Thermal performance and economic analysis of gas turbines operating in a hot climate-Kuwait

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Gas turbines are the main source of generating power in Kuwait. There are various cycles in which they operate. Open cycle gas turbines, located in the LM6000 and Frame Seven units of the Kuwait Power Plant in Subiya, Kuwait, generate a considerable amount of power for the city of Kuwait. One of the main concerns about these turbines is their overall efficiency during hot and humid weather. This paper investigates an economic method of improving the output efficiency of gas turbines in this type of climate. The efficiency of gas turbines in the Frame Seven unit at the peak air temperature and humidity was determined as 34%. Subsequently, a conceptual gas cycle was analyzed by adding a cooling system to air intake of the turbine and this increased the efficiency by of 2%. Moreover, an economic analysis supported the feasibility and cost efficiency of installing a centrifuged chiller. A thermal analysis of the suggested gas cycle was performed to study the increase in the thermal efficiency by modifying the cycle and adding a chiller to cool down the hot inlet air during the summer. The results showed that power generation improved and the cost of maintenance was reduced due to the possible damages caused by hot and humid air to the compressor blades.

Keywords:

Gas turbine, Chiller, Thermal analysis, Economic analysis1. Introduction

Power plants are extensively used to generate electricity. Worldwide, power plant equipment manufacturers intend to increase the efficiency of their systems so that a minimum amount of fuel is consumed to achieve the maximum possible output [1].

This can be achieved by improving thermal cycles of power plants by adding components such as heat exchangers, boilers, fans, and condensers, and by varying input parameters at different stages, such as increasing air or water inlet temperature and making use of all consumed energy. However, owing to the high investment cost in most cases, power plant companies do not consider modifying their systems.

In this study, two actual gas turbine units located in the Kuwait Power Plant are considered. The two gas turbines units are the LM6000 (Land and Marine) and the Frame Seven.

The LM6000 gas turbine is modified by adding a chiller to the cycle to obtain the maximum possible output from the system. By adding a chiller to the system, the turbine can operate efficiently during harsh summers in Kuwait,, when temperature reaches 50 degrees Celsius [1]. However, turbines in the Frame Seven unit are not designed to operate in such a hot climate. Therefore, during the summer, the efficiency of the gas turbines decreases rapidly. Ideally, the system output should be 100 MW at full capacity [2], but the output reduces to 75 MW. Consequently, the operating companies suffer huge energy and profit losses. Based on this information, the aim of this paper is to evaluate the modification of the cycles of the two gas turbine units located in the Kuwait Power Plant, and to increase their efficiency and thermal performance so that they can operate in a hot and humid climate.

2. Data Collection

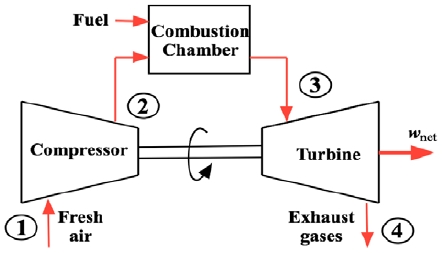

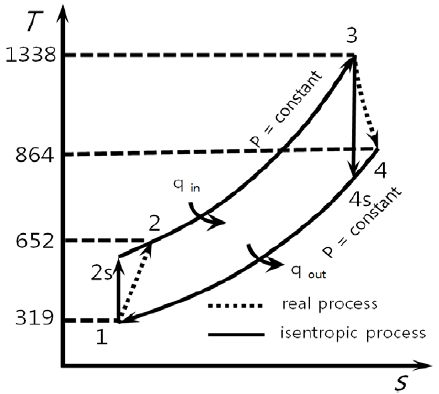

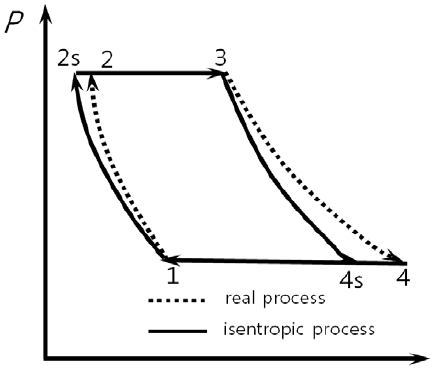

Data was collected from the control panel located at the heart of the power plant. The gauge readings at different stages are presented below. It should be noted that data was collected in July 2015, which is an early summer time in Kuwait with daily temperature increasing rapidly. Figure 1 shows different stages of the operation of an open cycle gas turbine power plant, and Figure 2 and Figure 3 show the actual data associated with each step [3].

