Analysis of battery lifetime characteristics by variable speeds of electric propulsion motor

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Eco-friendly transportation means, such as electric propulsion ships and electric vehicles, are supplied with energy by batteries, and hence they have less noise, reduced fuel consumption, and are exhaust-free. They convert the direct current voltage of the battery into alternating current by digital converters, which can change the speed of the motor by varying the voltage and frequency. Therefore, harmonics are loaded in the battery input/output and converter's output system, which affects the battery lifetime. The battery has a negative effect on lifetime because of the increase in internal resistance owing to overheating, harmonic content, chemical reactions during charging and discharging, etc. In this study, we measured the total harmonic distortion (THD) of lithium-ion batteries according to the speed change of electric propulsion motors and the internal resistance of the batteries, which is a measure of lifetime prediction. The speed variability of the motor was tested for low-speed, medium-speed, and variable-speed driving conditions. After the test, the effect of the THD on the internal resistance and lifetime of the battery was analyzed. Consequently, it was found that THD was larger when the motor was driven at a variable speed than when it was driven at a constant speed, and it also had a negative effect on battery lifetime.

Keywords:

Electric propulsion ship, Battery lifetime, Total harmonic distortion, Internal resistance of the battery1. Introduction

Recently, a new perception of environmental pollution has emerged. Therefore, to reduce air pollution and carbon emissions, the production of internal combustion engine cars is being reduced worldwide, and strict regulations on carbon emissions from ships are being enforced. To maintain this trend, research on eco-friendly transportation such as battery-powered electric vehicles and electric propulsion ships is being accelerated [1]. The International Maritime Organization (IMO) is tightening regulations with the aim of reducing greenhouse gases and air pollution by 2025. In addition, the Marine Pollution Control Agreement explains regulations on the emission of air pollutants such as nitrogen oxides and sulfur oxides, and the Busan Port Authority (BPA) announced that the use of electric propulsion systems could reduce pollutants such as fine dust and sulfur oxides. As efforts have been made to reduce the emissions of these air pollutants, research on effective energy reduction is actively underway [2].

Electric propulsion is a method that converts and supplies the DC electric energy of the battery to the motor that drives the propulsion load, including electric propulsion ships and electric vehicles. Electric propulsion ships have advantages such as high utilization of the ship’s space, low vibration and noise, high fuel efficiency, and reduced pollutant emissions; however, voltage and frequency changes in the power system can occur when sudden load changes occur. The electric propulsion ship converts the DC power of the storage battery into an alternating current to drive the motor, and the rotation of the motor drives the ship. Inverters are required to convert the DC power from a storage battery into an alternating current. The inverter consists of a digital controller and a power conversion circuit. Because these inverters are controlled by the on/off switching behavior of semiconductors, the output voltage of the inverter becomes square waves, including harmonics not only in the output voltage of the inverter but also in the output voltage of the battery.

In addition, the harmonics generated by the system change depending on the speed and torque of the propulsion motor because electric propulsion ships or electric vehicles vary depending on the load driving environment, such as port voyage, normal voyage, rough voyage, rush hour, or highway driving [2].

The harmonics generated by an electric propulsion ship cause losses such as core loss, steel loss, and eddy current loss in a generator and an electric motor; hysteresis loss in a transformer; and cable loss due to cable resistance in a power cable [3]. To remove harmonic waves from the power line in the electric propulsion system, the size of the capacitor installed in the DC bus is adjusted or the space vector modulation technique of the inverter is used [4].

A battery has dynamic characteristics that affects its lifetime, as the internal parameters change depending on various operating conditions such as temperature, rapid acceleration, vibration, and system harmonics. Thus, the lifetime of the battery and other characteristics were predicted by measuring the changes in these parameters [3][5][6][7].

In particular, if harmonic current flows through the input/output system of the battery, the internal resistance increases, and the lifetime can decrease quickly owing to degradation; therefore, countermeasures are needed [3].

In this study, when the electric propulsion system's motor speed is driven at a constant or variable speed, the harmonic content of the battery output current and the change in internal resistance are measured, and the relationship between these changes and battery lifetime is compared and analyzed [8][9][10].

