Parallel operation control system of low-duty compressor and forcing vaporizer for liquefied natural gas carrier

Copyright ⓒ The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Natural Boil-Off Gas (NBOG) generation during laden voyage of the LNG (Liquefied Natural Gas) Carrier is inevitable because Natural Gas (NG) generally liquefied below –160℃ in the atmospheric state and continuously evaporated by small heat ingress from relatively hot outside. The generated NBOG affects the cargo tank pressure increase, and the Gas Management System (GMS) for LNG Carriers is closely related to the maintenance of the cargo tank pressure and the fuel gas supply system for the main boiler. One of the main problems with LNG Carriers is the handling of NBOG from cargo tanks, and NBOG is generally used as the main boiler fuel for steam production in steam turbine propulsion systems to save cost.

In order to save the CAPEX (CAPital EXpenditures) of the natural fuel gas supply system of the main boiler, a system optimization design was conducted to reduce the number of equipment and reduce the capacity of the equipment. In this paper, newly developed GMS were developed to achieve the unmanned automatic operation control system, Unmanned GMS Control System (UGCS), including the parallel operation control system between the LD (Low Duty) compressor and the forcing vaporizer.

Keywords:

LD compressor, Forcing vaporizer, Parallel operation, Control system, LNGC, BOG, GMS, NG1. Introduction

The configuration of existing main boiler fuel gas supply systems consists of a low-duty (LD) compressor, forcing vaporizer, and gas heater. The speed of the LD compressor is controlled by a variable-frequency drive (VFD) to match the required turn-down ratio to meet the entire range of the fuel gas requirements from the low to high load of the main boiler. With this design, the capacity of the LD compressor had to be designed to supply fuel to the main boiler high load, above the natural boil-off gas (NBOG) of cargo tanks. When more fuel gas than the NBOG is needed, the forcing vaporizer is used to vaporize the liquefied natural gas (LNG) into forced boil-off gas (FBOG) to provide supply additional fuel gas to the main boiler through the LD compressor. In the past, since the above configuration was proposed, large LD compressors capable of handling the high load of the main boiler had to be installed, and an additional VFD had to be installed which increased the capital expenditure (CAPEX) of the fuel gas supply system as well as the maintenance costs.

In order to compensate for these shortcomings and to design an economical system, the VFD for speed control of the LD compressor has been removed, and a system with a reduced LD compressor capacity has been developed. Instead of supplying gas to the inlet side of the LD compressor, a system was developed to supply FBOG directly to the main boiler by connecting it to the outlet side of the LD compressor.

The developed system reduced the amount of equipment and reduced the LD compressor capacity, which thus could enable savings in terms of both CAPEX and maintenance costs. During the initial development stage, the automatic control system depending on the main boiler load variation was not applied. The flow control of the forcing vaporizer was designed and delivered such that the main boiler load variation could not be followed, and the operator could check the main boiler variation to control the constant flow rate set by the operator.

However, the operator had to manually set the flow rate of the forcing vaporizer whenever the main boiler load variation occurred. This is not only inconvenient for the operator, but also contrary to the regulations of certain classification societies that the operator should not operate equipment related to the propulsion system, even if there is a load change in the system, which is a requirement for unmanned operation of the engine room during the voyage.

In order to resolve this issue, the unmanned GMS control system (UGCS) was developed. This includes the automatic flow control of the LD compressor, the automatic load follow-up controller of the forcing vaporizer, the parallel operation controller between the LD compressor and the forcing vaporizer, the parallel operation controller between the LD compressors, and the cargo tank pressure controllers for the ship operation condition. In this paper, we mainly consider the parallel operation control system between the LD compressor and the forcing vaporizer. In order to verify the developed control system, a dynamic simulation was performed, the results were analyzed, and the control system was applied to an LNG carrier.

Although it was developed in dependence on foreign technology, the integrated automation system (IAS) for LNG carrier was able to develop with domestic technology through a localization process, and new processes that incorporate the latest technology in gas processes of LNG carriers are also under continuous development. This served as an opportunity to secure international competitiveness of LNG carriers and continuously develop them.