At stage 1, the fresh air is drawn into the gas turbine (Figure 1) and compressed in the compressor as shown by 1-2 (Figure 2). This causes an increase in pressure from the atmospheric pressure of approximately 1 bar to the outlet compressor pressure, shown by 2 (Figure 3). Additionally, the volume of the gas reduces as shown by 1-2 [3] (Figure 3). The air temperature measured in July 2015 at 1:30 PM was 319 K. After the air compression, the temperature increases to 625 K.

In the next stage, the combustion of gases takes place at a constant pressure in a combustion chamber. During this stage, the temperature increases rapidly from 652 K to 1338 K. The pressure in the combustion chamber remains constant at approximately 9.7 bar, whereas the gas volume increases, as illustrated in Figure 3.

At stage 3, hot gases resulting from the combustion exit the combustion chamber, enter the turbine, and rotate the blades. The turbine blades drive a shaft that rotates an electrical generator [4]. During this stage of isentropic expansion (shown by 3-4; Figure 2), the temperature decreases from 1338 K to 846 K (T min). The pressure also reduces dramatically [3][4]. As mentioned earlier, by reducing the turbine outlet temperature, its efficiency can be increased. For this reason, cooling systems are placed in the turbine at this stage to increase its efficiency.

The final stage according to the ideal Bryton cycle is the heat rejection, in which exhausts from the open cycle gas turbine is released into the atmosphere (instead recycled in a closed loop system), and fresh air is drawn into the system [3][4].

3. Thermodynamic Calculations and Discussion

The open cycle gas turbine was assumed to be a closed cycle gas turbine for the purpose of performing numerical analysis and calculations [3]. All of the required data from the Frame Seven unit in the power plant was collected, and thermodynamic calculations were performed to determine the efficiency. It should be noted that the calculations were simplified to focus on the objective of the paper, which is to determine if installing a chiller in the Frame Seven unit is economically feasible and would increase its efficiency. The calculations used in this study are presented below.

The following enthalpies of air were extracted from temperature–enthalpy thermodynamic charts for specified temperatures. The air temperature was 319 K (46 °C) at the time it entered the compressor.

T1 = 319K → h1 = 319.286 kJ/kg

| (1) |

319ⅹ(9.7/1)0.4/1.4=610.6K → h2s = 618.16 kJ/kg

T2 = 652K → h2=661.966 kJ/kg

T3=1338K → h3=1441.216 kJ/kg

T4=846K → h4=872.737 kJ/kg

| (2) |

1338ⅹ(1/9.7)0.4/1.4=699.1K → h4s=712.3 kJ/kg

The works and isentropic efficiencies of the compressor and the turbine were calculated as follows.

| (3) |

661.966−319.286=342.68 kJ/kg

| (4) |

1441.216−872.737=568.479 kJ/kg

| (5) |

| (6) |

The heat transfer rate during the combustion process and the thermal efficiency of the gas turbine were calculated as follows.

| (7) |

| (8) |

According to the Bryton ideal cycle calculations, the efficiency of the Frame Seven gas turbine was determined to be 28.9%, based on the data collected at the specified date and time. Figure 4 below shows the Frame Seven gas turbine unit of the Kuwait power plant.

Consequently, the need for a centrifugal cooling system to reduce the temperature of the inlet air introduced into the system was predicted. Hence, it was necessary to analyze a new cycle using cooled inlet air to the compressor and observe changes in the thermal efficiency [5][6].