2. Theory

2.1 SOH (State of health)

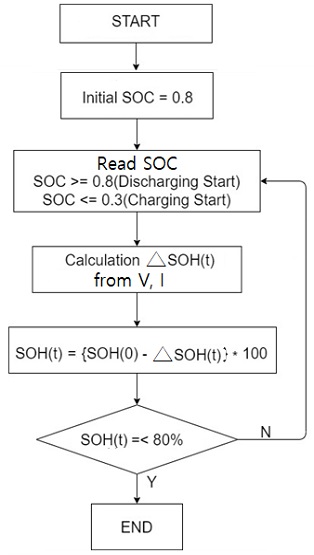

SOH is a percentage representation of the remaining lifetime of a battery and is used to estimate the battery lifetime. Based on the new battery, SOH is defined as 100 %, and when the battery capacity reaches 80 % of its initial capacity after continuous use, the battery has reached the end of its lifetime. In general, it is very difficult to accurately measure the level of aging. Equation (1) shows the method of estimating SOH using the amount of electric power [11][12][13].

| (1) |

where N is the number of charging and discharging cycles to end of lifetime (EOL), Qnew is the capacity of the initial battery, and Pb is the amount of power used.

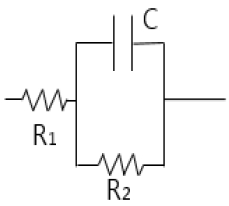

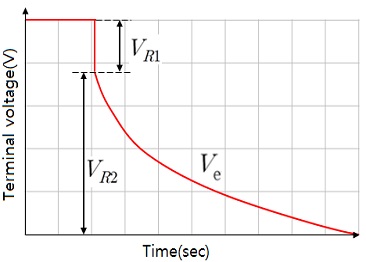

Figure 1 shows Randles' primary battery model. Randles’ model consists of the battery internal resistance R1, ionization loss resistance R2 by charge/discharge currents, and double-layer capacitance C. The dynamic response of the battery terminal voltage to the charge/discharge current is shown in Figure 2, VR1 =R1I, VR2 =R2I, and the response formula is expressed as Vo =R2 I [6][7].

When connecting loads, R1 measures the voltage at the point where the voltage drop occurs for the first time and divides it by the current to obtain a resistance value, which is known to reduce battery lifetime with an increase in the internal resistance [14][15].

2.2 SOC (State of charge)

A lithium secondary battery can be charged and discharged several times, and its capacity refers to its energy storage capacity, which is defined as the total amount of discharged charges when discharged at a constant current from a fully charged state to a fully discharged state. A fully charged state (SOC 100 % state) is defined as a state in which no more current flows by charging at a constant voltage, and a fully discharged state (SOC 0 % state) is defined as a state in which all dischargeable charges are discharged within the range in which the battery is not damaged [13][16].

2.3 THD (Total harmonic distortion)

THD is an indicator of the degree of distortion of waveforms due to harmonics present in a signal and is defined as the ratio of the fundamental frequency to the sum of all harmonic components. The more harmonic components, the greater the THD value, the farther away the shape of the sinusoidal waveform. This means that there are relatively several harmonics compared to basic waves. If the amplitude of the fundamental wave (quantum of the input) in the output signal is V1, the amplitudes of the harmonic waves are V2 and V3, respectively, and THD (%) is calculated using Equation (2).

| (2) |

3. Experiment and consideration

3.1 System configuration

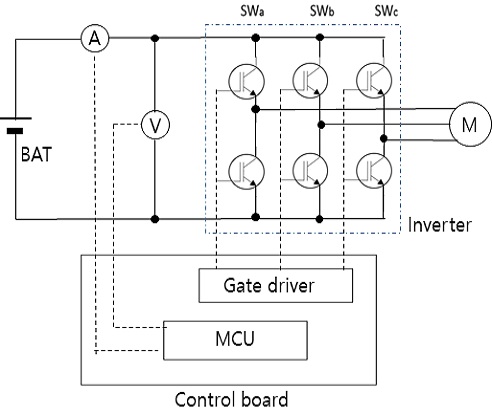

Figure 3 shows the system configuration diagram. By measuring the voltage of the battery, the open-circuit voltage (OCV) can be calculated, and the internal resistance value of the battery can be estimated, which not only allows the battery to predict its life-time but also allows the time for replacement. In addition, the THD is measured using the discharge current of the battery, and the degree of battery aging owing to harmonic waves is predicted compared to the internal resistance value estimated from the voltage. The OCV of a battery is its electromotive force when it is not energized. This OCV depends on the SOC, which is the amount of charge. The voltage increases when the SOC increases, and the voltage decreases when the SOC decreases.

