A Study on deep learning models for transfer learning in ship spare parts classification

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

This study addresses the challenges of ship spare parts management, a critical task for ensuring maritime safety and operational efficiency. Due to the large number of components and reliance on manual processes, inventory discrepancies often occur, increasing the risk of safety incidents. To address these challenges, this research investigates transfer learning algorithms for the classification of ship spare parts. Pre-trained models, including Xception, DenseNet-201, InceptionV3, and NASNet-Large, were fine-tuned using MATLAB with the ImageNet dataset. Among the models tested, DenseNet-201 demonstrated superior performance with the lowest loss function and the highest validation accuracy. Its dense connectivity structure proved effective in minimizing misclassifications and enhancing recognition accuracy. These findings suggest that DenseNet-201 is the most suitable model for ship spare parts classification. Future work will focus on developing a real-time spare parts management system incorporating this model. The system aims to optimize operational efficiency, reduce human error, and adapt to changing requirements through automated alerts and reporting functionalities.

Keywords:

Ship spare parts management, Transfer learning, Image classification, Convolutional neural networks, DenseNet-2011. Introduction

Effective spare parts management is essential for ensuring the safety and efficiency of maritime operations. Proper inventory of spare parts on ships prevents additional risks during emergencies such as equipment failures or accidents. Without adequate management of spare parts, the safe operation of ships is compromised. The International Maritime Organization (IMO) and the International Association of Classification Societies (IACS) have established various regulations concerning ship safety and operation [1][2]. In particular, the International Convention for the Safety of Life at Sea (SOLAS) and ISM 2008 Amend / Part A / 10 specify guidelines for ensuring the safe operation of ships, including mandatory management of required spare parts [3]. Ships are therefore obligated to manage spare parts in compliance with these guidelines.

Ships are equipped with a variety of mechanical and electrical systems, each requiring numerous spare parts for maintenance. Managing these parts, especially the mandatory spare parts specified by regulations, is a complex and labor-intensive task. Currently, crew members rely heavily on manual processes to oversee spare parts inventory, spending approximately 20% of their working hours on such tasks [4]. This involves comparing inventory items with blueprints and part numbers, which are not only inefficient but also prone to human error. For instance, discrepancies between actual and recorded inventory levels can prevent timely replacement of parts during emergencies, potentially leading to significant accidents [5].

There is a need for a maritime spare parts management method that reduces human involvement. This study proposes a model using transfer learning to improve operational efficiency and stability in ship operations.

In the logistics industry, various classification technologies such as barcodes, RFID, and QR codes are already widely used for inventory management [6]-[8]. However, these systems face challenges when applied directly to maritime environments. Assigning individual codes to each component increases the work-load of crew members, and the diverse supply chain characteristics of ship parts make it difficult to standardize product numbers. Furthermore, damage to barcodes or other identifiers can hinder the identification of spare parts [9].

This study focuses on exploring classification methods for ship spare parts using transfer learning models. The goal is to develop an efficient classification model that improves the accuracy of spare parts recognition and categorization while utilizing a minimal dataset [10]. Effective classification models typically require large datasets for training, which poses limitations in terms of resources. To address this issue, the study leverages pretrained models from other industries to develop a classification model for ship spare parts. Transfer learning accelerates the training process, reduces the amount of data needed for training, and applies pre-learned knowledge to new tasks [11]. Models trained on large-scale datasets like ImageNet, which contains millions of labeled high-resolution images, can recognize diverse image features and patterns [12].

Therefore, this research aims to classify spare parts using transfer learning and optimize a model that can be applied to develop a spare parts management system tailored to maritime environments [13].

2. Current Status and Regulations for Ship Spare Parts Management

Ships are equipped with a wide range of machinery essential for maritime operations and environmental conditions. Maintaining this machinery is critical to ensuring the safe and reliable operation of ships. On average, a ship contains more than 200 types of machinery, and considering the associated spare parts and consumables, approximately 62,000 spare parts are required to support operations.