According to the chiller specifications, a centrifugal chiller duplex model CDHG with compressor size of 2150 ton and motor frequency of 50 Hz can reduce the air temperature to 280 K. Therefore, based on an inlet temperature of 280 K (approximately 6.8 °C), the efficiency of the gas turbine cycle was determined and is presented below. The air temperature was changed from 319 K (approx. 46 °C) to 280 K (approx. 6.8 °C), which is a decrease of 39.2 K.

T1 = 280K → h1 = 280.13 kJ/kg

T2s = 280 (P2/P1)(k−1)/k

280ⅹ(9.7/1)0.4/1.4=535.9K → h2s = 540.09 kJ/kg

Assuming that the compressor had a constant isentropic efficiency,

| (9) |

578.18kJ/kg → T2 = 572.47K

Assuming the same heat transfer rate of the combustion chamber,

| (10) |

578.18+779.25=1357.43kJ/kg → T3=1266.35K

T4s = T3 (P1/P2)(k−1)/k

1266.35ⅹ(1/9.7)0.4/1.4=661.63K → h4s=672.2kJ/kg

Assuming the same isentropic efficiency of the turbine,

| (11) |

1357.43−(1357.43−672.2)0.77989=823.02kJ/kg → T4=800.97K

Works of the compressor and the turbine were calculated as

wcomp, in=h2−h1=598.18−280.13=298.05 kJ/kg

wturb,out= h3−h4=1357.43−823.02=534.41 kJ/kg

The thermal efficiency of the gas turbine was calculated by assuming the constant heat transfer rate during the combustion process.

qin =h3−h2=(1357.43−578.18)=779.25kJ/kg

As expected, based on an LM6000 gas turbine cycle, which uses a cooling system for the inlet air introduced into the compressor, the analysis of a new cycle for the Frame Seven turbine cycle showed that a reduction in the inlet air temperature of the system slightly increased the cycle efficiency. The table below shows the comparison of both calculations.

According to thermodynamic calculations, a reduction in the temperature of the inlet air introduced into the compressor increased the overall efficiency by 2%. In addition, adding a chiller to the system lowered the chance of damage to the compressor blades due to high air temperature and humidity. It is worth noting that in modern gas turbines, internal cooling systems are used for the compressor and turbine blades to avoid excessive temperatures [5].

The chiller that reduced the air temperature from 319 K to 280 K resulted in huge advantages for the power plant, including a reduction in maintenance costs and an overall increase in the power generation. However, it was vital to consider an economic analysis of installing chillers for all four gas turbines present in the Frame Seven unit.

4. Proposed Chiller Design

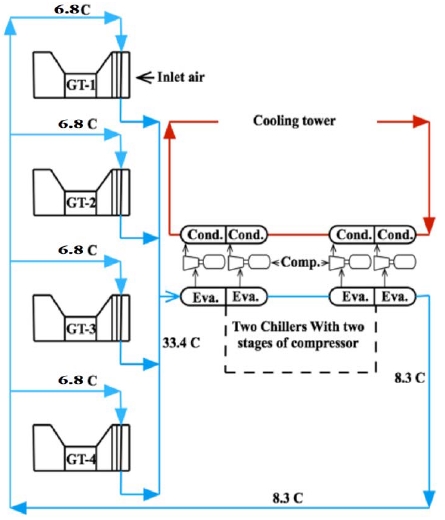

After cycle efficiency calculations in the real-time operation mode of the Frame Seven gas turbine unit, a reduction in the inlet air temperature was determined to improve the efficiency. A chiller proposed to reduce the air inlet temperature is presented below.

It was decided to add a cooling coil into the air inlet gate of the gas turbine cycle, which will improve the efficiency of the compressor and the entire system. Hence, a chiller unit was designed and installed, which reduced the air temperature to 280 k (approx. 6.8 °C). It should be noted that the chiller design was taken from module LM6000 [1], and the same data was applied to the Frame Seven turbine unit.

As shown in Figure 5, there are four gas turbines in the Frame Seven turbine unit. The refrigeration cycle and cooling towers are placed parallel to the inlet gate of the compressor. The inlet temperature remains constant at 280 K (6.8 °C) during the summer in Kuwait, which means no loss of efficiency and an increased load on the power plant.

