Electric analysis of solution plasma system for sterilization treatment of ship ballast sea water

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Although a number of techniques exist for eliminating underwater microorganisms, the application of energy waves generated by high voltage is known to be effective in removing bacteria in marine ballast water. Generating such a high voltage requires particular electrical devices. These devices may be subject to different characteristics of high voltage generation, depending on their constituent elements. Given that the parameters of each element are regarded an important design factor, the resistance, inductance, and capacitance can be considered as key elements for stabilizing the output voltage in the circuit. This study developed electric circuits using the PSIM program to understand plasma phenomena in solution, by analyzing the respective characteristics of high voltage with different electric elements. We obtained meaningful results from the simulation, in consideration of the adverse effects of damping, overshooting, and undershooting on those elements. It was also found that excess power consumption might diminish the efficiency of the system performance. In addition, the water conditions, particularly the salinity % and the temperature rise owing to the arc discharge, were revealed to contribute to changing the degree of resistance. Therefore, the research outputs are believed to offer insights to key elements for producing high-voltage characteristics that can improve the effectiveness of eliminating bacteria from ship ballast water.

Keywords:

PSIM, Ballast water treatment system, High voltage, Solution plasma, Electric modeling1. Introduction

The international rules and regulations pertinent to marine emissions have become stringent over recent decades [1]. While "emissions" in this context refers to various pollutions types, ballast water exchange activities during a voyage have been acknowledged as a major source of disturbance on the marine ecosystem [2].

According to ‘The Convention on the Management of Ballast Water’ by the International Maritime Organization (IMO), to prevent disturbances from alien species of coastal ecosystems owing to the ballast water of ships, vessels entering from foreign countries are required to exchange ship ballast water at a depth of 200 m or more [3][4]. Otherwise, microorganisms in ballast water must be eliminated by onboard ballast water management systems (BWMS). Table 1 shows the acceptable levels of bacterial emissions stated in the international regulations. The levels for US regulations are much more severe than those of the IMO [5]. In view of this, great efforts have been made to develop proper technologies to meet those regulations. To date, several types of BWMS have been introduced in the market, including UV treatment [6], indirect or direct electrolysis, ozone treatment [7], chemical compounds, and a plasma-arc method [8]. A solution plasma treatment [9]-[12] has drawn increased attention, as this method, which uses a high voltage discharge in the sea water, has been considered as a solution for the sterilization issue [13].

In this study, we introduce an electrical system that uses solution plasma to produce a high voltage which can create an acoustic wave and bubbles, thereby eliminating bacteria. Moreover, elements in the electric circuit are modeled and investigated, to determine their relationship with output voltage.

2. Overview of solution plasma

The basic concept of ‘in-liquid discharge’ describes a gas injection into ballast water. In this case, the insulation status matters. In that regard, either a low voltage given in a very close gap or a high voltage in a large gap allows electricity to pass through.

This is the insulation breakdown of the air. In high-voltage research, the materials are insulated against gas, solids, and liquids. For solids and liquids, once the insulation breaks down, it cannot be recovered. In contrast, the insulation effect of air can be restored. Such an insulation breakdown phenomenon depends on several system characteristics: the shape of the electrode, the distance between the electrodes, the applied voltage waveform, and the system type and arrangement. To perform such an in-liquid discharge, it is necessary to assess the stable operation state of the system, i.e., whether it can supply the high voltage successfully. In this study, we verified the effectiveness of the proposed electric circuit using the PSIM program. As this commercial program only provided low-level power sources, an additional power boost system was required.

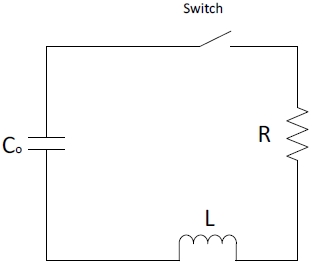

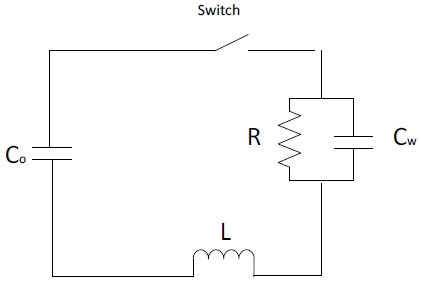

Figure 1 shows an example of a system with the electrical elements of one capacitor and a basic load. Switching on/off plays a role in changing the characteristics of the voltage applied to the load where the in-liquid discharge occurs. The voltage could be additionally influenced by the resistance and the inductance components in the circuit.

