Evaluation of impact resistance and material properties of eco-friendly buoys with biodegradable plastic materials

Copyright ⓒ The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Different eco-friendly buoys composed of materials, such as Polyethylene (PE), Polypropylene (PP), polyethylene terephthalate(PET), are used as a countermeasure for marine pollution issues of Styrofoam buoys. However, fragmented microplastics continue to persist without fundamental material conversion. Currently, the most commonly used eco-friendly buoy is composed of thermoplastic, which adversely affects the seawater ecosystem owing to the generation of refractory plastic. To address this issue, in this study, a biodegradable material was developed for buoys that minimizes the generation of microplastics, and a material property test based on ASTM D638 was conducted to determine the strength of the biodegradable material. In addition, to evaluate the impact-resistance performance satisfaction of buoys specified in the eco-friendly buoy certification standard, the optimal thickness of eco-friendly buoys was estimated by generating a buoy model, applying the physical properties of development materials and analyzing the impact through the free drop of the EPP.

Keywords:

Eco-friendly buoys, Biodegradable plastic material, Microplastics, Material properties test, Finite element method, Impact analysis1. Introduction

Recently, the risk of microplastics has emerged as an issue in domestic and international communities. In Korea, buoys composed of polystyrene (EPS), which are used as aquaculture buoys, are considered the primary source of microplastics [1]. Occasionally, polystyrene (EPS) buoys disappear owing to natural disasters, such as ship collisions and typhoons. However, they are discarded in the sea because of management negligence or speculation [2].

Therefore, fish-farming buoys are currently being collected by local governments and fishermen in connection with eco-friendly buoy supply projects by collecting beach waste or returning existing EPS (polystyrene) buoys. Furthermore, eco-friendly buoys, such as those composed of PE, PP, and PET, are being distributed. However, fragmented microplastics persist without fundamental material conversion. Microplastics generated in the ocean are shown in Figure 1.

Therefore, in this study, to develop biodegradable plastic materials, the optimal thickness was selected using the material property tests and simulation parameter studies for buoys [3][4].

2. Material test

2.1 Experimental method

The deformation behavior of plastic can be described based on the connection state of the molecular chain.

As the molecular chain entangled by the external load is released, a yield stress appears along with nonlinear elastic behavior. Afterward, a softening behavior is observed, and then, a hardening behavior emerges owing to the locally released molecular chain, which leads to rupture [5].

Generally, plastic materials exhibit different von Mises stresses, depending on the deformation mode in which pressure is applied, and pressure significantly affects the yield condition. Therefore, material data for short-axis, shear, compression, and biaxial tensile tests are required to obtain accurate mechanical properties of plastic materials.

However, in the case of the developed biodegradable material, the purpose of material test is to obtain physical properties for simulation, and it is limited to conduct various tests of the material. Therefore, this study obtained a stress-strain curve through a tensile test.

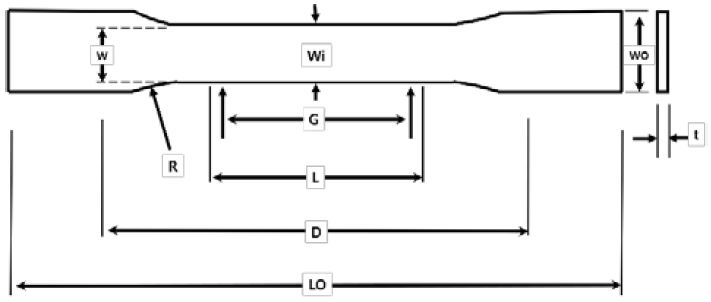

The tensile test was performed based on the ASTM D638 standard test method for the tension properties of plastic specifications. The test speed was 5 mm/min. The dimensions of the specimens are presented in detail in Figure 2 and Table 1 [6].