A distributed control system (DCS), which is mainly applied to the IAS, is provided to configure various methods of control logic. However, process controllers used in LNG carriers mainly use PID controllers, and the controller used in this study also uses a PID controller. Because PID controllers have a simple structure, are easy to apply, have excellent control performance, and allow relatively easy adjustment of the control parameters, they are widely used in the industry and show a penetration rate of more than 90%. PID controllers have many applications in single input and single output systems, despite their excellent performance. However, because it is a linear controller, it has a disadvantage in that it is difficult to obtain satisfactory performance from a PID controller applied to a process exhibiting strong nonlinearity.

2. Fuel Gas Supply System Optimization Design

2.1 Study based on Heat and Mass Balance

LD compressors are used to supply natural gas as fuel for the main boiler.

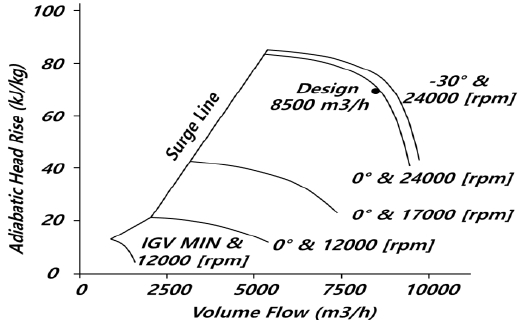

When designed to supply all the fuel gas required by the main boiler through a LD compressor, the capacity is approximately 8,500 m3/h. The inlet pressure of the designed single stage centrifugal compressor is 1.06 bar (a), the inlet temperature is −60°C, and the discharge pressure is 1.96 bar (a). Owing to the large difference between the maximum and minimum amounts of fuel gas required by the main boiler, the operation range of the LD compressor is very wide. In order to meet the turn-down ratio of the main boiler, a VFD must be installed as well as the inlet guide vane adjustment to be configured to control the speed of the LD compressor.

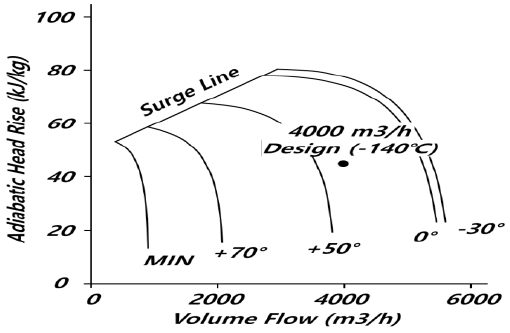

When the LD compressor is selected based on its capability of treating only NBOG, it has a capacity of approximately 4,000 m3/h. In this case, it is designed to supply insufficient fuel gas by using a forcing vaporizer, because it cannot supply all the fuel gas required by the main boiler with the LD compressor. The VFD can be eliminated, because the capacity of the LD compressor has been reduced and the operating range of the machine can be narrowed. The inlet pressure of the designed single-stage centrifugal compressor is 1.06 bar (a), the inlet temperature is −140°C, and the discharge pressure is 1.96 bar (a). In this design, the amount and capacity of equipment are reduced, thereby reducing the CAPEX requirements. However, because the LD compressor and forcing vaporizer must be operated in parallel, it is necessary to establish operation concepts and develop control logic.

The types of vaporizers used in LNG carriers are LNG vaporizers and forcing vaporizers. An LNG vaporizer is mainly used to make gas and supply it to the tank when vapor cannot be returned from the shore while unloading cargo and purging the cargo tank. The forcing vaporizer considered in this study is used to supplement and supply FBOG when the NBOG is less than the fuel demand of the main boiler during laden and ballast voyages.

A GMS manages NBOG generated in the cargo tanks and FBOG produced in the forcing vaporizer. Therefore, the main function of the GMS is to supply fuel gas to the main boiler that produces the steam necessary to achieve the propulsion of the LNG carrier. The equipment components of the GMS include LD compressors, a forcing vaporizer, and a gas heater. In this study, we investigate the GMS optimization design process and consider the new GMS operation method and control system research and development contents that have been optimized.

