Fatigue condition under the engine room environment and improving work accuracy

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

Familiarization of the work could reduce the difficulty of a given task, and workers can perform the work quicker. However, familiarization of the work in a long term may cause the work to be boring as it generally reduces the stress. As a result, the worker might develop an unsafe behavior through reduction of alertness. Instead of repeatedly performing the tedious work, as a common method for maintaining the accuracy at work, there can be an alternative method by inserting a break into the working schedule. The types of work in the engine room are quite diverse since there are different types of engines and machineries operating together or independently. Nevertheless, the break taken by each engineer working in engine room might be different according to operating situation. This study uses an experimental case to investigate the fatigue and its relationship to work accuracy. This experiment utilizes an equipment consist of short pipes and flange connections used in engine room. A student carries out tightening experiments to keep the flanges in place by bolts and nuts. The biological reactions were measured in an activity by heartbeat sensor and electroencephalogram head-set. The tightened bolts were made loose by torque wrench, while torque was measured simultaneously. The relations between the biological reactions and the working accuracy are investigated according to elapsed time and presented in this paper. It was concluded that working environment in the ship engine room could be improved using the optimum rest time concept, discussed for the working accuracy and safety level.

Keywords:

Work accuracy, Biological response, Optimum rest timing1. Introduction

As generally known, there exists typical unsafe behaviour which called human error at accidents [1]. For example, forgetting to plan correct work is categorized to "lapse". The wrong act which non-considering because of usually done, is categorized to "slip". The "mistakes" of knowledge based or rule based will be preventing by suitable coaching and teaching. However, "slip" and "lapse" are difficult to prevent without removing the causal element of background.

If worker have a short break in a continuous long work, the resting timing will be decided by them. For example, a worker finished part of big work, they will take a rest and they check their remaining work in resting. This resting time would be a good effect to improve the work accuracy.

The follows are based on author’s experience, and we take a short break to cool down our brain or to review the work plan. On the other hand, if we have to take a break though our brain are clear, thus our working motivation will be disturbed. It is not easy to demand the optimal rest timing.

Generally, the worker cannot decide their break timing. Usually, their manager will decide it. This situation causes a very complex problem. When manager order to take a rest for workers, however workers work motivation are high, workers motivation may change to lower after taking a rest.

At physical work situation, we well know that our heart rate is increased by work demand. A couple of researcher illustrated that relationship with heart rate changes and work strengths.

Mathiassen et al., gave participant the simple work task which pushing the two button alternator by metronome timing. Their experiments were consisting of physical work and mental task. And they found those mental tasks are good affect to participant's fatigue recovery [2].

Bellenger et al., gave the participant some athletic task. In their experiment, participant should be done 5 min cycling and running tests as an experimental task [3]. There is a gap between these experiments and the real works, participants will be done the task as experiments.

In this study, the participants were gave the nearly real work which they well known as one of engine plant maintenance work in this study. The participant might be feeling the responsibility against to result of experimental work. These experimental environment which will be reproduce the real phenomena, are big originality of our study.

In this study, we focused on result of bolt tightening work during fatigue condition of participant. The bolts tightening work is very simple, but tightening of many bolts will lead to workers fatigue and boredom. If there are some relation between with work accuracy and fatigue, to find the threshold of fatigue is useful to prevent the work accuracy reduction.

In a repeatedly bolt tightening work, we measured the biological response of participants, to clear the relation between bolt tightening accuracy and their biological response.

Participants' condition are analysed when bolt tightening failure are happened in the experiment, and we consider that detecting the occurrence of unsafe behaviour and judge occurrence.

2. Materials and Method

This study is considering for work accuracy of engineers in marine engine room situation. In this study, the participants tighten the flange bolts as an experimental work. We give participants the work load which will be change by flange setting height. The participant’s biological response is measure by following sensors.

2.1 Sensor for biological response

The participants wear the activity monitor (polar, Inc., A360) as a heart rate sensor. This wristwatch type sensor are installed a blood flow sensor at the back of display. The heart rate of participant is calculating from blood flow signals. After the experiment, these heart rate data are sent to desk top computer for recording and analysis. The display indicates the estimated heart beat per minute of the trainee in real time. This type of measurement devise will be useful for applying to worker because we can buy at store and web site.