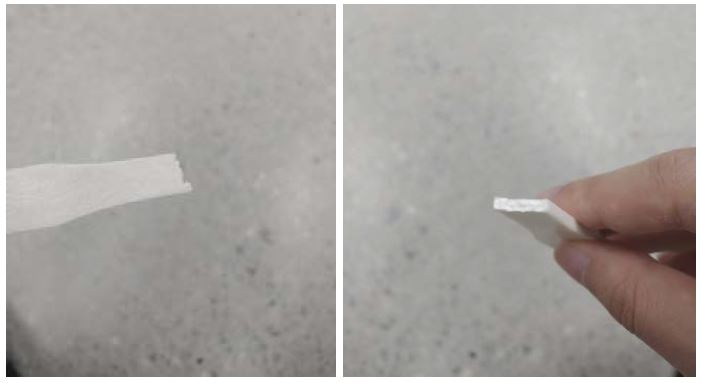

The specimens used in the tests are shown in Figure 3. The specimen used in the test is composed of poly lactic acid (PLA) material. PLA is a representative plastic material composed of processed lactic acid obtained by fermenting and refining the glucose extracted from corn. It is an eco-friendly biodegradable material that naturally decomposes into water and carbon dioxide within a few months because of the action of microorganisms under certain conditions.

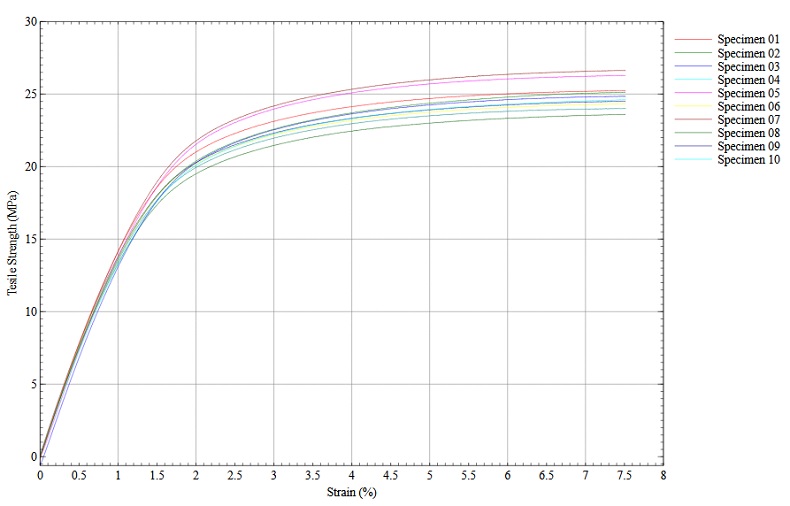

Ten specimens were used in the test, and the test results of the average elastic modulus and tensile stress of the 10 specimens were selected for the finite element analysis.

2.2 Experimental results

The setup arrangements for the tensile test and the images before and after the test are shown in Figure 4. The analyses of the fracture shape of biodegradable materials revealed that damage occurred immediately after the elastic range. This implied that a short plastic range was present before material fracture compared to similar materials.

From the tensile test, the maximum tensile strength of the 10 specimens was estimated as 26.71 MPa; the minimum tensile strength was 23.69 MPa, and the average tensile strength was 24.99 MPa. Damaged specimens after the tensile test are shown in Figure 5, and the tensile strength and modulus of elasticity of the 10 specimens are listed in Table 2.

The test results of PLA material showed that the tensile strength was similar to that of conventional PE and PP. However, the elongation at break of PLA was lower than that of PE and PP applied to conventional buoys. These findings imply that damage can occur if significant deformation arises when the material is used. Strength-deformation and strength-strain rate curves of the tensile test are shown in Figure 6. To further analyze the properties of this new material, we applied its physical properties to flotation and performed a numerical analysis.