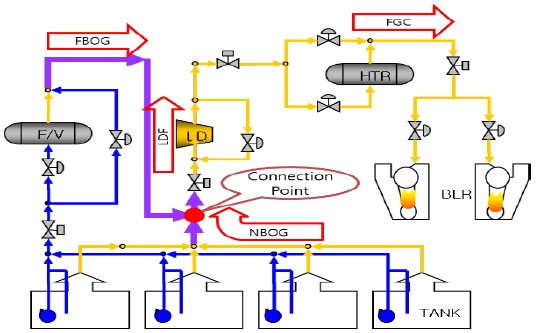

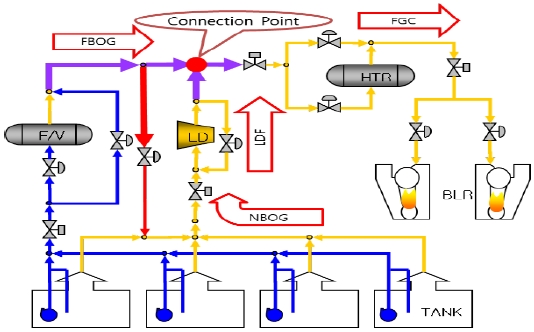

2.1.3.1 Conventional GMS

A conventional GMS supplies all the fuel gas required by the main boiler by compressing and supplying NBOG from the cargo tank to the required pressure using a LD compressor, and the required temperature conditions are properly maintained using a gas heater. In addition, when the fuel gas required by the main boiler is more than the NBOG, it is configured to produce FBOG through the forcing vaporizer and supply it to the main boiler, supplementing the insufficient gas by supplying it to the inlet side of the LD compressor, as shown in Figure 2.

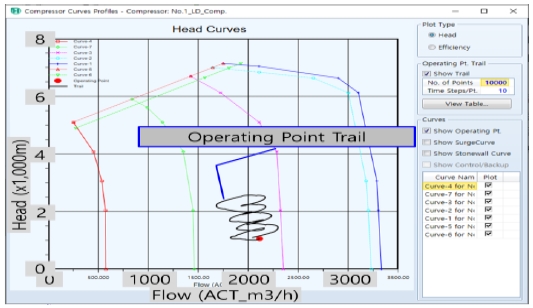

From the perspective of the equipment piping connections, it is easy to configure the control logic as there is no interference between the equipment, with a series connection system from the stripping/spray pump in the cargo tank to the main boiler via the forcing vaporizer, LD compressor, and gas heater. However, from the viewpoint of selecting the capacity of the LD compressor, it must be designed to supply all the gas required by the main boiler through the LD compressor. This requires a large LD compressor, which consumes more energy for operation and additionally requires the speed control of the LD compressor by installing a VFD to match the turn-down ratio required by the boiler. Therefore, the initial investment cost increases. Figure 1 shows the performance curves according to the inlet guide vane control range and the speed control range of the LD compressor.

In order to supply the total amount of fuel gas to the main boiler of the 138,000 m3 LNG carrier, the LD compressor capacity is approximately 8,500 m3/h when it is selected considering the range of the inlet temperature change. Equation (1) shows the relationship between the boiler gas consumption and the fuel gas supply between equipment.

| (1) |

2.1.3.2 New GMS with Manual Operation

The new GMS was developed to complement the conventional GMS. The FBOG produced by the forcing vaporizer is connected to the outlet side of the LD compressor to supply fuel gas to the main boiler. Because of this, the LD compressor can supply only NBOG generated in the cargo tank to the main boiler, and thus it is possible to select a smaller capacity and the VFD for speed control, because the capacity is reduced. This eliminates the need to install the system, which reduces initial investment costs, as well as operating and maintenance costs. Figure 5 shows the equipment arrangement of the new GMS system.

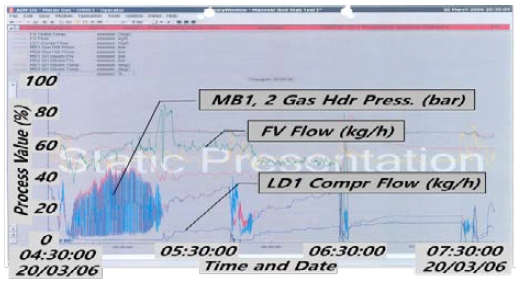

As shown in the system diagram, the forcing vaporizer and the LD compressor are connected in a parallel configuration, and it is very difficult to construct an automatic control system, because two different types of equipment must be operated in parallel. That is, if the LD compressor and the forcing vaporizer are not well matched, the system becomes unstable. In the early stages of development, proper control logic for stable operation of the system had not been developed, and the forcing vaporizer was actuated by manual operation. The LNG carrier could be operated manually because the price of oil was not much higher than the price of gas, and the forced vaporizer was not used frequently. However, as the price difference increased over time, the forcing vaporizer was frequently used, and its manual operation could not be the best solution. Figure 3 shows the system pulsation problem caused by the failure of proper adjustment of the load of the forcing vaporizer due to the reduction in the main boiler load during manual operation of the forcing vaporizer.

