alloys has a considerable influence on the SPF. The three basic requirements for SPF are (i) a temperature higher than approximately one-half of the melting temperature, Tm, (ii) a strain rate less than 10-2 s-1, and (iii) a fine and equiaxed grain size (<10 μm), which did not undergo significant grain growth during deformation. The conditions for the extrusion experiments fundamentally satisfy requirements (a) and (b).

Figure 9 shows the typical microstructures of the extruded Zn-22wt%Al specimens from different consolidated billets. The microstructure was finer, but substantially unchanged from that of the initially consolidated billets. A fine equiaxed grain structure was maintained during the extrusion process, and no microcracks were observed in the cross-sections of the extruded helical gears. These results might be attributed to the grain boundary sliding and diffusion creep mechanism, which play an important role in the fine-grained Zn-22wt%Al eutectoid alloy during the forming process under compression stress states [8]. The microstructure changed from a mixed to a fine equiaxed grain structure when the extrusion experiments were dwelled and quenched. However, there were some microcracks and pores in the case of the dwelled and quenched billets.

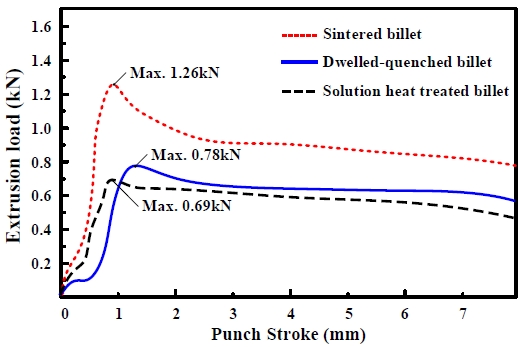

Figure 10 shows the extrusion load-punch stroke curves of the Zn-22wt%Al alloy prepared using different consolidation processes. The powder preforms were extruded into elongated gear shapes after reaching their maximum extrusion load. The extrusion load of the lamellar Zn-22wt%Al alloy was dramatically higher than that of the fine equiaxed-grained Zn-22wt%Al alloy under the same extrusion conditions. A greater extrusion load (> 1.2 kN) was required for specimens with lamellar structures resulting from sintering, and a drop in the extrusion load was observed after a certain punch stroke. Consequently, a higher deformation energy is required to fill the fine teeth of the helical gear during extrusion compared with forming using the fine equiaxed-grained Zn-22wt%Al alloy preform [11]. The maximum extrusion load with the fine equiaxed grain structure resulting from solution heat treatment was only 0.69 kN, and the extrusion load curve was quite flat throughout the whole extrusion process. This illustrates that a fine equiaxed microstructure of Zn-22wt%Al alloys leads to a forming load lower than 60%, which is a typical superplastic flow.

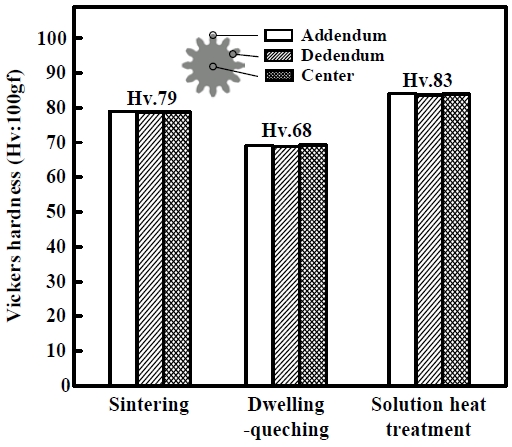

The Vickers hardness (Hv. 100gf) of the deformed helical gears is shown in Figure 11. The hardness was measured at three different points on the cross-section of the helical gears. The distribution of hardness was uniform over all measured points for individual cases. Despite the lowest extrusion load, the fine-grained billet obtained by solution heat treatment provided a greater hardness, about 83 Hv, after extrusion. However, owing to the residual porosity, cracks, and relatively large grain size in the mixed structure, a lower hardness (approximately 68 Hv) resulted in the extruded gear.

4. Conclusions

To investigate the effects of consolidation processes before extrusion on the microstructure and deformation behavior of miniature helical gears for GA Zn-22wt%Al powder, extrusion experiments were performed using three different consolidation processes. The results are summarized as follows:

- (1) Among the consolidation processes of the Zn-22wt%Al powders, the solution heat treatment provided a very fine equiaxed grain structure, the sintering process led to a lamellar structure, and a mixed structure was obtained via the dwelling-quenching process.

- (2) The fabricated miniature helical gears had no surface defects. The initial microstructure of the consolidated billets was almost unchanged after extrusion but was finer. However, in the case of the dwelled and quenched billets, the microstructure changed from a mixed to a fine equiaxed grain structure.