3. Impact analysis

3.1 Numerical method

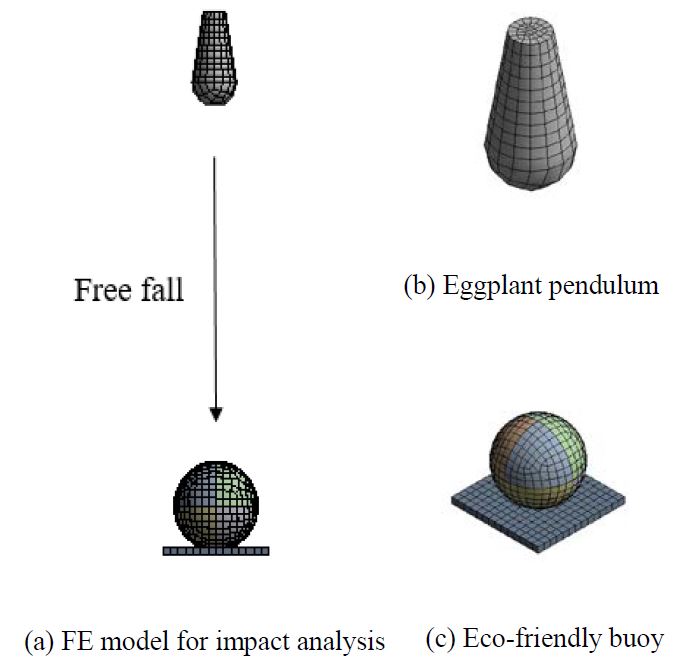

Herein, the impact-resistance test was numerically analyzed using the finite element analysis software ANSYS LS-dyna. Impact-resistance analysis was conducted under the same boundary conditions as those of the eco-friendly buoy certification standard. Therefore, a transient analysis of the free fall of the eggplant pendulum was performed considering the nonlinear material for 1.0 s.

3.2 Modeling and meshing

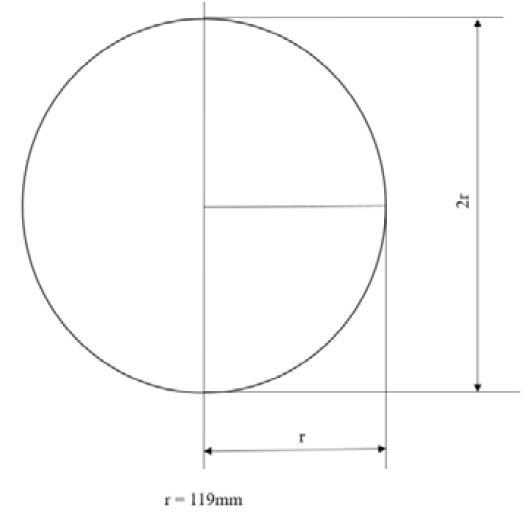

Under the impact-resistance test conditions, a metal plate possessing a thickness of (2 ± 1) cm was fixed without movement. The buoy developed herein was eco-efficient, and it was visually examined for abnormalities, such as cracks, breaks, and tears, on the buoy surface by dropping the eggplant pendulum vertically from a height of 2000 mm at the center of the top surface. The eco-friendly buoy was in the form of a circular sphere with a radius of 119 mm and composed of PLA materials. Figure 7 shows the cross-section of the eco-friendly buoy, except that the thickness of the wired part in the figure has vacant shapes.

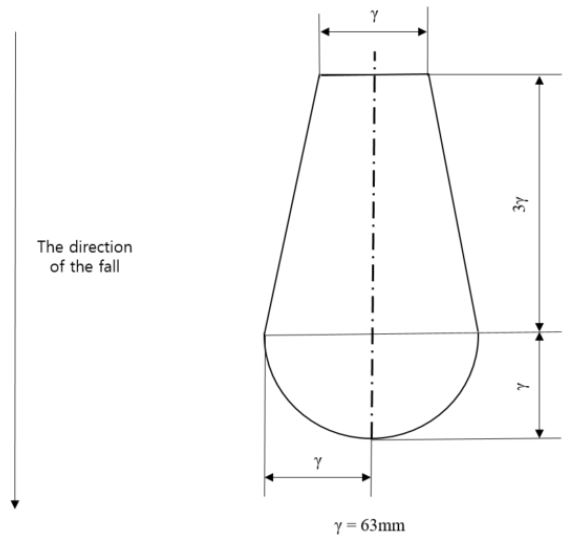

The eggplant pendulum should have a height of 252 mm, an impact radius of 63 mm, a radius of 31.5 mm in the upper part, and a weight of (10 ± 0.1) kg, as shown in Figure 8. The drop direction and impact point were the spherical part of the bottom of the eggplant pendulum, and the impact point of the eco-friendly buoy was determined by selecting the thinnest curved part rather than the bonding part [7][8].

The model used in the analysis is shown in Figure 9. As mentioned previously, the model was composed of an eggplant pendulum and a biodegradable buoy. An eco-friendly buoy was a circular sphere with a diameter of 238 mm, and the eggplant pendulum was modeled with the same size as suggested in the eco-friendly buoy certification. The finite element type applied to the analysis was a 4-node finite strain shell, and the number of nodes and elements used in the finite element model for impact analysis were 10,212 and 10,042, respectively.