While ships are obligated to maintain and manage spare parts as stipulated by regulations, challenges arise from the diversity of manufacturers supplying these parts and the lack of standardized supply chains for individual vessels. Currently, the management of spare parts is primarily carried out by crew members responsible for each piece of equipment. Due to the large volume of spare parts and the need to manually compare them with schematics, the management process is inefficient. Human errors in this process can result in discrepancies or omissions in inventory, leading to the risk of severe maritime accidents in emergency situations [14].

To mitigate these issues, the International Maritime Organization (IMO) enforces the management of legally mandated spare parts through the International Convention for the Safety of Life at Sea (SOLAS). Legally required spare parts refer to essential components and equipment that must be managed according to regulations to ensure the safe operation of vessels. These requirements, including the types and quantities of spare parts, vary based on factors such as the type of vessel, its size, and its operational area, and are subject to periodic review and updates [15].

The maintenance of seaworthiness and operational safety is stipulated under Article 26 of the Ship Safety Act, while Chapter 12 of the Standards for Ship Machinery outlines the requirements for spare parts, tools, and equipment. Table 1 provides examples of mandatory spare parts specified in the regulations, particularly for propulsion systems, such as main engines.

Establishing an automated spare parts management system is essential for enhancing operational efficiency and safety. Such systems should include features for automated inventory tracking, spare parts ordering and supply chain management, expiration tracking, automated storage, usage history tracking, and spare parts analysis and reporting. This study focuses on the identification process for spare parts, which is foundational for effective ship spare parts management [16]. Advanced technologies, such as AI-based identification systems, offer the potential to overcome the limitations of traditional methods and significantly improve the efficiency and reliability of spare parts management [17]-[19].

3. Proposed Model for Ship Spare Parts Management Using Transfer Learning

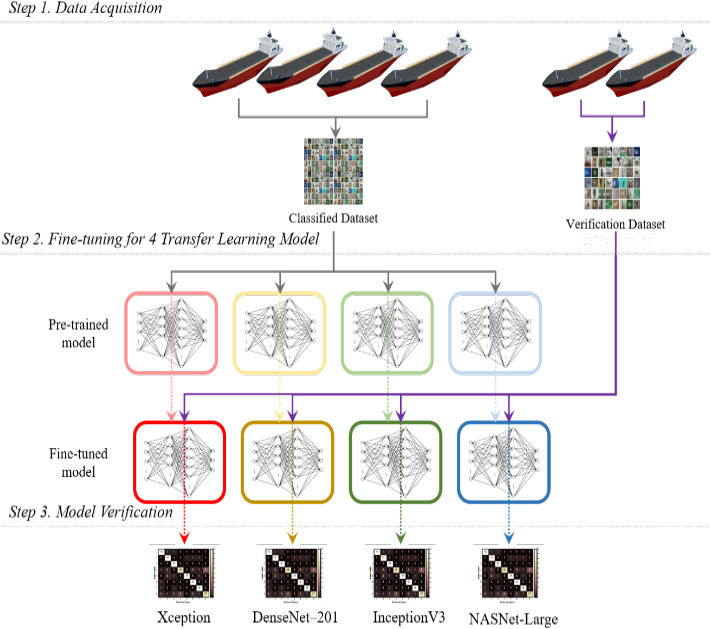

This study aims to classify spare parts for ship equipment by training four models—Xception, DenseNet-201, InceptionV3, and NASNet-Large—chosen for their accuracy[20]-[24]. Each model underwent training, and the results are compared. Following the training, the models were validated with a separate dataset to determine recognition accuracy and identify the most suitable model. Figure 1 illustrates the workflow for this study on spare parts classification models.