Reducing the speed of the turbine engine in order to reduce the ship speed in the absence of an engine room operator during a voyage will initially reduce the load on the LD compressor when the main boiler load is reduced. However, this decrease in the load stops occurring when the load on the LD compressor is lowered to the minimum. At this point, the forcing vaporizer encounters a situation in which FBOG is produced and supplied to the main boiler while maintaining a manually set value in a high load region. In this condition, if the operator does not intervene, the gas produced in the gas supply pipe accumulates because the main boiler uses less gas and the forcing vaporizer continues to produce gas. The pressure increases due to the accumulated gas, which causes a surge phenomenon in the LD compressor, thereby operating the surge prevention controller. The pressure in the pipe fluctuates, and the main boiler gas supply controller also fluctuates. As the pressure fluctuates, the flow controller of the forcing vaporizer also suffers from a severe pulsation, which leads to an emergency situation in which it is no longer possible to operate. To prevent this, if variations in the main boiler load are required, the operator must adjust the gas output of the forcing vaporizer accordingly.

The capacity selection of the LD compressor is shown in Figure 4 only NBOG generated in the cargo tank requires a capacity selection of approximately 4,000 m3/h, considering the range of the inlet temperature change. The additional fuel gas is supplied to the main boiler by the FBOG produced using the forcing vaporizer. Equation (2) shows the relationship between the boiler gas consumption and the fuel gas supply between equipment.

| (2) |

2.1.3.3 New GMS with Automatic Operation

The new GMS system developed for manual operation may violate certain classification regulations. The classification regulations state that the systems related to the main propulsion system must not be operated by the operator during unmanned engine room operation. Therefore, it is essential to develop a new GMS system to enable automatic operation. In addition, as shown in Figure 5, a high pressure prevention line and a control valve were installed to enable automatic operation of the new GMS system. The installed control valve prevents high pressure by recirculating excess gas during automatic operation when the main boiler load is operated at a load of approximately 24% or less, which is the minimum flow rate of a LD compressor, and when operating at a load of approximately 20% or less, which is the minimum flow rate of a forcing vaporizer. It can be operated safely by recirculating gas into the cargo tank to prevent abnormally high pressure in the fuel gas supply pipe when sudden load fluctuations of more than 5% per second or abnormal operation occur during the operation of the LD compressor and forcing vaporizer. In this way, the system is controlled by a high-pressure prevention controller.

3. New GMS Control System Developed

3.1 LD Compressor Control System

The LD compressor control system is equipped with a position controller for the main boiler fuel gas control valve and a flow controller as standard.

The valve position controller of the LD compressor controls the inlet guide vane of the LD compressor for maintaining a constant position of the fuel gas control valve of the main boiler. The fuel gas control valve of the main boiler is controlled by a fuel gas controller to keep the boiler steam pressure constant.

The flow controller of the LD compressor is used to supply the gas to the main boiler at a constant flow rate as well as to regulate the fuel gas supplied to the main boiler to maintain a constant pressure in the cargo tank.

In order to prevent the low pressure of the cargo tank, a cargo tank low-pressure controller is provided, which operates so as to reduce the flow rate of the LD compressor with the highest priority to prevent the cargo tank from reaching low pressure.

3.2 Forcing Vaporizer Control System

The forcing vaporizer control system includes a flow rate control for controlling the amount of FBOG and a temperature control for controlling the outlet temperature.

The developed controller includes variable parameters based on the flow rate to expand the operating range of the equipment.

3.3 Gas Heater Control System

The gas heater employs a heat exchanger using steam, and does not control the amount of steam supplied, but controls the temperature by controlling the amount of gas supplied to the heat exchanger and the amount of bypass to control the gas discharge temperature. Accordingly, the amount of steam supplied is configured to automatically supply as much steam as the amount of steam condensation.

