Design and preliminary experimental testing of a water harvester using the Peltier effect

Copyright ⓒ The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

This paper discusses the fabrication and testing of a portable device that facilitates harvesting water from air under different operating conditions. The objective of designing a water harvester that relies on solar energy by using thermoelectric power and Peltier structure has not been fully realized. This study demonstrates that the quantity of water generated by the device is related to the relative humidity and difference between the air and cooling-surface temperatures. Testing performed in Kuwait generated 715 g of water over a period of 24 h. This result implies that hot and humid environments, such as those in the Middle East and North Africa, would greatly benefit from the present water-harvesting system.

Keywords:

Water harvester, Solar energy, Thermoelectric power, Peltier structure1.Introduction

Water is an essential element of life, and without it, civilizations cannot survive. The global water supply has rapidly diminished over the past few decades due to population growth and increased urbanization [1]. Urban population growth has outpaced the relatively slow development of new infrastructure [2]. Consequently, a significant amount of capital funding and energy are required to convert pond water and sewage wastewater into fresh water [3]. Some countries are facing this challenge on a much larger scale than others; arid areas in the Middle East and Africa are amongst the driest regions on Earth inhabited by humans [4]. Some desert habitats exist near the coast, and the inhabitants can therefore desalinate seawater to generate fresh water [5]. However, in areas that lie further inland from the coast, it is necessary to find creative solutions to the water-shortage problem.

The increasing recognition of the harmful effects of fossil fuels has encouraged the search for renewable energy-based solutions [6][7]. As such, large-scale, energy-intensive desalination projects may not represent the best solution to the problem of limited water supplies [8]-[10]; the power supply may be as limited as the water supply. Utilization of carbon-based energy resources could therefore work against the objective of sustainably generating sufficient volumes of water. This is because carbon emissions resulting from energy production tend to cause irreversible changes in the atmosphere [11]. As such, the negative consequences of the non-renewable, energy-based, water-generation processes far outweigh the benefits that could be obtained.

The ubiquity of renewable-energy devices offers a huge incentive for the use of green technology. The proliferation of solar cells in the modern-day market has drastically reduced the cost of using such technology [12]-[14]. This development has allowed green technology to become more accessible to the common person than it was a decade ago. In addition, the drive to innovation incorporating various solar-powered devices has never been as intense [15][16]. The economic promise of renewability, particularly in areas where solar energy is plentiful, facilitates the use of the so-called “desert power” of arid regions [17] to ensure sustainability [18].

In view of the declining water supply and rising economic favorability of solar photovoltaics (PVs), a renewable solution, harvesting water from air, becomes viable. This study discusses the fabrication and performance characterization of a portable water harvester. An experimental analysis was performed to test the unit and attempts were made to identify the parameters that influence the quantity of water generated by water harvester. These parameters were identified as the three atmospheric conditions of relative humidity (RH, %), air temperature (°C), and cooling-surface temperature (°C). The data analysis presented herein investigates the implications of the obtained results on the scalability of the water harvester prototype.