- (3) The fine, equiaxed microstructure of the Zn-22wt%Al alloy obtained by solution heat treatment led to a lower forming load (0.69 kN) and higher hardness (83 Hv) by superplastic deformation behavior.

Acknowledgments

This research was supported by Korea Basic Science Institute (National Research Facilities and Equipment Center) grant funded by the Ministry of Education (grant No. 2022R1A6C101B738).

Author Contributions

Conceptualization, I.-K. Lee and K.-H. Lee; Methodology, S.-K. Lee and K.-H. Lee; Experiment, I.-K. Lee and K.-H. Lee; Validation, S.-K. Lee and K.-H. Lee; Investigation, I.-K. Lee; Data Curation, I.-K. Lee and K.-H. Lee; Writing—Original Draft Preparation, I.-K. Lee; Writing—Review & Editing, K.-H. Lee; Supervision, K.-H. Lee.

References

-

Z. Y. Ma, X. G. Ning, Y. X. Lu, J. Bi, and et al., “In-situ Al4C3 dispersoid and SiC particle mixture-reinforced aluminum composite,” Scripta Metallurgica et Materialia, vol. 31, no. 2, pp. 131-135, 1994.

[https://doi.org/10.1016/0956-716X(94)90163-5]

-

J. R. Pickens, “Aluminum powder metallurgy technology for high-strength applications,” Journal of Materials Science, vol. 16, no. 6, pp. 1437-1457, 1981.

[https://doi.org/10.1007/BF02396863]

-

Y. W. Kim, W. M. Griffith, and F. H. Froes, “Surface oxides in P/M aluminum alloys,” Journal of Metals, vol. 37, no. 8, pp. 27-33, 1985.

[https://doi.org/10.1007/BF03257675]

-

E. J. Lavernia, J. D. Ayers, and T. S. Srivatsan, “Rapid solidification processing with specific application to aluminum alloys,” International Materials Reviews, vol. 37, no. 1, pp. 1-44, 1992.

[https://doi.org/10.1179/imr.1992.37.1.1]

-

K. Tully and J. Monaghan, “Bulk forming of superplastic alloys,” Journal of Materials Processing Technology, vol. 26, no. 2, pp. 159-171, 1991.

[https://doi.org/10.1016/0924-0136(91)90130-7]

-

J. M. Monaghan and K. Tully, “The production of forming dies by hobbing superplastic materials,” Journal of Materials Processing Technology, vol. 26, no. 3, pp. 281-295, 1991.

[https://doi.org/10.1016/0924-0136(91)90064-L]

-

M. C. Somani, R. Sundaresan, O. A. Kaibyshev, and A. G. Ermatchenko, “Deformation processing in superplasticity regime production of aircraft engine compressor discs out of titanium alloys,” Materials Science and Engineering: A, vol. 243, no. 1-2, pp. 134-139, 1998.

[https://doi.org/10.1016/S0921-5093(97)00790-9]

-

M. S. Yeh and C. B. Chang, “Microstructure effects on the forgeability of Zn-22Al eutectoid alloy,” Journal of Materials Engineering and Performance, vol. 11, no. 1, pp. 71-74, 2002.

[https://doi.org/10.1007/s11665-002-0010-6]

-

Y. Xun and F. A. Mohamed, “Microstructure and deformation in the spray deposited Zn-22% Al alloy,” Material Science and Engineering: A, vol. 432, no. 1-2, pp. 261-268, 2006.

[https://doi.org/10.1016/j.msea.2006.06.019]

- E. Klar, Metals Handbook, 9th Edition(Vol.7 Powder Metallurgy), Cleveland, USA, 1984.

-

K. H. Lee, J. M. Lee, J. H. Park, and B. M. Kim, “Fabrication of miniature helical gears by powder extrusion using gas atomized Zn-22wt%Al powder,” Transactions of Nonferrous Metals Society of China, vol. 22, no. 6, pp. 1313-1321, 2012.

[https://doi.org/10.1016/S1003-6326(11)61320-4]

- K. H. Lee, D. W. Hwang, K. H. Ruy, and B.M. Kim, “Hybrid powder extrusion process for improvement on formability of MA Zn-22wt% Al powder,” Steel Research International, vol. 81, no. 9, pp. 1316-1319, 2010.

-

Y. Saotome and H. Iwazaki, “Superplastic extrusion of microgear shaft of 10 μm module,” Microsystem Technologies, vol. 6, no. 4, pp. 126-129, 2000.

[https://doi.org/10.1007/s005420050180]