5. Chiller Cost Analysis

To assess the investment and installing of a chiller, different methods can be used. The method utilized in this project is the life cycle cost (LCC) analysis. It is possible to compare various possible chiller systems using this method.

Cost calculation of heating, ventilation, and air conditioning (HVAC) includes acquisition costs, energy costs, and maintenance costs. The acquisition cost is based on the first cost alternative. The energy cost is determined annually using an 8760 hour-by-hour energy-modelling program. The annual maintenance costs are determined, on the basis of normal and recommended maintenance.

The LCC is determined as follows:

LCC = acquisition costs + energy costs + maintenance cost

For investment, economic assumptions of the following parameters should be taken into consideration: exchange rates, no value added tax (VAT) included in chiller, energy, and labor prices, 2% energy and labor inflation, no purchase price inflation, no currency inflation, and a minimum attractive rate of return of 5%.

6. Economic Analysis

The results of designing and adding a chiller to a system in which air enters the turbine’s compressor show an efficiency increase of 2%. In this study, it is investigated whether a 2% increase in overall efficiency of each turbine is worthwhile, or it is better to consider alternatives for increasing the turbine efficiency during summer.

The Frame Seven has four gas turbines that contribute to power generation in Kuwait City. Each turbine has an efficiency of approximately 28.9% during critical hot times and peak air temperatures in summer. Adding a cooling system to reduce air temperature during hot humid summers in Kuwait City will increase the thermal efficiency of each turbine to 30.9%.

It should be noted that 34% efficiency is during the peak air temperatures of the summer in Kuwait. Therefore, it is considered as the minimum efficiency of the system in a year. An increase of 2% in the efficiency of each turbine by adding a cooling system is also for peak air temperatures. Hence, adding a cooling system to each gas turbine increases the efficiency of the Frame Seven turbine unit by 8%, as the Frame Seven consists of four gas turbines

According to the data collected from the control room unit of the Frame Seven, the fuel consumption of each turbine at a given time (July 2015) is 4.8 kg/s or 17.28 ton/h. Hence, the Frame Seven unit consumes 19.2 kg/s fuel in total.

The fuel used for the gas turbines is diesel with a density of approximately 0.832 kg/L (6.943 lb/US gal). This is approximately 11.6% greater than the density of ethanol-free petrol (gasoline), which is approximately 0.745 kg/L (6.217 lb/US gal). In SI units, 1 kg/s diesel is approximately 1.3 L/s. Hence, the fuel consumption of each turbine is 5.423 L/s. For the four turbines of the Frame Seven turbine unit, the total fuel consumption is 21.692 L/s.

According to the diesel fuel price in Kuwait (July 2015), each liter of diesel costs 150 Fils. It should be noted that the price of fuel in Kuwait is fixed and managed by the government. According to the currency exchange rate:

Date: 5th August:

1 Kuwait dollar (KWD) = 2.107 British Pound (BP)

1000 Fils = 210 Pence

1 Fils = 0.21 Pence

Each KWD is divided into 1000 Fils and each BP is divided into 100 Pence. According to the currency exchange rate, each Fils equals 0.1 British pence, and approximately 0.21 Pence. Since the price of diesel fuel is 150 Fils per liter, the price of diesel consumption of each gas turbine will be 31.5 Pence per liter.

As mentioned before, the fuel consumption of each turbine is approximately 5.423 L/s and of all turbines is 21.692 L/s. Thus, the fuel costs 1.708 BP for each turbine. Each turbine consumes 5.423 L/s × 3600 s = 19522.8 L/h or 468547.2 L/d.

Therefore, the cost of the fuel consumption of each turbine is 5.423 L/s × 1.708 BP = 9.262 BP L/s or 33,345 BP L/h or 80,280 BP L/d.

At an efficiency of 34%, each turbine generates 80 MW/h (80,000 kW/h) of electricity. Each Kilowatt-hour of electricity is sold for 2 Fils, which is approximately 0.42 Pence. Therefore, the power generation by each turbine in the Frame Seven costs 80,000 × 0.42 = 33600 Pence = 336 BP per hour. Consequently, the total cost of power generation by four turbines of the Frame Seven costs 336 × 4 = 1344 BP per hour.