The magnitude of the output voltage required for high-voltage discharge can also be affected by the frequency of the input source, the resistance inductance, and the capacitance as shown in Equation (1) - Equation (12):

| (1) |

| (2) |

| (3) |

| (4) |

a) Over Damping

| (5) |

| (6) |

| (7) |

b) Critical Damping

| (8) |

| (9) |

c) Damping

| (10) |

| (11) |

| (12) |

2.1 The effects of elements on the electric system

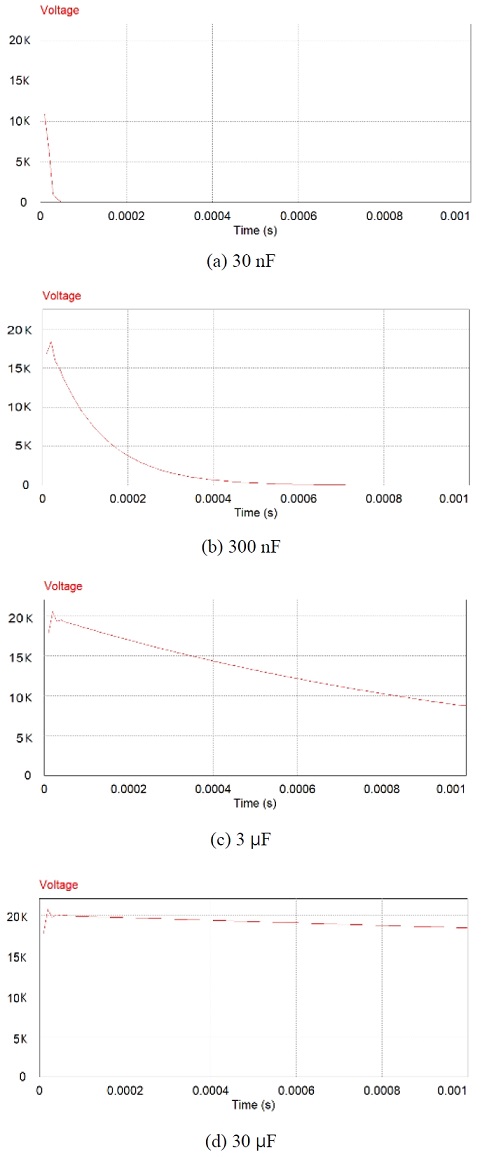

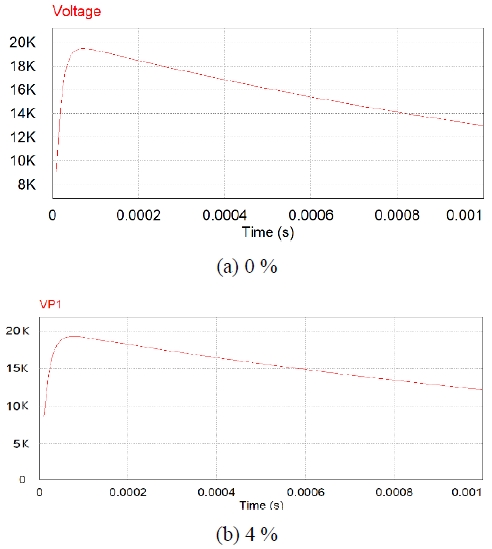

Figure 2 shows an electrical circuit where the effects of resistance, capacitance, and inductance on high voltage outputs can be considered. The PSIM program was used to perform simulations with different parameters. Tables 1 - Table 3 present the simulation parameters embodied in the PSIM program.