3.4 LD Compressor and Forcing Vaporizer Parallel Operation Control System

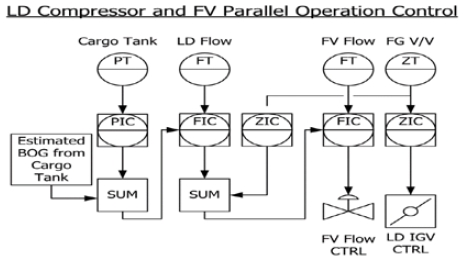

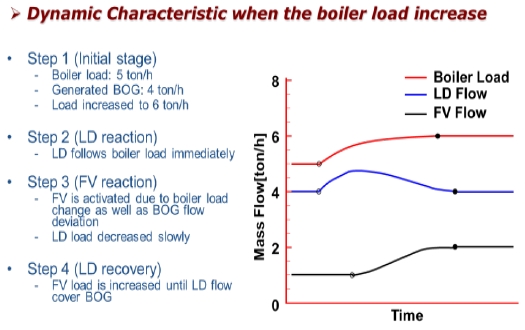

These controllers were developed to enable stable parallel operation when supplying the fuel gas required by the main boiler by simultaneously operating the LD compressor and the forcing vaporizer. When the main boiler load changes, the position controller of the LD compressor is preemptively operated, and the FBOG production amount of the forcing vaporizer is gradually adjusted by the trailing, such that the LD compressor can supply the amount of NBOG available in the cargo tank. When the load change of the main boiler is large, the forcing vaporizer is configured to follow the load at the same time as the load of the LD compressor. Figure 6 schematically shows the LD compressor and forcing vaporizer parallel operation controllers.

Figure 7 shows the expected flow dynamic characteristics of equipment according to the increase in boiler load in the LD compressor and forcing vaporizer parallel operation control system.

4. Dynamic Simulation and Study

4.1 Dynamic Simulation

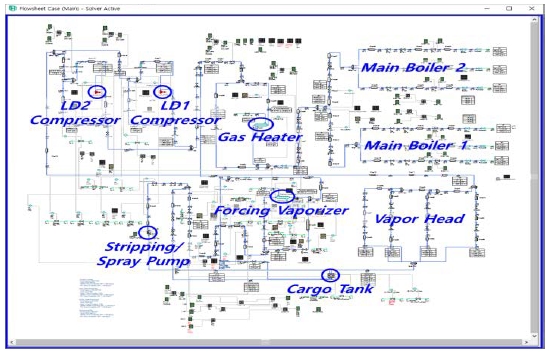

Because the actual ship test was limited, simulation tests were used for verification. Various dynamic simulation software packages have been developed, but the package used for this simulation was a commercial process simulator, Aspen HYSYS V10 simulation package [2][3].

Modeling was performed using the Peng–Robinson state equation, which known to be relatively suitable for cryogenic gas processes [4].

A model was built for the detailed characteristics of the new GMS-related equipment.

The technical background and modeling methods for major component modeling is based on the thermal/fluid and mathematical models provided by HYSYS. Data such as performance curves for LD compressors, heat transfer coefficients for forcing vaporizer, specifications of various equipment, and flow coefficients for control valves are based on actual data provided by suppliers. Figure 8 shows the entire dynamic model of the new GMS.

4.2 New GMS Simulation Results

In order to run the new GMS dynamic simulation model, the simulation was performed by finding the optimal parameters for the modeled controllers. The initial parameters of some controllers were set using the automatic tuning function provided by HYSYS, and some controller parameters were found based on the tuning method of Ziegler and Nichols. For others, the optimal parameters were obtained through manual tuning based on experience. The simulation was performed by searching for the optimal parameters [5][6][7].

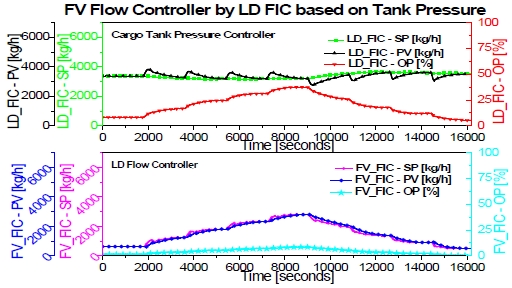

If the speed of the steam turbine propulsion system is increased to increase the ship's speed on the bridge, the steam consumption of the steam turbine increases and the steam pressure of the main boiler decreases. The main boiler operates the system to maintain pressure by burning more fuel gas to maintain the pressure. When the fuel gas consumption increases, in order to increase the fuel gas supply, the fuel gas supply system first reacts with an LD compressor to increase and supply the required gas. The gas supply flow controller of the forcing vaporizer checks the fuel supply flow of the LD compressor, and automatically calculates the available NBOG in the cargo tank to perform control. Accordingly, the gas production amount FBOG of the forcing vaporizer is controlled such that the fuel gas supply amount of the LD compressor can be supplied only with the available NBOG in the cargo tank. The remote setting value of the forcing vaporizer flow controller is sent from a separate LD compressor flow controller. Therefore, in the transitional state, the LD compressor operates preemptively to the load variation, and the forcing vaporizer operates to supplement it. This parallel operation control system is designed to automatically and stably supply the fuel gas required by the boiler [8].