An inverter is a device that produces an alternating current waveform used as an input power source for a ship’s propulsion motor from a direct current power source in the battery. It consists of a microprocessor (MPU), gate driver, and inverter circuit on the control board. In addition, semiconductor switching elements in the inverter must be driven to operate the alternator. These driving signals are produced by the space voltage vector PWM (Pulse width modulation) algorithm of the MPU, which determines the switching frequency and speed of the motor [17].

Consequently, the speed change of the motor changes the harmonic characteristics of the current flowing through the battery and motor, which eventually affects the internal resistance value and lifetime of the battery.

Figure 4 shows the SOH measuring process. After checking the current SOC, charging and discharging are started, and the battery’s voltage and current are measured for each sampling time after charging and discharging. Then, power is calculated from the obtained voltages and currents, which are used to calculate the energy capacity, SOH reduction, and SOH.

3.2 Experiment

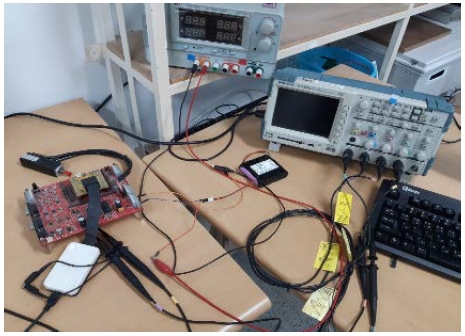

Figure 5 shows a photograph of the equipment used in the driving experiment of an electric propulsion motor (TS4632N2050E510 from TAMAGAWA, 26 W 24 V, AC 3 phase PMSM). The control module used for the frequency control of the inverter (SyncWorks Co. SMC75EVM, DC 6.5∼9.0 V) consists of a microprocessor (TMS320F28335 from TI) and a gate driver. The space voltage vector PWM pulse created by the program is amplified by the gate driver to drive six semiconductor devices in each leg (SWa, SWb, SWc) of the inverter. The control module was programmed with Syncworks JTAG, and the battery pack connected four Samsung ICR18650-26J batteries in series to the SMPS. The battery voltage was measured using a microprocessor by distributing the voltage to the resistor [18].

Figure 6 shows the exterior of the lithium-ion battery used in the experiment, and its specifications are listed in Table 1. Prior to the experiment, the internal resistance was measured, the motor was operated for a certain period of time, and the internal resistance was measured again to compare the amount of change before and after the measurement.

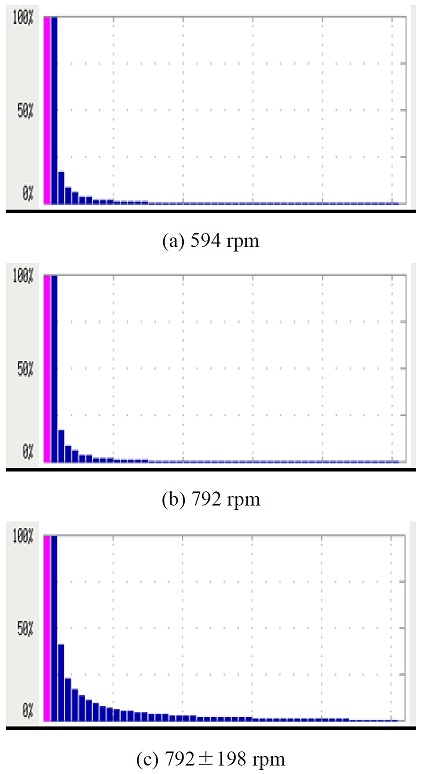

Figure 7 shows a waveform measuring the THD for the battery output current when the motor rotates at low (594 rpm), medium (792 rpm), and variable speeds (792±198 rpm) under no-load conditions. Here, the variable speed is the speed with a deviation of ±198 rpm from the average speed of 792 rpm, which is an alternating output of 594 rpm and 990 rpm at regular intervals. As a result of the measurement, the THD values at low and medium speeds were approximately similar at 32.48%, and the THD values at varying speed rotations were measured in the range of 24% to 50% with a deviation of ±13% based on the average of 37%. The average THD value at variable speed operation is higher than that at low and medium speeds because the mechanical friction force generated when the speed is variable appears as a reverse electromotive force, which affects electrical noise.