2.2 Experimental set up

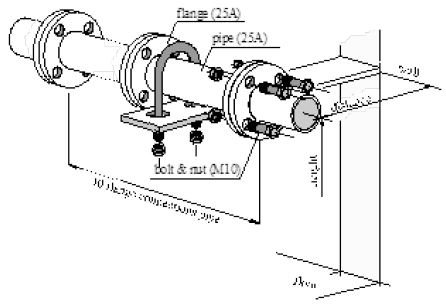

A couple of flange is combined by four bolts and nuts. The 10 sets of flange are installed as our experimental devices. The participants tighten the total 40 number of bolts and nuts in one experiment. The flange setting heights are 15 cm, 35 cm, 75 cm, 100 cm, and 125 cm from the floor. The flange setting distance from wall is fixed on 10 cm. Participant will be tighten the bolt continuously for 10 flange sets.

The rubber gaskets which are 3 mm thickness were inserted between each flange sets. The rubber gasket were compressed by tightening the bolt, thus these rubber gasket will protrude from the edge of flanges. Almost workers will check the gasket condition after the bolt tightening work. Because, it is easy to understand that bolt tightening is evenly or not.

During experiment, participant is allowed to decide on the bolt tightening order and also re-tight the tightened bolt. Figure 1 shows outline of experiment equipment.

Before the experiment, we explained the participant that it should be tightening bolt and nut evenly, to prevent the liquid leak from flange joint at real situation.

As the evaluation of work accuracy, the torque of the bolt loosen are measured when the bolts & nuts are loosen by digital torque wrench. As pair of this bolt and opposite side bolt, the counter side bolt condition will be change by loosen of one side bolt. If one side bolt becomes loose, other side bolt will be loose at the same time too. We have decide the order of loosen bolts when measure the bolt, two torques which does not affected by opposite bolt loosen, the two torque were used for evaluation of work accuracy.

2.3 Multiple regression analysis

On the assumption that the bolt tightening torque areinfluenced by work time, or participant’s physical condition, theestimation for maximal torque is given by Equation (1). A1~n.expresses the influence value of each explanation variables.

| (1) |

In estimation formula, the loosening torque is used at the criterion variable, average heart rate and elapse time of each flange are used as explanation variables. These influenced values were computed by multiple regression analysis [4].

The coefficients A1 to An are shown the influence of the heart beat which required for bolt tightening work. A multiple regression expression is composed of addition of variables. Therefore, after No.2 flange, the estimation formula has a structure that affect by previous heart beat at works.

If the sign of the coefficient A is positive, it is expected that the torque value will increase according to the heart rate required for the bolt tightening work. If the sign of the coefficient is negative, the torque value is expected to decrease. Based on the sign and value of the coefficients, quantitatively expressing the influence of participant's heart rate on the working accuracy could be expected.

3. Results of Experiment

The university students are collaborated with our experiments. The participants performed the tightening of the bolts carefully. Some students will become marine engineers at ocean going vessels in the near future. Their motivations are especially high at engineering work. However, this experimental situation is firsttime experience for them. At first, we gave them the explanation of recommend bolt tightening torque which measureable value by measurement tools for our experimental equipment. Table 1 shows eight participants profile.

3.1 Changes of heart rate during work

Setting flange height has changed to 5 kind of height in experiment. Figure 1 shows percentage of average heart rate against estimate maximal heart rate during tightening work for each flange.

The maximal heart rate [5] is defined based on the participant age. For example, participant A is 4th grade class, age is 21 years old. According to estimation formula (2), his maximal heart rate is estimated to be 192.3 beat / min.

| (2) |

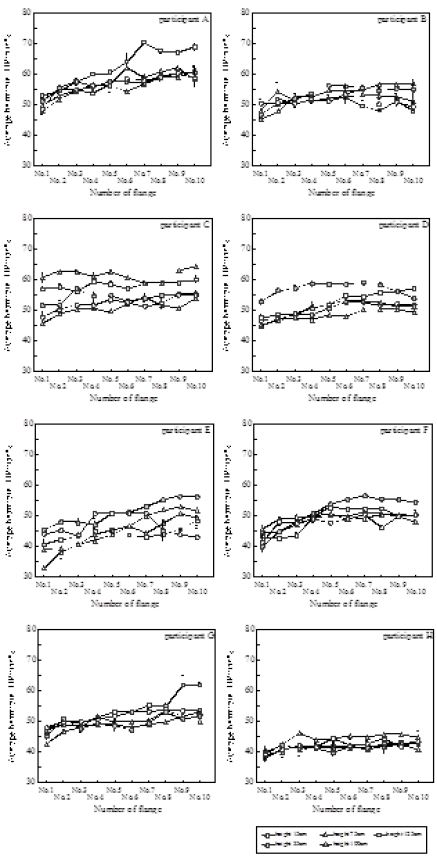

Figure 2 shows the changes of heart rate during experiment. It seems those participant heart rates were gradually increased. The lowest heart rate was observed at No.1 flange each participant and each setting height. The average heart rate was reach to 60% of maximal heart rate on participant A, C and G. And these situations were observed at setting height 125cm.