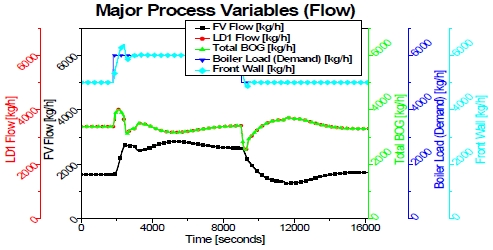

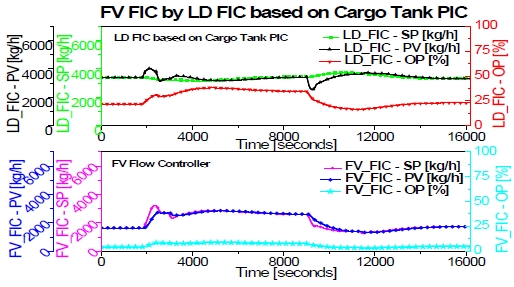

4.2.1.1 Increase and Decrease Boiler Load (Four-Step Change 4,000 kg/h

6,000 kg/h)

6,000 kg/h)

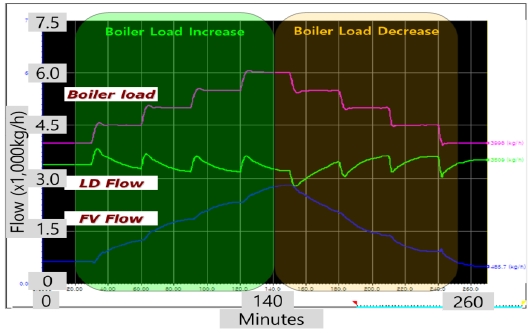

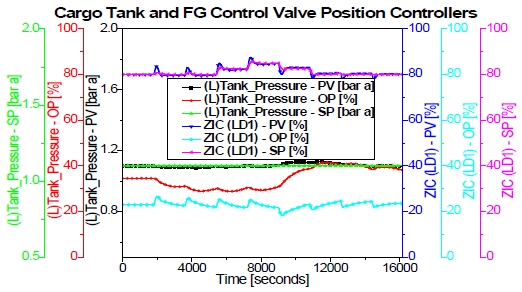

Dynamic simulations were performed to confirm that the new GMS control systems were properly controlled as the boiler load increased and decreased in four steps. The results are shown in Figure 9 to Figure 12. In order to confirm the controllability and responsiveness of the new GMS control system, a step response test was conducted, and the load of the LD compressor and forcing vaporizer was increased and decreased by increasing and decreasing the load of the main boiler in four steps from 4,000 to 6,000 kg/h vice versa. The GMS system was well controlled by the new GMS control system.

LD Compressor Performance Curve with Operating Point for Four-Step Boiler Load Variation (4,000 kg/h to/from 6,000 kg/h)

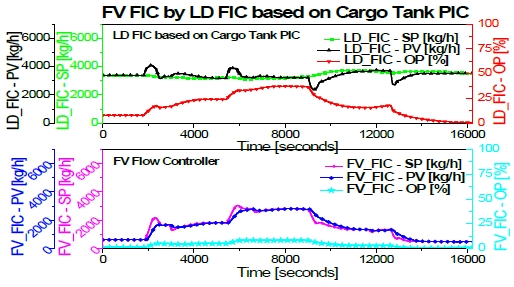

Flow Trend of Parallel Operation between LD Compressor and FV for Four-Step Boiler Load Variation (4,000 kg/h to/from 6,000 kg/h)

Controllers Trend of Parallel Operation between LD Compressor and FV for Four-Step Boiler Load Variation (4,000 kg/h to/from 6,000 kg/h)

Controllers Trend of Parallel Operation between LD Compressor and FV for Four-Step Boiler Load Variation (4,000 kg/h to/from 6,000 kg/h)

4.2.1.2 Increase and Decrease Boiler Load (1 Step Change 5,000 kg/h

6,000 kg/h)

6,000 kg/h)

Dynamic simulations were performed to confirm that the new GMS control systems were properly controlled as the boiler load increased and decreased in one step. The results are shown in Figure 13 and Figure 14. A step response test was conducted, whereby the load of the LD compressor and forcing vaporizer was increased and decreased by increasing and decreasing the load of the main boiler in one step from 5,000 to 6,000 kg/h and vice versa. The GMS system was well controlled by the new GMS control system.