2.Methods

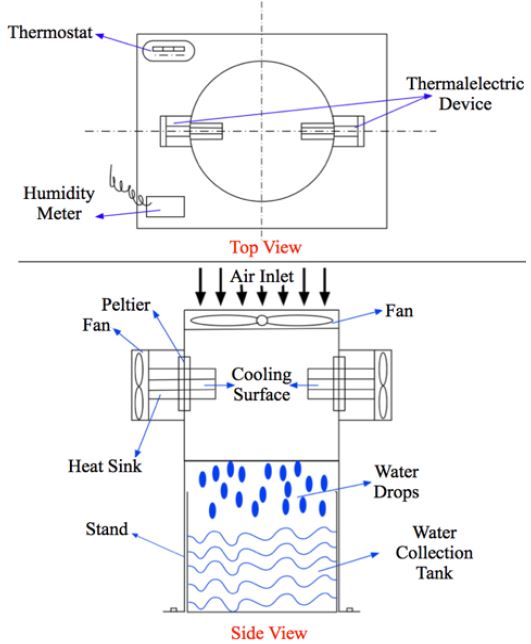

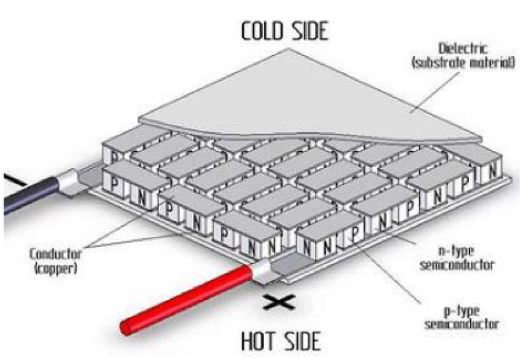

The water harvester prototype depicted in Figure 1 was designed using standard engineering design principles. The design was based on the phenomenon of direct-to-air thermoelectric cooling, which has many uses, including heating, cooling, and even power generation [19]. The power-generation application relies on the Seebeck effect [20], which facilitates the conversion of thermal energy into electrical energy. Through manifestation of this effect, the device can effectively recover some of the wasted heat [19]. The standard contemporary water harvester design utilizes a thermoelectric power generation module operating in reverse [21]. That is, instead of generating electricity from heat, electricity is, in turn, used to generate heat. This heat generation consequently serves to cool the surface down through another phenomenon known as the Peltier effect [22], the highlight of an earlier patent [23]; as one junction of a Peltier structure heats up, the other cools down.

Figure 2 depicts the Peltier structure with copper conductors sandwiched between p- and n-type semiconductor materials. Other parts used in the water harvester construction, such as thermostat and humidity meters, were integrated through digital sensors and controllers. The device was constructed using transparent PVC plastic. The fans that supply air, thereby heating up the exposed (interior) side of the Peltier structure, provide the necessary cooling function. Air from the fans is supplied from above and water vapor is condensed by the colder region within the Peltier structure. The condensate drops to the bottom of the silo, where it is collected inside a water-collection tank. Over time, the level of water increases as more condensate accumulates inside the tank.

A digital humidity meter (installed on top of the water harvester) enables automated measurement of RH. A thermostat, on the other hand, implements digital control and regulates the cooling temperature near the dew point. At the dew point, the water vapor in the air condenses into water at barometric pressure. The cooling region, therefore, facilitates phase transformation, which leads to the formation of dew drops.

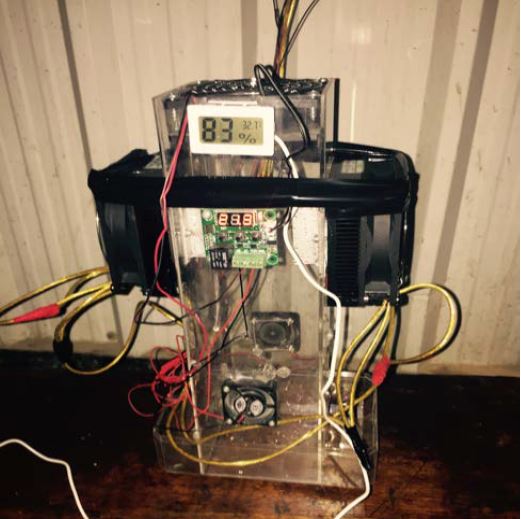

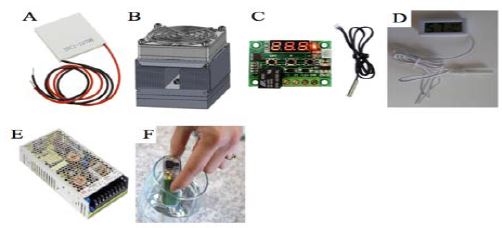

The present water harvester system is entirely self-sustaining as it draws power from solar energy. The total power requirement of the system is approximately 23 W. Solar PV cells supply electrical energy to the battery for power storage, thereby facilitating 24-h operation of the system even if sunlight is only available for a fraction of the day. The individual components of the water harvester are shown in Figure 3.

Individual components of the device (a) Peltier structure; (b) Direct-to-air thermoelectric cooling system; (c) Digital thermostat; (d) Humidity meter; (e) Power adaptor; (f) UV filter

An experiment was performed in Kuwait over a 24-h period to demonstrate the functioning of the contemporary system. The aim of the experiment was to investigate factors that govern the total quantity of water generated by the water harvester. Intermediate results and changes in environmental conditions during the experiment were recorded at 2-h intervals, chosen because the prototype container for water collection was small. Without the help of data acquisition systems, temperatures and the relative humidity were measured. The average values were recorded by hand every 2 h. Figure 4 and Figure 5 below depict the experimental set up.