3.1 Data Preparation and Processing

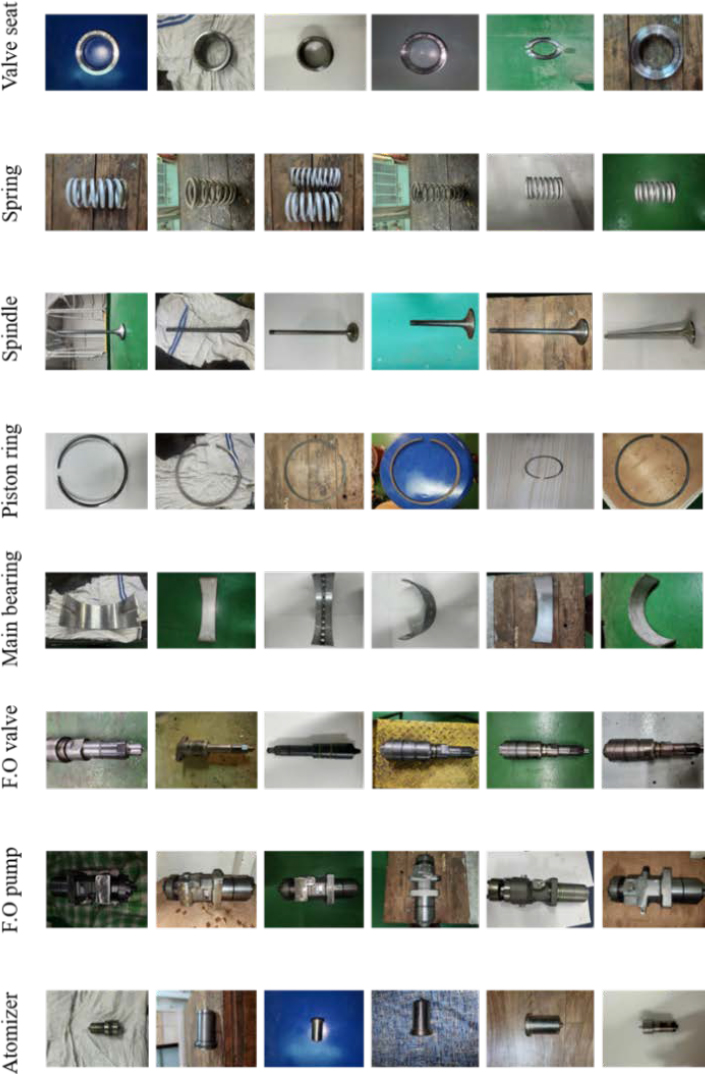

To train the prediction model using transfer learning, a dataset containing actual ship machinery spare parts is utilized. The study focused on essential spare parts for the HIMSEN engine, a four-stroke generator manufactured by Hyundai Heavy Industries with the highest market share. Table 2 shows the eight types of spare parts selected for the study and the legally required quantities.

The dataset includes 500 images for each of the eight spare parts (a total of 4,000 images) for training and validation. An additional 50 images per part (totaling 400 images) are reserved as an independent validation dataset. For training and validation, the dataset was split into a 7:3 ratio, comprising 350 training images and 150 validation images per part, with the independent dataset uses exclusively for testing.

The dataset is processed to resize images to fit the requirements of pre-trained models, which use sizes such as 128×128 pixels for training. This resolution is chosen to balance training time and classification accuracy, as excessively small images might cause errors or overfitting during training. Figure 2 presents an example of the dataset uses in this study.

3.2 Neural Network Training for Ship Spare Parts Management

This subsection outlines the primary characteristics of the neural network models used in this study, including their input size, network type, number of layers, model size, number of classes, and parameter count. These factors are carefully considered to ensure the selection of models capable of accurately classifying ship spare parts.

DenseNet-201, Xception, InceptionV3, and NASNet-Large are employed as pre-trained models for transfer learning. Each model features distinct architectural advantages: DenseNet-201's densely connected layers enhance feature propagation and reduce information loss; Xception optimizes the depthwise separable convolution for efficient feature extraction; InceptionV3 balances depth and computational efficiency; and NASNet-Large, designed through neural architecture search, achieves state-of-the-art performance with a larger parameter set. The key characteristics of these models appear in Table 3.