Flow Trend of Parallel Operation between LD Compressor and FV for One-Step Boiler Load Variation (5,000 kg/h to/from 6,000 kg/h)

Controllers Trend of Parallel Operation between LD Compressor and FV for One-Step Boiler Load Variation (5,000 kg/h to/from 6,000 kg/h)

4.2.1.3 Increase and Decrease Boiler Load (Two-Step Change 4,000 kg/h

6,000 kg/h)

6,000 kg/h)

Dynamic simulations were performed to confirm that the new GMS control systems were properly controlled as the boiler load increased and decreased in two steps. The results are shown in Figure 15 and Figure 16. A step response test was conducted, whereby the load of the LD compressor and forcing vaporizer was increased and decreased by increasing and decreasing the load of the main boiler in two steps from 4,000 to 6,000 kg/h and vice versa.

Flow Trend of Parallel Operation between LD Compressor and FV for Two-Step Boiler Load Variation (4,000 kg/h to/from 6,000 kg/h)

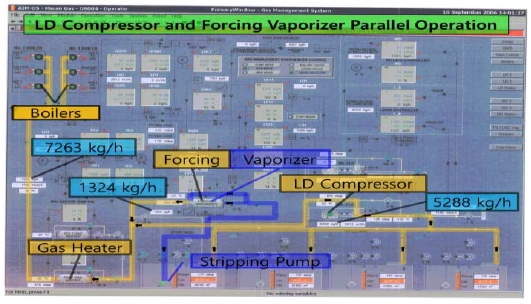

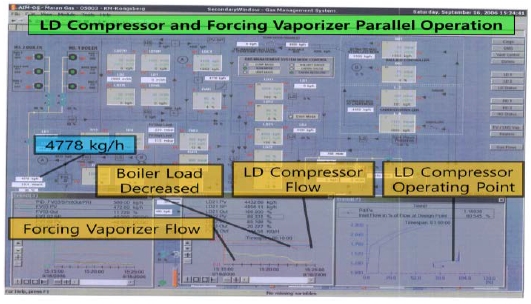

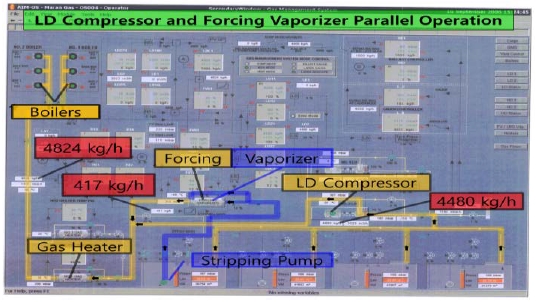

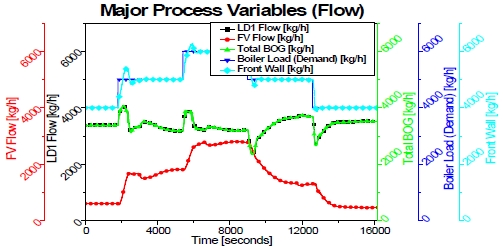

4.3 LNG Carrier Application Test

The developed UGCS was applied to the LNG carrier and delivered. The parallel operation of a LD compressor and a forcing vaporizer is shown in Figure 17–Figure 19. The main boiler load varied from 4,824 to 7,263 kg/h, the load of the LD compressor varied from 4,480 to 5,288 kg/h, and the forcing vaporizer changed from 417 to 1,324 kg/h. It was confirmed that LD compressors and forcing vaporizer tracked the boiler load variations well.

5. Conclusion

This paper presents the results of research and development of an UGCS suitable for the new GMS of LNG carriers.