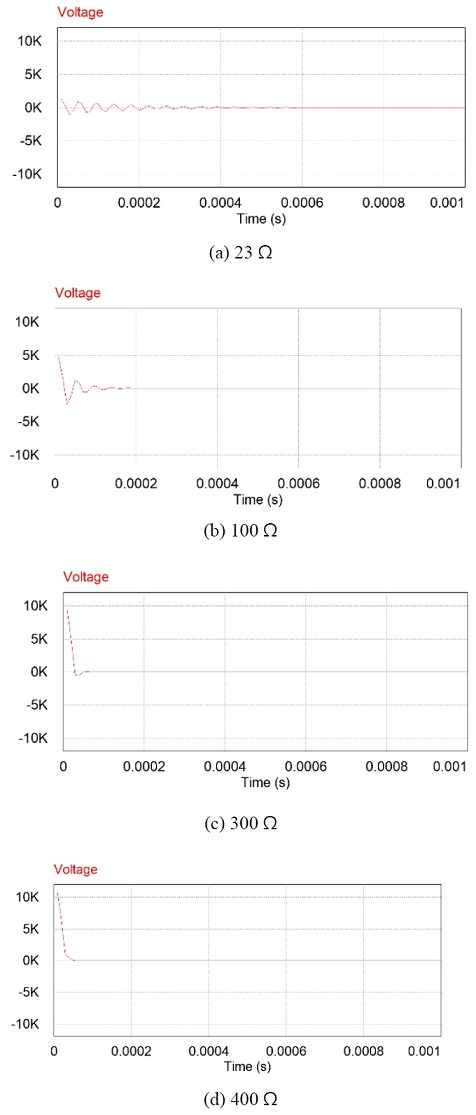

Figure 3 reveals that the magnitude of the resistance has a positive relationship with the maximum voltage output. A small resistance level appeared to generate a low level of voltage, and thus could not be considered to be a source unit value. Moreover, the effects of damping and undershooting made it difficult to discharge the arc. In addition, the resistance value was influenced by the change in temperature owing to the arc discharge, and the simulation results were also found to depend on the salinity of the solution.

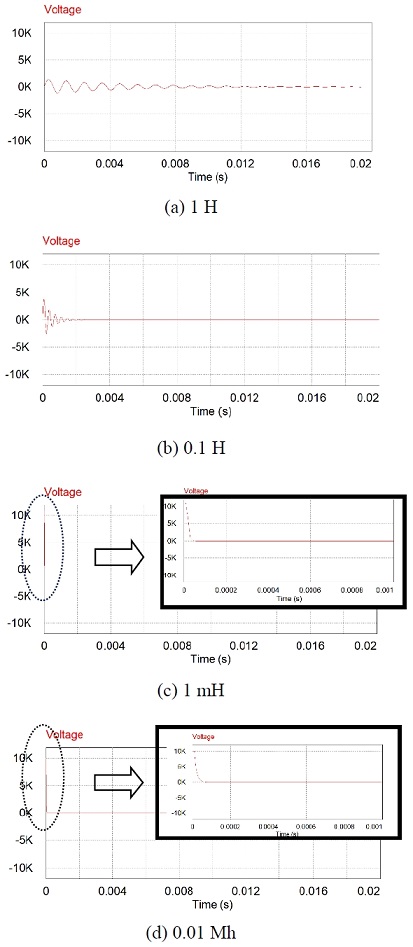

As shown in Figure 4, the inductance contributes to the stability of the entire circuit, and diminishes the damping effect of the voltage waveform. The peak voltage of output was significantly lower when high inductance values were applied to the simulations. High inductance values successfully led to generating a high level of output voltage, it but fluctuated rapidly. The simulation parameters are presented in Table 3.

As shown in Figure 5 (with Table 4 data), an increase in the magnitude of the power source capacity was found to prevent the drop in the voltage output. When the continuous voltage was applied to the circuit instead of the actual capacitor, the voltage drop was revealed to be insignificant.

3. Electric system for solution plasma

3.1 Schematic diagram of electric system for solution plasma

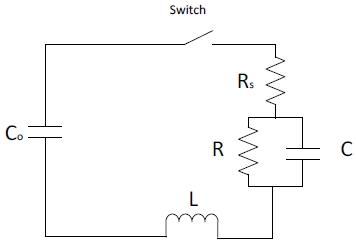

Unlike the electrical configuration described above, the circuit used for actual in-liquid voltage is shown in Figure 6. It was designed considering the resistance Rs owing to the solution characteristics, and the capacitance C1 and resistance R1 related to the charge transfer reaction occurring at the interface between the coating and the solution in the electric double layer.