These models are selected based on their compatibility with the dataset’s characteristics and the computational resources available. DenseNet-201, in particular, stands out for its efficient use of parameters, making it suitable for tasks with smaller datasets. The evaluation of these models provides insights into their applicability for real-world ship spare parts classification tasks.

The models are trained using parameters listed in Table 4. The Adam optimizer is employed to adjust weights during training, with an initial learning rate of 0.0001 and a learning rate drop factor of 0.1 every 10 epochs. The batch size is set to 4, and early stopping is applied with a patience of 15 epochs to prevent overfitting.

The training process is conducted using MATLAB's Deep Network Designer, leveraging the computational capabilities of a GPU to accelerate the learning process. These configurations ensure efficient training and testing of the models.

4. Model Training and Results

This section details the training process and results obtains from applying transfer learning models to the classification of ship spare parts, including the visual representation of accuracy and loss.

4.1 Training Process

The classification models use in this study—Xception, DenseNet-201, InceptionV3, and NASNet-Large—aree trained using a dataset consisting of 4,000 images. Among these, 3,500 images are allocated for training, while the remaining 500 are used for validation. The training process is conducted over 50 epochs, with performance metrics including training accuracy, validation accuracy, loss function values, and misclassification rates being monitored to evaluate each model's effectiveness.

Key training parameters are configured as follows: the Adam optimizer is employed with an initial learning rate of 0.0001, a learning rate drop factor of 0.1, and a drop period of 10 epochs. The batch size is set to 4, and early stopping was applied with a patience threshold of 15 epochs to prevent overfitting. The training is executed in a GPU-accelerated environment to reduce computational time and ensure efficient learning.