Table 2 shows the change in SOH [%] and internal resistance [Ω] to the initial value according to the speed change of the motor. The measuring device included an oscilloscope WS3054 and an electronic load (LP900-A). As a result of measuring the SOH from the voltage and current of the battery, the SOH value decreased the most during variable speed operation. In addition, the amount of change in internal resistance was measured using the OCV technique, as shown in Figure 2. The initial internal resistance value was measured before the operation test, and the internal resistance value was measured again after the operation, and the variation was the largest for the variable speed, compared with the low and medium speeds [18].

This phenomenon is analyzed to promote the degradation or aging of the battery connected to the system by electrical noise of the system.

4. Conclusion

An experiment was conducted on the harmonic characteristics of the output current of a battery and its lifetime characteristics according to the speed change of an electric propulsion motor driven by vector control, resulting in the following conclusions.

- 1. The THD for the battery output current was measured when the motor was rotated at a low (594 rpm), medium (792 rpm), and variable speeds (792±198rpm). The THD values for slow-and medium-speed rotations were approximately similar at 32.48%, and the THD values for variable-speed rotations were measured in the range of 24% to 50% with a deviation of ±13% based on the average of 37%. In addition, the change in SOH was measured according to the speed of the motor. Consequently, it was estimated to be relatively lower at variable speeds than at low and medium speeds. Therefore, it is concluded that variable-speed operation has a negative effect on battery lifetime compared with constant-speed operation.

- 2. To analyze the relationship between the internal resistance of the battery and its lifetime characteristics, the speed of the motor obtained by frequency conversion of the inverter was changed to measure the internal resistance of the battery. Consequently, the increase in R1 was +0.01 [Ω] and +0.06 [Ω] at low and medium speeds, respectively, and approximately +0.09 [Ω] at variable speed operations. Thus, it was shown that the variable speed change of the motor increases the THD of the output current of the battery, decreases the SOH of the battery, and shortens the lifetime of the battery by increasing the internal resistance.

It is estimated that the mechanical inertial force during the forward and reverse rotation of the electric motor affected the electrical noise of the battery discharge current.

Acknowledgments

This research was an improvement of Han Jin-Woo's master's thesis (“Analysis of Lifetime Characteristics of the Storage Battery for the Electric Propulsion Ship Inverter System with Harmonic Waves,” Graduate school of Korea Maritime and Ocean University, Korea, 2021.)

Author Contributions

Conceptualization, J. W. Han and S. G. Lee; Methodology, J. W. Han and S. G. Lee; Software, J. W. Han; Formal Analysis, J. W. Han; Investigation, S. G. Lee; Data Curation, J. W. Han; Writing—Original Draft Preparation, J. W. Han; Writing—Review & Editing, S.G. Lee; Visualization, J. W. Han; Supervision, S. G. Lee; Project Administration, S.G. Lee; Funding Acquisition, S.G. Lee.

References

-

H. K. Ku, H. R. Seo, and J. M. Kim, “Lithium-ion battery energy storage system for power quality improvement in electrical propulsion ships,” The Transactions of the Korean Institute of Power Electronics, vol. 20, no. 4, 2015 (in Korean).

[https://doi.org/10.6113/TKPE.2015.20.4.351]

-

J. S. Kim, H. M. Jeon, and D. K. Kim, “A study on characteristics of each operation mode for hybrid electric propulsion ship by operation circumstances,” Journal of the Korean Society of Marine Engineering, vol. 41, no. 3, pp. 245-250, 2017 (in Korean).