3.Results

The experimental conditions were designed to observe the functionality of the water harvester. As already mentioned, the experiment was performed in Kuwait on a typical day, under conditions where the ambient air temperature was between 32–39 °C and there was 75% average relative humidity. During the experiments, humidity ratios remained almost constant.

The results of the 24-h experiment are presented in Table 1. It can be observed that the amount of water increased significantly when the air temperature and RH increased.

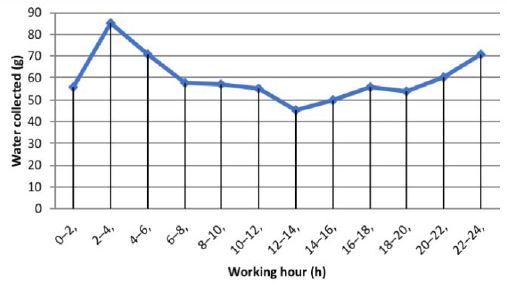

The first analysis of the system was related to the time of operation and the amount of water collection. As depicted in Figure 6, approximately 60 g of water was collected within the first two hours of the experiment, considered a good start. Over the next two hours, the graph shows peak water collection (more than 80 g). Over the next 10 hours of operation (i.e., 4–14 h), the amount of water collected exhibits a downward trend, and achieves a minimum value. Subsequently, an increase in water collection can be observed, and the amount of water collected in the last two hours of the experiment increases to approximately 70 g.

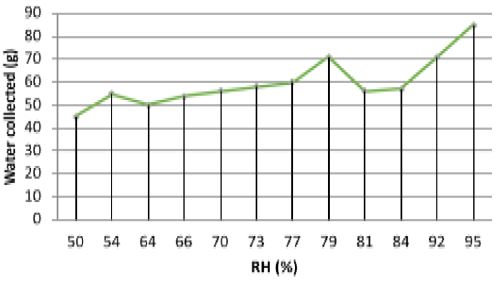

The next analysis investigates the variation in the amount of water collected with changes in relative humidity during the daytime.

The experimental data were recorded from 1:00 AM on the first day until 1:00 AM the following day. During this time, the relative humidity demonstrated minimum and maximum values of 50% and 95%, respectively. Figure 7 depicts the variation in water collected with respect to changes in the relative humidity. As seen in the figure, the amount of water collected increases with increases in the relative humidity, and this trend continues up to the maximum RH value of 95%. It can therefore be concluded that an increase in the RH value leads to the collection of a greater quantity of water.

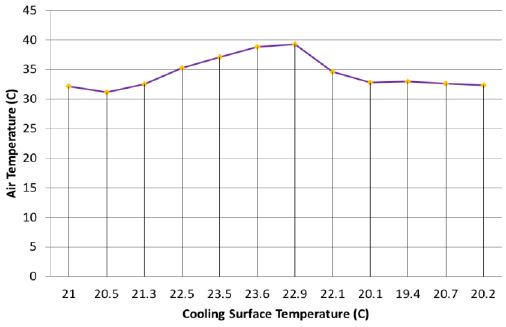

Lastly, we performed an analysis to investigate the relation between the cooling-surface and ambient air temperatures. Figure 8 depicts this trend in the form of a line graph, wherein an increase in the ambient air temperature leads to a corresponding increase in the cooling-surface temperature, and vice versa.

The above figure demonstrates that the air temperature has a direct relationship to the power consumed in reducing the temperature of the cooling surface. As such, the airflow could be utilized to control the temperature of the cooling surface.