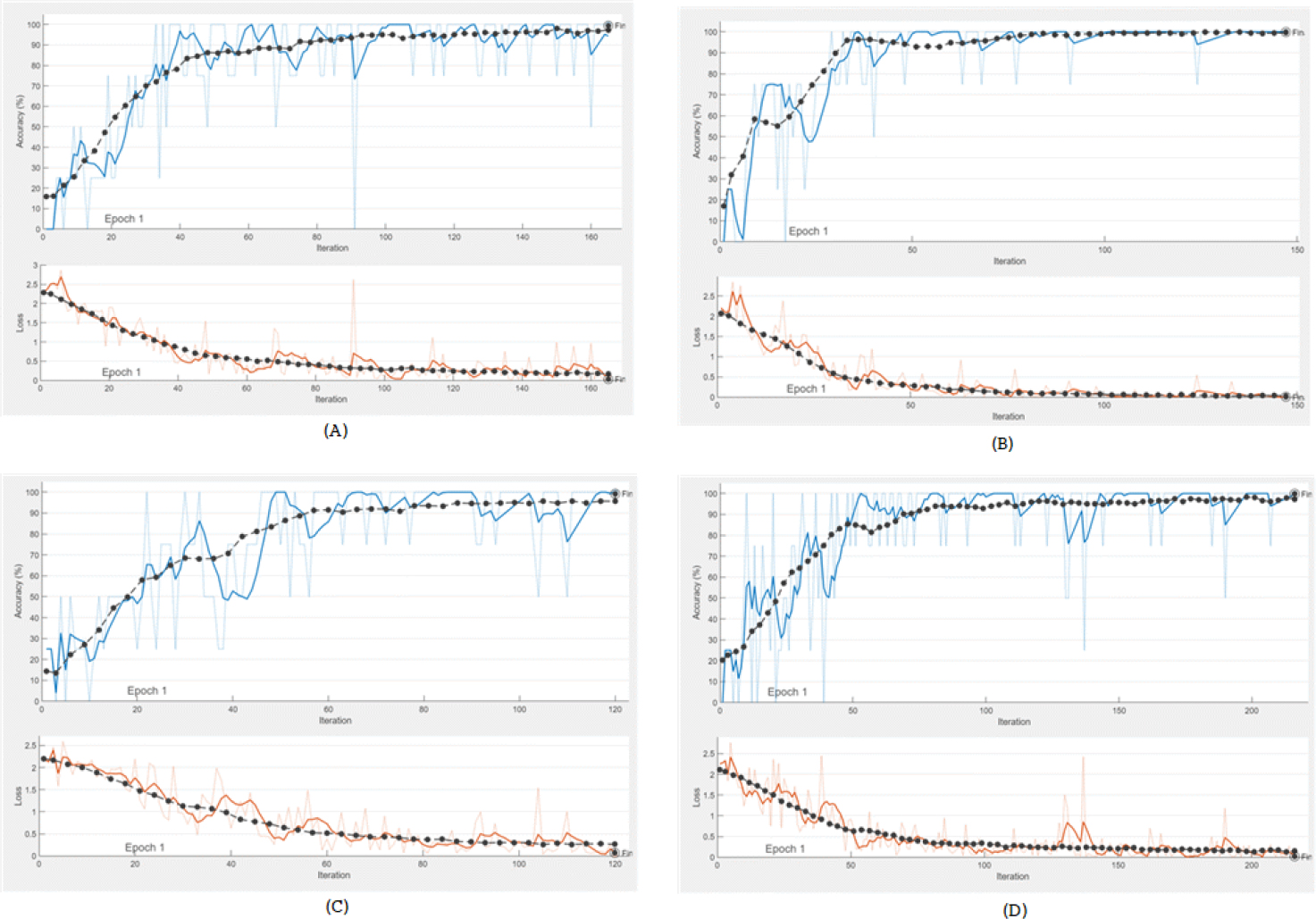

Figure 3 illustrates the training and validation accuracy, as well as the loss values, for each model over 50 epochs. DenseNet-201 demonstrated the most stable convergence and the lowest loss value throughout the training process, indicating superior learning efficiency [25].

4.2 Training Results

The training outcomes for the four models are summarized in Table 5. DenseNet-201 achieved the highest validation accuracy and the lowest loss value, demonstrating superior performance compared to the other models.

Among the models evaluated, DenseNet-201 demonstrated the best overall performance, achieving a validation accuracy of 98.50% and a loss value of 0.0113. Its densely connected layers effectively minimized information loss during training, enhancing learning efficiency. Additionally, DenseNet-201 exhibited the lowest misclassification count (6), further validating its reliability in the classification of ship spare parts.

In comparison, Xception and InceptionV3 delivered competitive performance but are slightly less accurate than DenseNet-201. The validation accuracies for Xception and InceptionV3 were 96.80% and 97.20%, respectively, with slightly higher loss values and misclassification counts.

NASNet-Large, despite its complex architecture and strong performance in other applications, showes the lowest validation accuracy and the highest loss value in this study. This result can be attributed to the relatively small size of the dataset and the high computational complexity of NASNet-Large, which may require larger datasets to fully utilize its capabilities.