[https://doi.org/10.5916/jkosme.2017.41.3.245]

-

J. S. Kim and S. H. Kim, “Harmonic analysis of power conversion system for torque and speed changing of electric propulsion ship,” Journal of the Korean Society of Marine Environment & Safety, vol. 17. no. 1, pp. 83-88, 2011 (in Korean)

[https://doi.org/10.7837/kosomes.2011.17.1.083]

- A. von Jouanne, A. Wallace, M. MillsPrice, K. Rhinefrank, E. Amon, and T. Lewis, “Harmonic mitigation techniques for hybrid electric vehicle DC-bus traction drives,” 2005 IEEE Vehicle Power and Propulsion Conference, pp. 688-695, 2005.

-

M. T. Talat and A. H. Khawaja, “Li-Ion battery parameter identification using pseudo random noise,” 2019 15th International Conference on Emerging Technologies (ICET), pp. 1-5, 2019.

[https://doi.org/10.1109/ICET48972.2019.8994648]

-

W. R. Cho and B. K. Na, “Electrochemical characteristics of Ru added Li4Ti5O12 as an anode material,” CLEAN TECHNOLOGY, vol. 20, no. 4, pp. 433-438, 2014 (in Korean).

[https://doi.org/10.7464/ksct.2014.20.4.433]

- D. Y. Noh, A Study on the SOH Estimation Method of Lithium Ion Batteries using OCV, M. S. Thesis, Department of Electrical Engineering, Korea University, Korea, 2011 (in Korean).

-

L. Chen, et al., “Improvement of Li-ion battery discharging performance by pulse and sinusoidal current strategies,” IEEE Transactions on Industrial Electronics, vol. 60, no. 12, pp. 5620-5628, 2013.

[https://doi.org/10.1109/TIE.2012.2230599]

-

J. W. Han, et al., “Basic study on the design of a power system for characteristic analysis of battery lifetime,” Journal of Advanced Marine Engineering and Technology, vol. 44, no. 5, pp. 395-400, 2020 (in Korean).

[https://doi.org/10.5916/jamet.2020.44.5.395]

- J. W. Han, T. H. Song, and S. G. Lee, “Measurement of battery internal resistor by variable speeds of electric propulsion motor,” Proceedings of the 45th KOSME Spring Conference, p. 208, 2021 (in Korean).

-

P. O. Hadi and G. Fujita, “Battery charge control by state of health estimation,” Indonesian Journal of Electrical Engineering and Computer Science, vol. 5, no. 3, pp. 508-514, 2017.

[https://doi.org/10.11591/ijeecs.v5.i3.pp508-514]

-

J. H Park, W. C. Cha, U. R. Cho, and J. C. Kim, “State of charge estimation of Li-Ion battery based on CIM and OCV using Extended Kalman Filter, “Journal of the Korean Institute of Illuminating and Electrical Installation Engineers, vol. 28, no. 11, pp. 77-83, 2014 (in Korean).

[https://doi.org/10.5207/JIEIE.2014.28.11.077]

- Y. M. Jung, An Enhanced OCV Reset Algorithm to Improve the Coulomb Counting Method of Li-Polymer Battery for xEVs, M. S. Thesis, Department of Electrical and computer Engineering, Sungkyungwan University, Korea, 2014 (in Korean).

- J. H. Kim, A Study on the screening and Battery Packet Modelling Technique for effective Battery Management System, Ph. D. Dissertation, Department Electrical and Computer Engineering, Seoul National University, Korea, 2012 (in Korean).

- D. Y. Noh, I. S. Hwang, and J. Y. Yoo, “SOH estimation method of lithium polymer batteries using OCV,” Proceedings of the KIPE Conference, pp. 269-270, 2010 (in Korean).

- S. I. Kong, Battery Modelling and SOC Estimation using Extended Kalman Filter, M. S. Thesis, Department of Electrical Engineering, Chungnam national University, Korea, 2013 (in Korean).

- B. Wu, High Power Converters and AC inter-science, Wiley inter-science, pp. 95-150, 2006.

- J. W. Han, Analysis of Lifetime Characteristics of the Storage Battery for the Electric Propulsion Ship Inverter System with Harmonic Waves, M. S. Thesis, Major of Electrical and Electronics, Korea Maritime & Ocean University, Korea, 2021 (in Korean).