Development of a visualized underwater rescue-rope system

Copyright ⓒ The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Underwater rescue-ropes have been used for the underwater activities of divers such as lifesaving, exploration, investigation, and filming and for securing their return paths. Studies have been conducted to visualize rescue-rope by applying an optical fiber and light emitting diode (LED) to pre-existing non-luminous ropes made of nylon, polyethylene, or polypropylene. Furthermore, previous results showed that the visualized ropes could be used for underwater experiments. However, further studies on the reduction of the heat radiated by the low driving current of the LED and an efficient utilization of luminous flux are necessary, as the optical fiber used in the previous study would be damaged by the radiation of the light source. Hence, this study was conducted to utilize the electrical and optical features of the LED and the optical fiber, and to develop a high luminance underwater rescue-rope that is stable for long-term operation. By applying an optimal light concentrator between the LED light source and the optical fiber, the surface luminance was increased by 180% at half the driving current of the LED light source compared with that in the previous study.

Keywords:

Rescue-rope, Optical fiber, Light emitting diode, Luminance, Underwater1. Introduction

Rescue-ropes have been widely used for underwater activities of divers such as lifesaving, exploration, investigation, and filming as well as for securing their return paths, as shown in Figure 1 [1]-[3].

Visualized underwater rescue-ropes have been in demand for other proactive activities and safety. Therefore, studies have been conducted to visualize rescue-rope by applying a high luminance light emitting diode (LED) to a side-emitting optical fiber as a replacement of existing non-luminous ropes made of nylon, polyethylene, or polypropylene.

The fundamental issues of existing rescue-rope have been solved, as the radiation of the prototype rescue-rope, which is visible underwater, is green in color with a wavelength of 525 nm and a high transmittance. Further, the surface luminance of the prototype is 120 cd/m2.

In a previous study, the maximum surface luminance of the end of the optical fiber was 1,500 cd/m2, but the heat from the LED frequently damaged the optical fiber [4][5].

Accordingly, a high luminance rescue-rope usable in any underwater environment where floating materials and microbes cause high turbidity is required for application to diving activities.

This study was conducted to apply a light concentrator that focuses the luminous flux from an LED onto the core of a side-emitting optical fiber, to control the shielding and reflection of the jacket, and to apply a reflector to the end of the optical fiber so that the surface luminance is increased with stability, while the driving current of the LED remains the same as that in the previous study [4][5].

As a rescue-rope using a side-emitting optical fiber does not require electric wiring, the issues of waterproofness and electrical insulation are resolved fundamentally. Furthermore, a visualized underwater rescue-rope is expected to be utilized with economic and technical distinctions in several fields such as shipboard decoration lights, safety lines for railroad platforms, tunnel guide lines, and landscape uses [6].

2. Method of Luminance Improvement

2.1 Structure of the optical fibers

The optical fiber used to visualize the underwater rescue-rope is made of polymethyl methacrylate (PMMA), which has no problems related to electric insulation and corrosion in an underwater environment [7]. The light attenuation rate at the core is 0.15 dB/m [8][9].

The quantitative performance indicator of the rescue-rope is the brightness that can be recognized by divers from a certain distance; therefore, the surface luminance of the optical fiber is used as the criterion.

The specifications of the light source used in the experiment are shown in Table 1, which is a 525 nm device-on-board (DOB) type green LED package [10].

The main factors influencing the selection of the light source for the underwater rescue-rope were the total luminous flux and the surface luminance (lm/mm2) within the core area of the optical fiber.

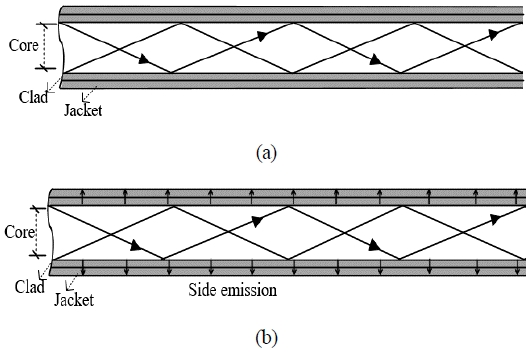

The structure of an optical fiber for communication and side emission purposes consists of a core, clad, and jacket, as shown in Figure 2.

The light passes through the core. For communication, the clad shields the light that propagates into the core, whereas for side emission, the clad is applied to radiate a certain amount of light outward, at right angles to the propagation passage of the light.

In addition, for communication, the jacket is used only to protect the clad, whereas for side emission, the jacket is made of materials with a high transparent rate so that it can also radiate the light to the clad outward.