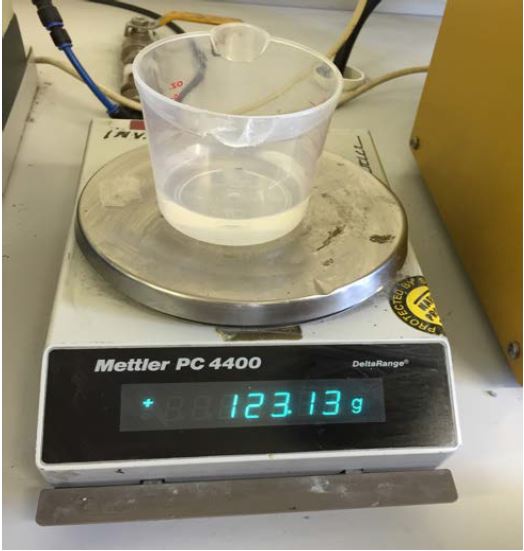

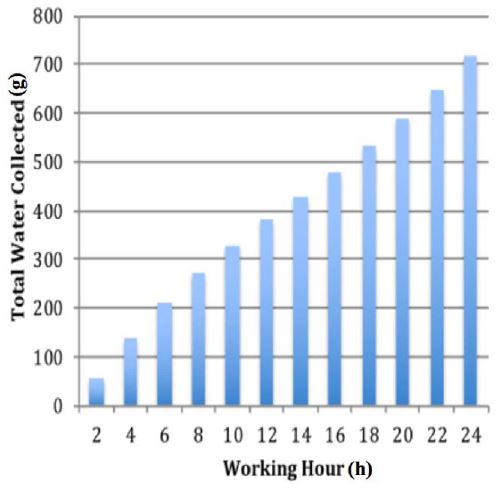

After 24 h of operation, the device had collected a total amount of 718 ml of water, which is enough for human survival in the event of an emergency until further help arrives. This result is depicted in Figure 9.

4.Conclusion

The study demonstrates that the quantity of water generated by the present water harvester varies significantly with changes in relative humidity, as well as the difference between the air and cooling-surface temperatures. The present water harvester model was found to perform better in terms of generating water from atmospheric air over a specific period, under conditions of high relative humidity with a large difference between the air and cooling-surface temperatures. Therefore, the present water harvester model is most suitable for application in hot and humid regions of the world, such as Kuwait.

The following are proposed to be undertaken by the authors as part of future research endeavors. Firstly, the authors intend to design a solar panel to power the water harvester, although the device has been designed to consume the minimum possible power.

The number of cooling surfaces employed could be increased from 2 to 4 to increase the amount of water vapor that undergoes condensation. It must, however, be noted that increasing the number of cooling surfaces would concomitantly increase the power consumption.

It is also possible to modify the design, thereby reducing the size of the unit and enhancing its portability. Future research could focus on improving the external design of the unit.

A commonly used measure of airflow often employed to describe the capabilities of heating, ventilation, and air-conditioning systems is the "cubic feet per meter" or CFM. An increased amount of water could be extracted from air by performing airflow or CFM analysis. The result of this analysis could be used to improve the structural design of the unit, thereby resulting in an improved overall efficiency of operation.

Finally, a computerized controller could be added to the device to automatically detect the dew point and regulate the cooling-surface temperature to approximate the measured dew-point temperature of air. This approach has the advantage of reducing the power consumption and increasing the efficiency of the water harvester.

References

-

J. E. Cohen, “Population growth and Earth's human carrying capacity”, Science, 269(5222), p341, (1995).

[https://doi.org/10.1126/science.7618100]

-

P. H. Gleick, “A look at twenty-first century water resources development”, Water International, 25(1), p127-138, (2000).

[https://doi.org/10.1080/02508060008686804]

-

L. Lin, J. Chen, Z. Xu, S. Yuan, M. Cao, H. Liu, and X. Lu, “Removal of ammonia nitrogen in wastewater by microwave radiation: A pilot-scale study”, Journal of Hazardous Materials, 168(2), p862-867, (2009).

[https://doi.org/10.1016/j.jhazmat.2009.02.113]

-

A. Siddiqi, and L. D. Anadon, “The water-energy nexus in Middle East and North Africa”, Energy Policy, 39(8), p4529-4540, (2011).

[https://doi.org/10.1016/j.enpol.2011.04.023]

-

F. Trieb, and H. Mueller-Steinhagen, “Concentrating solar power for seawater desalination in the Middle East and North Africa”, Desalination, 220(1), p165-183, (2008).

[https://doi.org/10.1016/j.desal.2007.01.030]

-

M. I. Hoffert, K. Caldeira, G. Benford, D. R. Criswell, C. Green, H. Herzog, A. K. Jain, H. S. Kheshgi, K. S. Lackner, J. S. Lewis, and H. D. Lightfoot, “Advanced technology paths to global climate stability: Energy for a greenhouse planet”, Science, 298(5595), p981-987, (2002).