Under the prolonged physical work, heart rate reached to 60% of maximal heart rate is known as that is peak of increasing stroke value of our heart pumping. After the 60% of maximal heart rate, heart rate will gradually increase and stroke value of heart pumping will be degrease. And more over, one of the reason of increasing heart rate is lost the water contents in blood by taking the sweat is known [6].

Figure 3 shows changes of bolt loosening torque. The loosening torque of participant D, F, and H were stable torque at each setting height and each flange. However, these torque value were lower than recommended tightening torque which is around 21 [N-m] for M10 size bolt and nut in Japanese industrial standards. The loosening torque became about 70 % value of tightening torque experimentally at our experiment.

At chart of participant A, B and C, their loosening torque were bigger than other participant’s torque. They will be marine engineer near future, their motivation were especially positive for bolt tightening experiments. Sometimes, they confirmed the tightened bolt to loose or not. And then if they feel necessary, they retightened the previous bolt and nut.

3.2 Relation between tightening torque and setting height

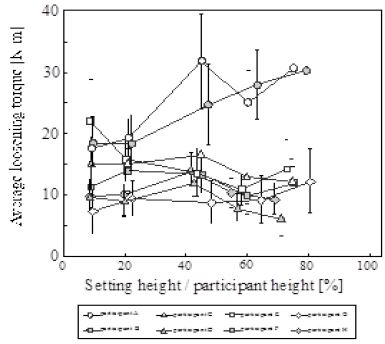

Relative flange setting height differs for each participant. It needs that evaluations of bolt tightening work accuracy were considered with these differences. Figure 4 shows average loosening torque by relative participant height.

For all participants, the standard deviation of the mean loose torque at the relative height about 20% tended to be small. The participant bended their upper body and tighten the bolt at this relative height. On the other hand, the standard deviation shows a tendency to be high at relative height 80%.

Table 2 shows correlation between number of flange and mean heart rate or loosening torque. The torque 1 is means upper bolt of flange. The torque 2 is means lower bolt of flange. There are strongly correlation between heart rate and number of flange. There was only one case which illustrated negative sign in Table 2. The lower bolt seems it gives constant tightening power by participant.

3.3 Heart beat variables

The participants' mean heart rate seems to be increase according to number of flange in Figure 2 and Table 2. During the experiment, we have measured participant heart rate and elapsed work time. Then, required heart beat were able to calculate measured heart rate and elapsed time.

The circulation blood flow value in our body will able to estimate by the one stroke of heart pumping and heart rate per minute.