The specifications of the optical fiber used as an underwater rescue-rope are shown in Table 2. The following experimental studies were conducted to enhance the surface luminance of the side-emitting optical fiber:

- Application of a light concentrator between the light source and the optical fiber

- Shielding and reflection control of the jacket

- Application of a reflector at the end of the optical fiber

2.2 Application of a light concentrator

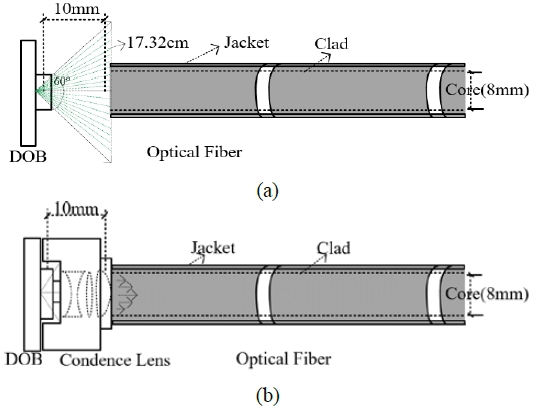

The beam angle of the LED package is generally greater than 110° unless a specially designed lens is applied. In addition, the radiant heat from the luminous surface of a high-power LED is over 100 °C, which indicates that the optical fiber may be damaged if its core and the luminous area of the LED come into direct contact [11].

As shown in Figure 3 (a), the distance between the LED package and the optical fiber should be at least 10 mm to prevent the damage to the optical fiber by the radiant heat. In this case, 60% of the luminous flux from the LED is condensed at the core and the rest dissipates. Therefore, a light concentrator between the LED package and the optical fiber is required to utilize the luminous flux fully. In this study, a multi-layer glass lens composed of a concave lens and 3-convex lens was applied as the light concentrator. Subsequently, an optimal light concentrator that focuses the radiated flux from the LED onto the core of the optical fiber was placed [12]-[14].

The beam angle of the light concentrator was narrower than 60° and its height was 10 mm. As shown in Figure 3 (b), the light concentrator was inserted between the LED package and the optical fiber. To analyze the efficiency of the light concentrator, the ratio of the luminous area of Figure 3 (a) without the concentrator; and Figure 3 (b) with one, at a 10mm from the LED was compared. As a result, the following is obtained:

In Figure 3 (a), the radius passing through the luminous flux at a beam angle of 120° is 17.32 mm (=10×tan60°) and the cross-section area of the solid angle is approximately 940 mm2 (=Π×17.322). Only the luminous flux incident on the cross-section area of 200 mm2 that corresponds to the radius of 8 mm was focused on the core.

In Figure 3 (b), the radius passing through the luminous flux at a beam angle of 60° is 5.77 mm (=10×tan30°). Therefore, the luminous flux that corresponds to a beam angle of 120° was focused on the core. Similarly, by the application of a light concentrator with a beam angle of 60°, the luminous flux focused on the core was increased by 470% (=940÷200).

Even considering an absorption and reflection loss of 30% in the light concentrator, the incident luminous flux onto the core was increased by 330%. The surface luminance measured at the end of the optical fiber was increased by 170%, as the forward current of the LED was fixed at 5 A and a light concentrator was applied at a 20-m-long optical fiber.

2.3 Control of shielding and reflection in optical fiber

The light radiated from the surface of the optical fiber is diffused underwater and a rescue-rope with a higher surface luminance is better recognized by divers in turbid water.

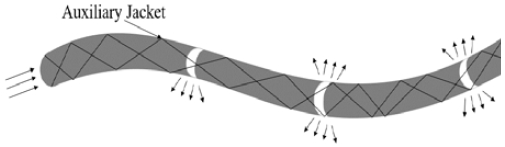

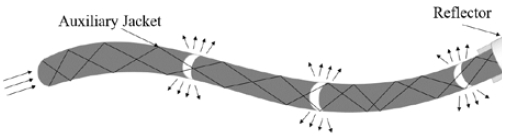

In this study, a 100-cm-long auxiliary jacket with a reflectance of 50% and a transmissivity of 20% was covered on the optical fiber at intervals of 10 cm, as shown in Figure 4. It was used to prevent the surface luminance of the optical fiber from decreasing, as more luminous flux was radiated outward with the increase in the distance of the optical fiber from the light source.

In addition, a reflector with a reflectance of 85% was covered at the end of the optical fiber to reduce the loss of luminous flux as shown in Figure 5.