The cargo tank pressure of LNG carriers increases owing to NBOG generated in the cargo tank. Steam is produced by supplying NBOG generated as a fuel to the main boiler to prevent the cargo tank pressure from rising and to maintain constant pressure. Using the generated steam, the steam turbine propulsion system is driven to make the LNG carrier sail under propulsion power. During this process, the details of research and development on the UGCS of the new GMS, which were conceived during the design optimization of the fuel gas supply system of the main boiler, were examined in detail. In particular, the parallel operation control system between the LD compressor and forcing vaporizer was focused upon.

The features of the developed control system are as follows:

- 1) It was confirmed that the functions of the newly designed GMS control system satisfied the required accuracy of ±2.0% in the steady state and the accuracy of ±5.0% in the transient state.

- 2) A parallel operation controller was developed and applied to enable safe parallel operation of an LD compressor and forcing vaporizer with significantly different dynamic characteristics.

- 3) A flow controller of the forcing vaporizer was developed and applied to make the flow rate of the fuel gas supply of the LD compressor equal to the amount of the available NBOG in the cargo tank.

- 4) A position controller of the main boiler fuel gas control valve was applied to the LD compressors such that the fuel gas supply could be smoothly performed according to the load variation of the main boiler.

- 5) In order to expand the operation range of the forcing vaporizer, a flow-based variable parameter flow controller and temperature controller were developed and applied.

The algorithm of the developed control systems was tested for its validity through dynamic simulations; it has been successfully applied to the IAS of LNG carriers and confirmed to be operating well.

In this study, the parallel operation control system of the LD compressor and the forcing vaporizer, which occupies the core of the UGCS, was examined. The consideration of a parallel operation control system between LD compressors and a cargo tank pressure control system capable of responding to ship operation conditions are left as future tasks.

Acknowledgments

This study was an extension of the Doctoral thesis by Sung-Kak Lyu (A Study on the Parallel Operation Control System of LD Compressor and Forcing Vaporizer for Liquefied Natural Gas (LNG) Carrier, Korea Maritime and Ocean University Graduate School).

Author Contributions

Conceptualization, S. K. Lyu and Y. S. Kim; methodology, S. K. Lyu; Software, S. K. Lyu; Formal Analysis, S. K. Lyu; Investigation, S. K. Lyu and J. Y. Kim; Resources, S. K. Lyu; Data curation S. K. Lyu; Writing-Original Draft Preparation, S. K. Lyu; Writing-Review & Editing, S. K. Lyu; Visualization, S. K. Lyu; Supervision, S. G. Lee and Y. S. Kim; Project Administration, S. K. Lyu; Funding Acquisition, All Authors.

References

- J. H. Choi, H. S. Yoo, K. N. Yoo, A. Heo, D. Y. Lee, and S. K. Lyu, “Third wave of gas management system in LNG carrier - VaCo system,” Special Issue of the Society of Naval Architect of Korea, pp. 89-93, 2007 (in Korean).

- H. J. Shin, Model Predictive Control of Mixed Refrigerant Liquefaction Process for Stable and Economic Operation in FLNG, Master Thesis, Department of Chemical and Biological Engineering, Seoul National University, KOREA, 2015 (in Korean).

-

J. I. Yoon, et al, “Characteristics of cryogenic cascade refrigeration cycle for liquefaction of natural gas with the pressure drop of heat exchanger,” Journal of the Korean Society of Marine Engineering, vol. 36, no. 6, pp. 756-761, 2012 (in Korean).

[https://doi.org/10.5916/jkosme.2012.36.6.756]

-

M. S. Khan, S. G. Lee, G. P. Rangaiah, and M. Y. Lee, “Knowledge based decision making method for the selection of mixed refrigerant systems for energy efficient LNG processes,” Applied Energy, vol. 111, pp. 1018-1031, 2013.

[https://doi.org/10.1016/j.apenergy.2013.06.010]

- B. A. Ogunnaike and W. H. Ray, Process Dynamic, Modeling, and Control, Oxford University Press, 1994.

- J. G. Ziegler and N. B. Nichols, “Optimum settings for automatic controllers,” Transactions ASME, vol. 64, no. 11, pp. 759-768(759-768). 1942.

- F. Haugen, Basic Dynamics and Control, TechTeach, 2010.

- M. Hansen, Model Based Control of Single-Phase Marine Cooling Systems, Ph.D. Dissertation, Department of Electronic Systems, Aalborg University, Denmark, 2013.