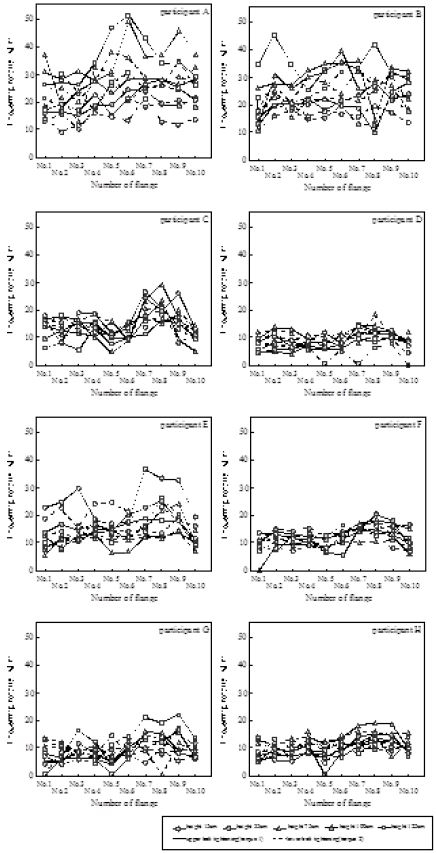

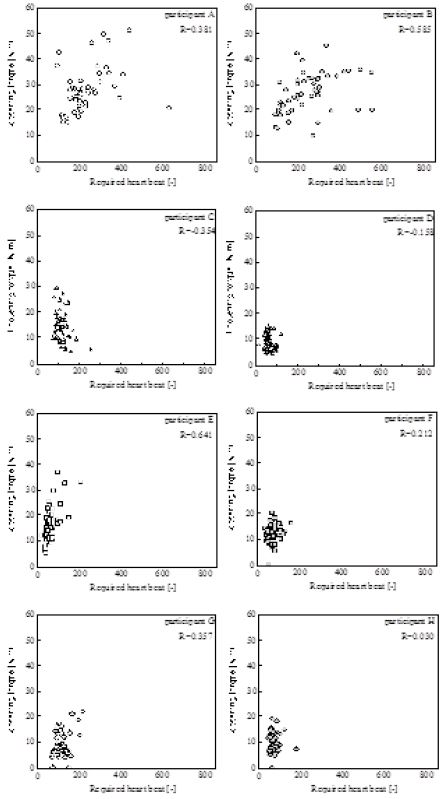

The correlation between required heart rate for work and loosening upper bolt torque were focused. In circumstances of the required heart rate increasing, the participant may be feel fatigue. It might be decreasing the work accuracy under that situation. Figure 5 shows relationship between required heart beat and loosening torque of upper bolt. The positive relationship were observed at participant B and E. And there are weak positive relationships at participant A, C and G. However, there is no correlation in participant D, F, H. As common tendency, their work time is short.

3.4 Application of multiple regressions

The explanation variables of the partial regression coefficient illustrate the effectiveness of elements. The partial regression coefficients for eight participant are given in the below Table 3 and Table 4.

The participant A, C and G whose heart rate has reached 60% of maximal heart rate in Figure 2, these coefficients are follows tendency. Their some coefficient has negative sign after No.7 flange. And these coefficients were bigger than neighbourhood’s other coefficients. The minus sign indicates a tendency for the tightening torque to decrease. These phenomena may be cause by the unstable state of the heart beat. It calls “cardiac drift” [6]. If the condition of cardiac drift continues, people feel tired or people get sweating. The sweating of the hand may reduce the power of grasping the spanner in the bolt tightening task and affect the work accuracy. These participants reported us that sweating and heated at the end of the work.

It may be suitable timing to take a break when their heart rate reaches 60% of maximal heart rate. However, degreasing of loosening torque tendency were observed at participant F’s No.5 flange. At that time, participant F’s heart rate were less than 60% of maximal heart rate. The threshold of cardiac drift phenomena seems different by person characteristic.

We found the future work that determining the threshold of heart rate which continues the work or not. In the near future, if necessary, additional sensor may be put on worker's jacket. One of the purposes will be to obtain the body temperature, or to sense the water contents on surface of worker's skin.

4. Conclusion

In analogy, since a sport athlete confirms the self-condition in daily life then, he/she can develop a good condition for a big match or a race by analysing of self-information. Similarly, a worker could be able to understand self-condition by monitoring his/her activity through measuring device, and can decide to take a rest at a best timing. In future, the worker will be able to check his condition by activity monitoring in daily life and if necessary, take a rest with optimal timing to do a safe work.

Acknowledgments

These experiments were cooperated with university students studying in marine engineering course who will become marine engineers in near future. We would like to thank them all.

This paper is extended and updated from the short version that appeared in the Proceedings of the International Symposium on Marine Engineering and Technology (ISMT 2016), held at Korea Maritime and Ocean University, Busan, Korea, November 3-4, 2016.

References

- J. Reason, “Human Error”, Cambridge University Press, (1990).

-

S. E. Mathiassen, D. M. Hallman, E. Lyskov, and S. Hygge, “Can cognitive activities during breaks in repetitive manual work accelerate recovery from fatigue? A controlled Experiment”, PLoS One, vol. 9(no. 11), p1-11, (2014).

[https://doi.org/10.1371/journal.pone.0112090]

-

C. R. Bellenger, R. L. Thomson, P. R. Howe, L. Karavirta, and J. D. Buckley, “Monitoring athletic training status using the maximal rate of heart rate increase”, Journal of Science and Medicine in Sport, vol. 19(no. 7), p590-595, (2016).

[https://doi.org/10.1016/j.jsams.2015.07.006]

- Paul G. HOTEL, Introduction to Mathematical Statics, Wiley International Edition, JOHN WILEY & SONS, Inc., p203, (1984).

- R. L. Gellish, B. R. Goslin, R. E. Olson, A. McDonald, G. D. Russi, and V. K. Moudgil, “Longitudinal modeling of the relationship between age and maximal heart rate”, Medicine and Science in Sports and Exercise, vol. 39(no. 5), p822-829, (2007).

- L. G. Ekelund, “Circulatory and respiratory adaption during prolonged exercise”, Acta Physiol Scand (Suppl), 292, p1-38, (1967).