3.3 Material properties

The material tensile test results obtained in Figure 6 of the previous experiment were used as the boundary condition of the numerical analysis. As listed in Table 3, the material properties of the buoy and eggplant pendulum correspond to PLA and steel, respectively. The average values obtained from the experiments were used to determine the elastic modulus and tensile strength. Poisson's ratio followed the same conditions as existing plastics.

3.4 Analysis conditions

The fixed boundary conditions were applied by fixing them on a metal plate as suggested in the specification, and the eggplant pendulum with a maximum weight of (10 ± 0.1) kg was modeled and freely dropped to the bouy.

To estimate the optimal thickness to ensure the impact-resistance performance of the newly developed material, analyses were conducted at 1 mm intervals from 1 to 3 mm, considering the injection manufacturing process.

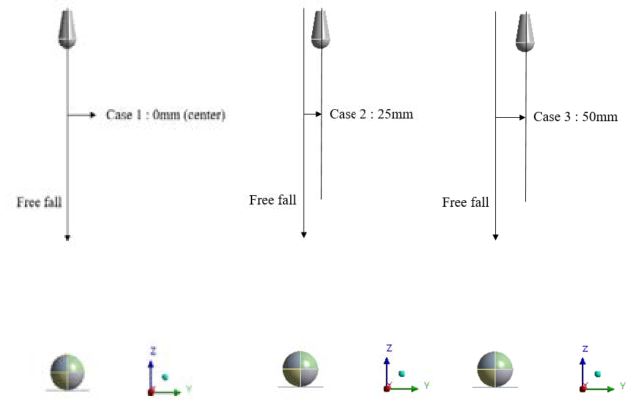

The analysis was conducted for three cases: 0 (center), 25, and 50 mm. The suitability of biodegradable buoys was reviewed considering the diagonal collisions that may occur during the impact test using the eggplant pendulum.

Among the analysis cases, three analysis cases in the diagonal direction and the drop direction are illustrated in Figure 10. The analysis cases considering thickness and direction are summarized in Table 4, and the total number of analysis cases combined is 9.