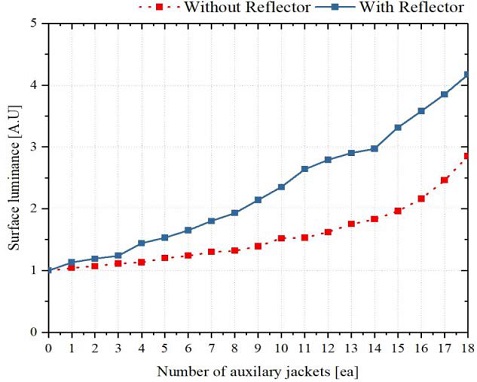

Figure 6 shows the surface luminance of the optical fiber after applying all the three aforementioned techniques. The surface luminance increased considerably, as the number of jackets was increased and the reflector was installed. The surface luminance was increased by 280% with the installation of auxiliary jackets. In addition, the surface luminance was increased by a maximum of 430% after applying the reflector.

3. Design and Fabrication

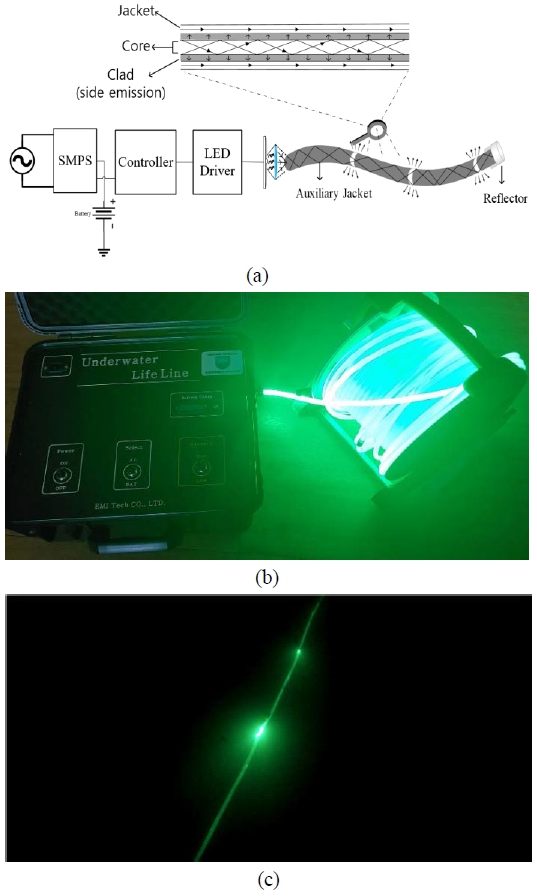

The configuration of the prototype rescue-rope system, which was developed using all the aforementioned techniques to increase the surface luminance of the optical fiber, is shown in Figure 7. Considering the portability and operation time, a commercial-frequency AC and a DC battery can be alternately used as the power sources. The remaining energy level is always indicated, which is necessary as the activities and return path of the divers may be put in danger if the power source of the rescue-rope shuts down during operations.

Prototype visualization rescue-rope system (a) Configuration; (b) Photographs; (c) Luminous in water

The forward current and voltage of the LED of the prototype rescue-rope system were 5 A and 4.7 V, respectively. By applying the light concentrator, jackets, and reflector, the optical fiber showed high performance in environments with high turbidity. Using the prototype rescue-rope system in Figure 7 (b), the surface luminance measured at the end of the optical fiber was compared with the result of the previous study.

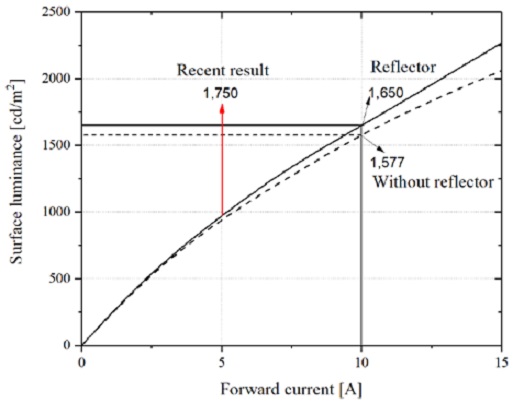

In the previous study, the driving current of the LED was increased to enhance the luminance. Consequently, the surface luminance was a maximum of 1,650 cd/m2 at a driving current of 10 A, and 950 cd/m2 at 5 A as shown in Figure 8.