[https://doi.org/10.1126/science.1072357]

-

C. Charcosset, “A review of membrane processes and renewable energies for desalination”, Desalination, 245(1), p214-231, (2009).

[https://doi.org/10.1016/j.desal.2008.06.020]

-

E. Tzen, and R. Morris, “Renewable energy sources for desalination”, Solar Energy, 75(5), p375-379, (2003).

[https://doi.org/10.1016/j.solener.2003.07.010]

-

S. A. Kalogirou, “Seawater desalination using renewable energy sources”, Progress in Energy and Combustion Science, 31(3), p242-281, (2005).

[https://doi.org/10.1016/j.pecs.2005.03.001]

-

M. A. Eltawil, Z. Zhao, and L. Yuan, “A review of renewable energy technologies integrated with desalination systems”, Renewable and Sustainable Energy Reviews, 1(9), p2245-2262, (2009).

[https://doi.org/10.1016/j.rser.2009.06.011]

-

S. Solomon, G. K. Plattner, R. Knutti, and P. Friedlingstein, “Irreversible climate change due to carbon dioxide emissions”, Proceedings of the National Academy of Sciences of the USA, 106(6), p1704-1709, (2009).

[https://doi.org/10.1073/pnas.0812721106]

-

P. Woditsch, and W. Koch, “Solar grade silicon feedstock supply for PV industry”, Solar Energy Materials and Solar Cells, 72(1), p11-26, (2002).

[https://doi.org/10.1016/s0927-0248(01)00146-5]

-

H. J. Snaith, “Perovskites: The emergence of a new era of low-cost, high-efficiency solar cells”, The Journal of Physical Chemistry Letters, 4(21), p3623-3630, (2013).

[https://doi.org/10.1021/jz4020162]

-

N. G. Park, “Organometal perovskite light absorbers toward a 20% efficiency low-cost solid-state mesoscopic solar cell”, The Journal of Physical Chemistry Letters, 4(15), p2423-2429, (2013).

[https://doi.org/10.1021/jz400892a]

-

H. S. Jung, and N. G. Park, “Perovskite solar cells: From materials to devices”, Small, 11(1), p10-25, (2015).

[https://doi.org/10.1002/smll.201402767]

-

N. J. Jeon, J. H. Noh, W. S. Yang, Y. C. Kim, S. Ryu, J. Seo, and S. I. Seok, “Compositional engineering of perovskite materials for high-performance solar cells”, Nature, 517(7535), p476-480, (2015).

[https://doi.org/10.1038/nature14133]

-

K. Ummel, and D. Wheeler, Desert Power: The Economics of Solar Thermal Electricity for Europe, North Africa, and the Middle East, Center for Global Development, (2008).

[https://doi.org/10.2139/ssrn.1321842]

-

U. Deichmann, C. Meisner, S. Murray, and D. Wheeler, “The economics of renewable energy expansion in rural Sub-Saharan Africa”, Energy Policy, 39(1), p215-227, (2011).

[https://doi.org/10.1016/j.enpol.2010.09.034]

-

L. E. Bell, “Cooling, heating, generating power, and recovering waste heat with thermoelectric systems”, Science, 32(5895), p1457-1461, (2008).

[https://doi.org/10.1126/science.1158899]

-

A. W. Van Herwaarden, and P. M. Sarro, “Thermal sensors based on the Seebeck effect”, Sensors and Actuators, 10(3), p321-346, (1986).

[https://doi.org/10.1016/0250-6874(86)80053-1]

-

W. He, G. Zhang, X. Zhang, J. Ji, G. Li, and X. Zhao, “Recent development and application of thermoelectric generator and cooler”, Applied Energy, 143, p1-25, (2015).

[https://doi.org/10.1016/j.apenergy.2014.12.075]

-

A. Martinez, D. Astrain, A. Rodriguez, and P. Aranguren, “Advanced computational model for Peltier effect-based refrigerators”, Applied Thermal Engineering, 95, p339-347, (2016).

[https://doi.org/10.1016/j.applthermaleng.2015.11.021]

- H. V. Gaskill, “Method of using the peltier effect for cooling equipment”, United States Patent US 2984077, (1961).