3.5 Analysis Results

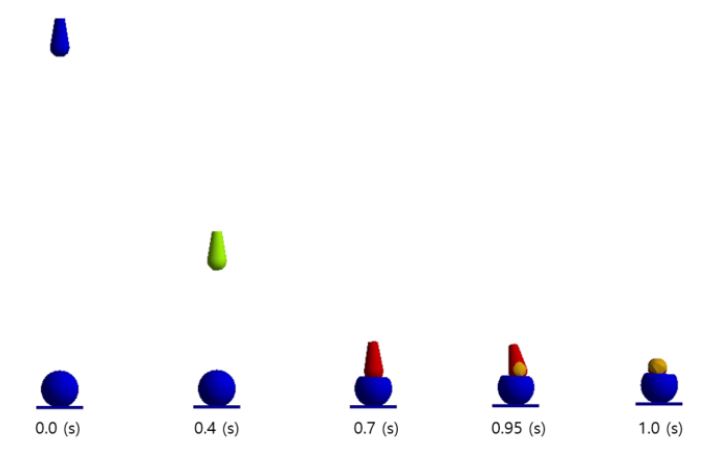

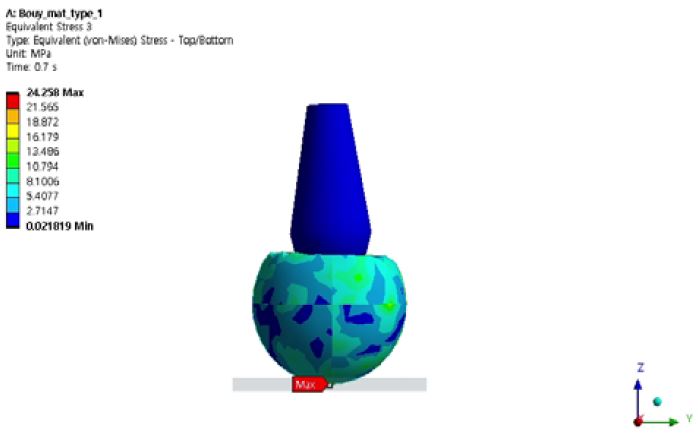

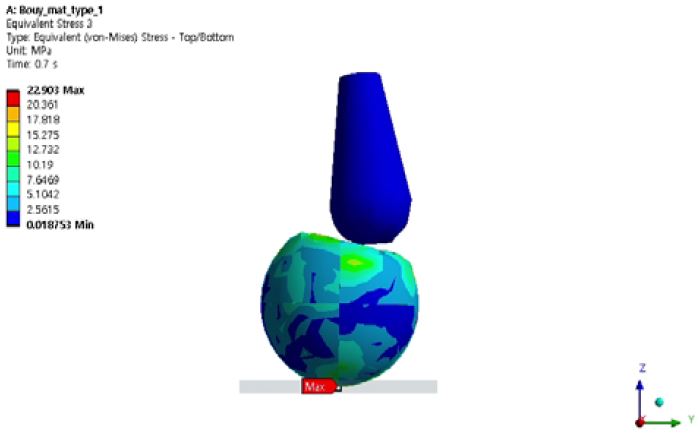

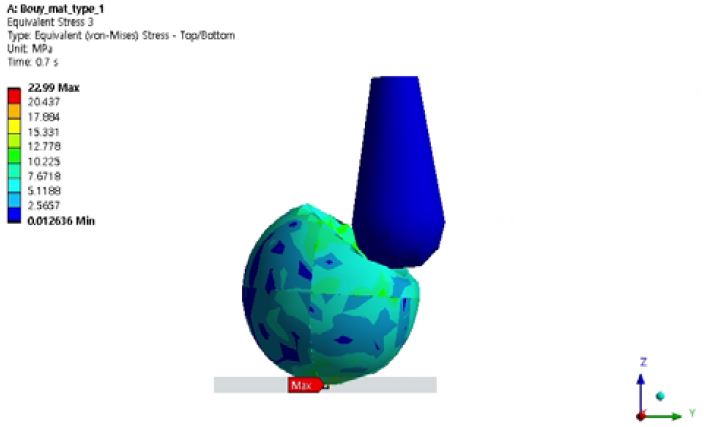

The results of the simulation of collision with the additional buoy of the eggplant pendulum are shown in Figure 11. The eggplant pendulum collided with the buoy at approximately 0.7 s during free fall, and the collision ended at 1.0 s.

A review of the impact shape revealed that owing to the structural characteristics of the eco-friendly buoy with an empty inside, the additional collision part of the eggplant pendulum was crushed and bent inward.

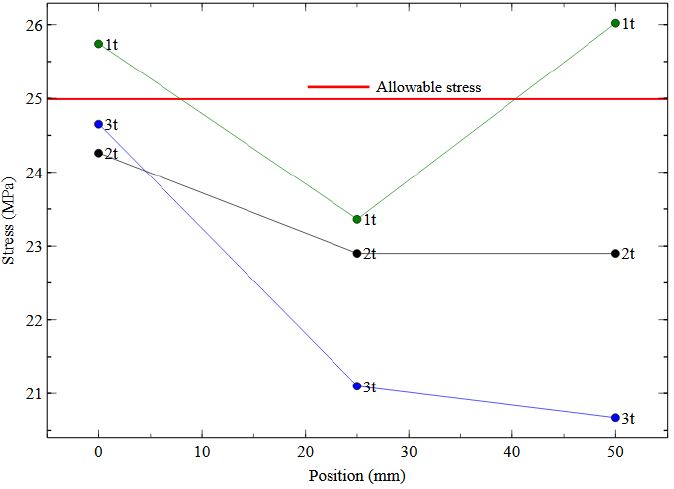

The thicknesses below the red line in the graph of Figure 12, which is the allowable stress value, can satisfy the required impact-resistance performance conditions. The thicknesses below the red line are 2t and 3t.

The detailed results of the impact-resistance analysis are presented in Table 5 and Figure 12. Cases 2-1 and 3-1 had different thicknesses of 2t and 3t. However, 3t was high at a stress of 0.4 MPa. An interpretation error was observed owing to singularity. Because this was a significantly small difference and all values were below the allowable stress, it was defined as satisfying in the selection of the optimal thickness, and the results were reviewed.