Upon applying a light concentrator between the LED package and the optical fiber, controlling the shielding and reflection of the optical fiber jacket, and applying the reflector, the surface luminance of the optical fiber was measured to be 1,750 cd/m2 at a driving current of 5 A, indicating an increase of 180%.

4. Conclusions

In this paper, methods for increasing the luminance of underwater rescue-ropes were proposed and a prototype was designed. The three methods were the placement of an optimal light concentrator between the LED light source and the optical fiber, the control of the shielding and reflection of the optical fiber jacket, and the application of a reflector at the end of the optical fiber.

The light concentrator increased the luminous flux focused on the core by 330% and the auxiliary jackets increased the surface luminance by 280%. In addition, the reflector increased the surface luminance by a maximum of 430%.

The performance evaluation of the prototype showed that the surface luminance was the same as that in the previous study at only half the driving current i.e., 5 A, whereas its maximum luminance was increased by 180%.

Acknowledgments

This study was sponsored by the LINC of the NRF. This paper is an improved version of the published paper; “Design and Fabrication of an Underwater Visualization Rescue-rope,” Journal of the Korean Society of Marine Engineering, vol. 42, no. 9, pp. 767-771, November 2018.

Author Contributions

Conceptualization and methodology, G. S. Kil and N. H. Kim; Design and Fabrication, G. S. Kil, N. H. Kim, and T. H. Kang; Field experiment and analysis, T. H. Kang and D. H. An; Writing-Original Draft Preparation, G. S. Kil, N. H. Kim, and T. S. Kim; Supervision and Project Administration, G. S. Kil

References

- Enforcement Decree of the Act on the Safety, Promotion, Etc. of Underwater Leisure Activities, Article 5, Ministry of Oceans and Fisheries, July 26, 2017. Available: http://elaw.klri.re.kr/eng_mobile/viewer.do?hseq=45055&type=part&key=42

-

P. Jackovics, “Analysis with applied statistics of the safety use of rope rescue equipment,” International Journal of Occupational Safety and Ergonomics, vol. 25, pp 1-10, 2019

[https://doi.org/10.1080/10803548.2019.1569358]

- A Study on the Safety Management Standard on Underwater activities, Ministry of Public Safety and Security, p.92, Dec. 2015

-

W. H. Kim, G. M. Wang, G. S. Kil, D. J. Kim, B. W. Seo, S. Y. Kim, and Y. M. Kim, “Design and fabrication of an underwater visualization rescue-rope,” Journal of the Korean Society of Marine Engineering, vol. 42, no. 9, pp. 767-771, 2018 (in Korean).

[https://doi.org/10.5916/jkosme.2018.42.9.767]

- W. H. Kim, G. M. Wang, G. S. Kil, D. J. Kim, B. W. Seo, S. Y. Kim and Y. M. Kim, “Visualization of a underwater rescue-rope using optical fiber,” Proceedings of the 42nd Korean Society of Marine Engineering Spring Conference, 2018 (in Korean).

- N. H. Kim, T. H. Kang, and G. S. Kil, “Railway Platform Safety Line using an Optical Fiber,” Proceedings of the Korean Society for Railway Fall Conference, pp. 110, 2019 (in Korean).

-

I. K. Kim, H. E. Cho, H. S. Kwon, H. G. Cho, and G. S. Kil, “Design guide of surface and watertight LED luminaires for naval vessels,” Journal of the Korean Society of Marine Engineering, vol. 35, no. 5, pp. 654-660, 2011 (in Korean).

[https://doi.org/10.5916/jkosme.2011.35.5.654]

- S. H. Kang and Y. S. Kim, “Effects of thickness and applied load on wear mechanisms of PMMA(Poly Methyl Methacrylate) coating layers,” Proceedings of the Korean Society for Technology of Plasticity Conference, pp. 152-155, 2004 (in Korean).

-

S. Abrate, R. Gaudino, and G. Perrone, “Step-index PMMA fibers and their applications,” Current Developments in Optical Fiber Technology, S. W. Harun, Croatia: IntechOpen, 2013.

[https://doi.org/10.5772/52746]

- CBT-90 Product Datasheet, PDS-001230 Rev 15, Luminus Devices, Inc., p.17, 2017. Available: https://download.luminus.com/datasheets/Luminus_CBT-90-W_Datasheet.pdf, .

- D. G. Kim, I. K. Kim, S. Y. Yu, W. Kwon, and G. S. Kil, “Comparative analysis on heat radiation of LED luminaires,” The Korean Society for Railway, pp. 1530-1535, 2011 (in Korean).