4. Simulations & Experiments

To verify the high-voltage discharge characteristics of the solution plasma, the PSIM program was used with the circuit shown in Figure 7.

The output voltages were estimated in accordance with different resistances, capacitances, and inductance characteristics, by discharging the capacitor power once the switch was turned on. The values of each parameter used in the simulation are shown in Table 4, and the resistance values according to the salinity concentration of the solution are presented.

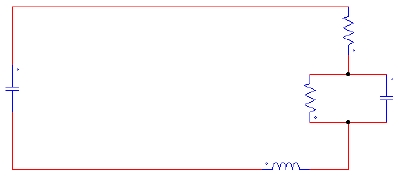

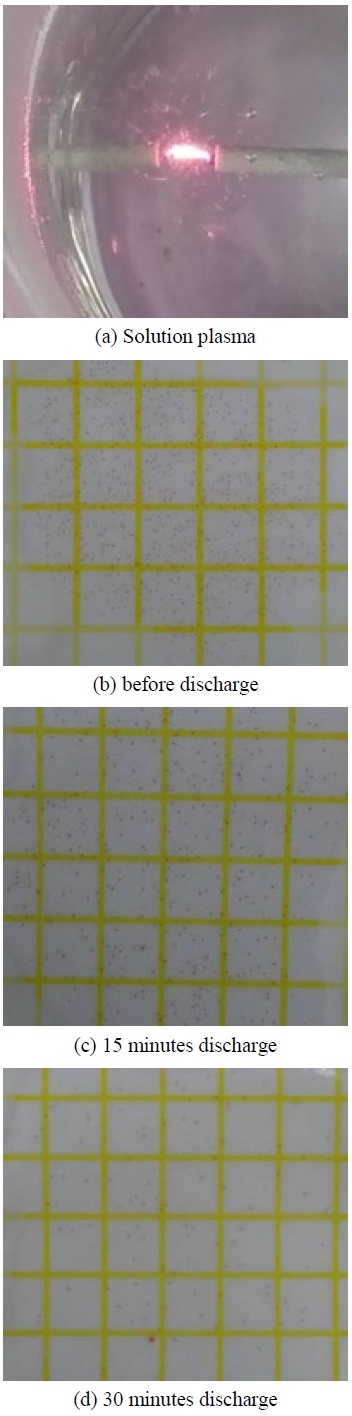

Figure 8 shows the rise and fall of the output voltages according to the varying solution resistances and the resistance and capacitance values in the electric double layer. To investigate the sterilization effect by solution plasma in sea water, an arc discharge was introduced for up to 30 minutes, as shown in Figure 9 (a). The plasma process was performed under conditions of 8 kV, 30 kHz, and 1L of seawater, using a pointto-point probe. After discharge, the bacteria were diluted 1000 times with pure water, and were cultured at 35 ± 1 ° C for 48 hours on 3M Petrifilm dry rehydratable film media. The research results revealed that the cultured bacteria had decreased from approximately 55 ± 5 to 20 ± 5, and 8 ± 2 cfu/cm2 during the discharge time. This sterilization effect was attributed to the high voltage in-liquid discharge [10], as well as effects of UV light [6]. Thus, this study demonstrated the effectiveness of sterilization phenomena by an arc discharge treatment system using solution plasma. However, control of the initial discharge parameters in the solution plasma is difficult, and further studies regarding the correlation between the simulation data and actual discharge phenomena in the initial discharge time are necessary.

5. Conclusion

A solution plasma discharge was performed for ship ballast sea water treatment, and its high performance on sterilization was presented. To investigate the high voltage discharge, we analyzed the electric system and the electric characteristics of the electrode circuit using the PSIM program. From the simulation results, we demonstrated the initial discharge conditions in several liquid solutions, e.g., the salinity, resistance, inductance, and capacitance. The consideration of a source unit by calculating the electricity consumption for equipment and the values of inductance, resistance, and capacitance could cause damping, undershooting, and overshooting effects on the output voltage, which adversely influence the magnitude of the arc discharge. Moreover, it was found that high power consumption could lead to inefficient system performance, and that the water conditions of the salinity % and the temperature rise owing to the arc discharge could lead to a change in resistance level. Moreover, normal operating ranges for using solution plasma could be determined. Thus, this study demonstrated the effectiveness of the sterilization phenomena by an arc discharge treatment system using solution plasma.