Therefore, the impact-resistant performance was considered satisfactory because an allowable stress of 24.99 MPa or less was observed at a thickness of 2t or higher. When only the impact-resistance performance was considered in the eco-friendly buoy certification, 2t was considered the optimal thickness. Because the impact-resistant analysis showed a similar trend for all nine cases, only the figures of three cases based on positions as a representative result (Case 2) were attached.

The analysis results for the 2t-buoy are shown in Figures 13-15. The analysis of the buoy showed that the maximum stress occurs in a part where the metal plate and buoy are fixed across all load cases.

4. Conclusion

As a result of the impact-resistance analysis considering material test-based ASTM D638 of biodegradable materials and the eco-friendly buoy certification standard regulation, the following results were obtained.

- 1) First, through the mechanical properties test of 10 specimens based on the ASTM D638 Standard Test Method for Tension Properties of Plastics, it is showed that the maximum tensile stress was 24.99 MPa. The mechanical material property test reviewed it was confirmed that the tensile strength was similar compared to the characteristics of PE and PP which are materials applied to before buoy, but the elongation of break was lower than that of the existing buoy. This means that damage can easily occur if large deformation occurs when applied the material.

- 2) We take the material tensile test results obtained in the experiment as boundary conditions, and compare the calculation results of the impact under different thickness and different position conditions, and refer to the mechanical properties from the test to the impact-resistant test suggested in the eco-friendly the buoy certification standard concludes that the allowable stress of 24.99 MPa or less is shown at a thickness of 2t or more. If only the impact-resistant performance is considered in eco-friendly buoy certification, 2t is considered the optimal thickness.

- 3) In the further research, actual impact tests on buoys will be conducted, and suitability reviews will be conducted through simulation comparison of results.

Acknowledgments

This research is the result of Rural and fishing village Problem-Solving Support Project ‘Development of eco-friendly buoys for fish-farming using biodegradable plastic materials’ funded by Jeonnam Technopark, Korea.

Author Contributions

Conceptualization, J. S. Jo; Methodology, J. S. Jo; Software,J. S. Jo; Validation, J. S. Jo; Formal Analysis, J. S. Jo and S. J. Choi; Investigation, J. S. Jo; Resources, J. S. Jo; Data Curation, J. S. Jo; Writing—Original Draft Preparation, J. S. Jo; Writing—Review & Editing, J. S. Jo and J. S. Kim.

References

- K. -S. Kim, “A study on Domestic Implementation of G20 Action Plan on Marine Litter,” The Korean Association of Ocean Science and Technology Societies, pp. 87, 2018 (in Korean).

- Y. -J. Lee, H. -M. Park, J. -W. Seong, K. -S. Lee, J. -Y. Mok, H. -S. Kim, and J. -B. Lee, “A survey on the perceptions of Marine debris in Negombo area, Sri Lanka,” The Korean Association of Ocean Science and Technology Societies, pp. 52, 2017 (in Korean).

- H. -J. Koo and M. -K. Shim, “Steel ball drop test of plastic products through structural analysis,” Korean Society for Precision Engineering, pp. 59-60, 2021 (in Korean).

- Y. -H. Kim and J. -Y. Kim, “Impact performance development of plastic component based on CAE,” The Korean Society of Automotive Engineers, pp. 2039-2043, 2011 (in Korean).

- D. -Y. Kim, N. -T. Nguyen, Y. -W. Kim, D. -H. Kim, D. -S. Kim, and H. -Y. Kim, “Study of mechanical characteristics and material modeling for plastics,” The Korean Society of Automotive Engineers, pp. 2006-2009, 2012 (in Korean).

- ASTM, ASTM D638-03, Standard Test Method for tensile Properties of Plastics, 2012.

- The Ministry of Oceans and Fisheries, Standard for certification of eco-friendly buoys, 4.8 Shock resistance, 2022 (in Korean).

- T. -H. Yoon and J. -W. Hong, “Simulation about impact resistance certification test for development of hollow EPP fishery bouy,” The Korean Society of Automotive Engineers, pp. 208-209, 2017 (in Korean).