According to the above calculations, the hourly cost of the fuel consumption of each turbine to generate 80,000 kW power is 33,345 BP, whereas the power generated is sold for only 336 BP. This implies that the government of Kuwait subsidizes the power sold to consumers by 99.2%. It should be noted that this is only based on the price of fuel consumption and the selling price of electricity. In addition to the price of fuel, there are various additional costs of operating a power plant, which are considerably high.

By referring to the thermodynamic analysis of the Frame Seven gas turbine cycle, it can be concluded that adding a cooling system, using a centrifugal chiller, to the inlet section of the turbine reduces the inlet air temperature by 40 °C and increases the efficiency of each turbine by 2%. In this section, an attempt is made to convert this increase in efficiency into the power generation potential of the power plant and thus determine the profit achieved.

Each turbine generates 80 MW of power with 34% efficiency. A 2% increase in the efficiency equates to 4.7 MW of power per hour.

According to the cost analysis in this study, the price of each kilowatt is 2 Fils. Therefore, the efficiency increase equates to 4700 kW/h × 2 Fils = 9400 Fils or 19.74 BP savings per hour for each turbine. Considering 99.2% government subsidies, the actual savings after increasing the efficiency will be 1954 BP per kW/h for each turbine.

For the Frame Seven with four turbines, the overall additional power generated is approximately 20 MW per hour for only 2% increase in efficiency and an increase in the profit of the power plant to approximately 8000 BP per hour.

There are various factors in the economic analysis of a system. In this project, an attempt was made to focus on the main parameters and give a broad idea of approximate changes in power plant profit by making changes to the system. Moreover, maintenance costs will dramatically drop due the reduced risk of malfunctions.

7. Conclusions

After a proper literature review and study of all the provided manuals of the LM6000 and the Frame Seven gas turbine cycles from the Kuwait Power Plant, required data were collected from the control panel of the Frame Seven to analyze the efficiency of the system at peak temperatures and humidity in the region. Then, the system performance was analyzed with a potential cooling system and the efficiency gain for the system was determined.

As a result, the efficiency of each turbine in Frame Seven was determined to be 28.9% during peak temperature and humidity conditions when the efficiency dramatically drops. By adding a cooling system and determining the resulting system efficiency, a 2% efficiency increase was achieved, and the efficiency reached 30.9%. Therefore, from a thermodynamic point of view, it is wise to add an air-cooling system to the Frame Seven turbines.

The price of fuel, gas turbine fuel consumption, and the price of electricity by factoring in the government subsidies were determined. The results showed that adding an air cooling system will be a suitable option for increasing the efficiency of the turbines, and, importantly, can reduce the damage to the system.

As a result of an economic analysis, it was found that an efficiency increase of only 2% could result in the overall increase of 20 MW/h power generation.

References

- A. Ghanim, LM6000 Gas Turbine-Generator Package Familiarization Training Course,. GE Energy, Kuwait, International Sabiya-Kuwait, (2008).

- G. P. Systems, GE Frame 7 EA Gas Turbine Training, Kuwait, Ministry of Electricity and Water (MEW), (2008).

- Y. A. Çengel, and M. A. Boles, Thermodynamics: An Engineering Approach (5th ed.), New York, NY, McGraw-Hill Education, (2004).

-

J. R. Simões-Moreira, “Fundamentals of thermodynamics applied to thermal power plants”, Escola Politécnica da USP, (2012).

[https://doi.org/10.1007/978-1-4471-2309-5_2]

- J. W. Stewart, Design Guide: Combustion Turbine Inlet Air Cooling Systems (Final Report, RP-902), Atlanta, American Society of Heating, Refrigerating and Air-Conditioning Engineers, (1997).

- J. A. Ebeling, “Combustion turbine inlet air cooling alternatives and case histories”, Proceedings of the 27th Annual Frontiers of Power Conference, pX-1-X-6, (1994).