Acknowledgments

Author Contributions

Methodology, J. Kang and Y. Yun; Software, S. Kim; Validation, Y. Yun; Formal Analysis, J. Kang and Y. Yun; Investigation, Y. Yun; Resources, J. Kang; Data Curation, J. Kang; Writing—Original Draft Preparation, S. Kim; Writing— Review & Editing, J. Kang and S. Kim; Visualization, Y. Yun; Supervision, J. Kang; Project Administration, Y. Yun.

References

-

Ø. Endresen, H. L. Behrens, S. Brynestad, A. B. Andersen, and R. Skjong, “Challenges in global ballast water management”, Marine Pollution Bulletin, 48(7-8), p615-623, (2004).

[https://doi.org/10.1016/j.marpolbul.2004.01.016]

-

E. Tsolaki, and E. Diamadopoulos, “Technologies for ballast water treatment: a review”, Journal of Chemical Technology and Biotechnology, 85(1), p19-32, (2010).

[https://doi.org/10.1002/jctb.2276]

-

M. Basuki, Lukmandono, and M. M. Z. Beu, “Implementation IMO regulation of ballast water management at Inaport 2nd Jakarta based environmental risk assessment”, Materials Science and Engineering, 462, 012044 (2019).

[https://doi.org/10.1088/1757-899x/462/1/012044]

- A. L. Curto, P. Stehouwer, C. Gianoli, G. Schneider, M. Raymond, and V. Bonamin, “Ballast water compliance monitoring: A new application for ATP”, Journal of Sea Research, 133, p124-133, (2018).

-

Y. C. Lee, and W. J. Ha, “A study on the development of ballast water management-related familiarization training pursuant to the STCW convention”, Journal of the Korean Society of Marine Engineering, 41(2), p163-170, (2017).

[https://doi.org/10.5916/jkosme.2017.41.2.163]

-

S. G. Cheon, D. W. Park, and G. S Kil, “Development of an ultra-violet lamp and a ballast for ship’s ballast water treatment”, Journal of the Korean Society of Marine Engineering, 35(5), p675-681, (2011), (in Korean).

[https://doi.org/10.5916/jkosme.2011.35.5.675]

-

S. J. Park, K. W. Kim, and I. S. KIM, “Shipboard test of ballast water treatment system by ozonation”, Journal of the Korean Society of Marine Engineering, 34(3), p391-398, (2010).

[https://doi.org/10.5916/jkosme.2010.34.3.391]

- M. David, and S. Gollasch, Global Maritime Transport and Ballast Water Management, Springer, (2015).

- J. S. Chang, S. Ono, H. Ukai, Y. C. Huang, W.Y. Chang, P. Shou, M. Sato, S. Teii, C. Liu, and K. Ting, “UV and optical emissions generated by the pulsed arc electrohydraulic discharge”, International Journal of Plasma Environmental Science & Technology, 1(2), p130-134, (2007).

-

T. Kaneko, and R. Hatakeyama, “Controlled gas–liquid interfacial plasmas for synthesis of nano-bio-carbon conjugate materials”, Japanese Journal of Applied Physics, 57, 0102A6 (2018).

[https://doi.org/10.7567/jjap.57.0102a6]

-

N. Saito, M. A. Bratescu, and K. Hashimi, “Solution plasma: A new reaction field for nanomaterials synthesis”, Japanese Journal of Applied Physics, 57, 0102A4 (2018).

[https://doi.org/10.7567/jjap.57.0102a4]

-

A. Watthanaphanit, and N. Saito, “Solution plasma applications for the synthesis/modification of inorganic nanostructured materials and the treatment of natural polymers”, Japanese Journal of Applied Physics, 57, 0102A3 (2018).

[https://doi.org/10.7567/jjap.57.0102a3]

-

O. Takai, “Solution plasma processing (SPP)”, IUPAC, Inetrnational Union of Pure and Applied Chemistry, 80(9), p2003-2011, (2008).

[https://doi.org/10.1351/pac200880092003]