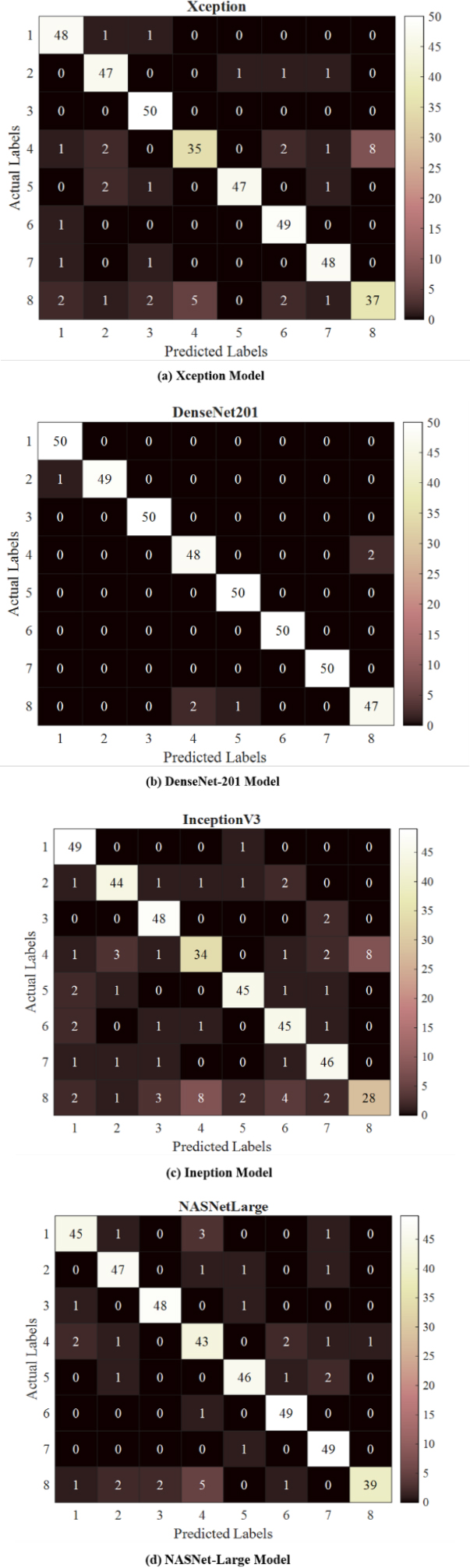

After training is completed, the models are evaluated using an independent dataset of 400 images that are not used during training. The evaluation results are visualized using confusion matrices, as shown in Figure 4. A confusion matrix is a tool used to assess the performance of a classification model by presenting the relationship between actual labels and predicted labels in a tabular format. It allows us to analyse how accurately the model classifies each category and identifies the misclassified samples. The evaluation results are further analysed using accuracy metrics and misclassification counts for comparative analysis[26]. These findings are illustrated in Figure 4.

DenseNet-201 achieves the lowest misclassification rates across the categories, reinforcing its suitability as the optimal model for this application.

4.3 Analysis and Discussion

The results confirm that DenseNet-201 is the most effective model for classifying ship spare parts. Its dense connectivity architecture facilitates the efficient propagation of gradients and information, resulting in higher accuracy and lower error rates compared to other models. The model's ability to achieve superior performance with minimal misclassifications underscores its applicability in practical maritime environments.

The evaluation also highlights the limitations of NASNet-Large, which, due to its complexity, performed sub optimally in this study. This suggests that the choice of model should consider the dataset size and computational constraints inherent to the application domain.

In summary, DenseNet-201 outperforms the other models and is identified as the most suitable model for ship spare parts classification. These findings will serve as the foundation for developing an automated spare parts management system, contributing to improved operational efficiency and safety in maritime applications.

5. Conclusion

This study aimed to enhance the management of ship spare parts by developing an efficient classification model using transfer learning and convolutional neural networks (CNN). The research investigated four advanced pre-trained models—Xception, DenseNet-201, InceptionV3, and NASNet-Large—to evaluate their suitability for ship spare parts classification. The experimental results demonstrate that DenseNet-201 exhibited superior performance in terms of accuracy, loss value, and misclassification rate compared to the other models.

The DenseNet-201 model achieved the highest validation accuracy (98.50%) and the lowest loss value (0.0113). Its dense connectivity architecture minimized information loss during training and facilitated the propagation of features and gradients, resulting in effective learning. Furthermore, DenseNet-201 demonstrated a misclassification count of only six, indicating its high reliability in distinguishing between different categories of ship spare parts. These results confirm that DenseNet-201 is the most suitable model for practical applications in the maritime industry.

In contrast, models such as Xception, InceptionV3, and NASNet-Large, while competitive, fell short of DenseNet-201's performance. NASNet-Large, in particular, exhibited suboptimal results, likely due to its higher computational complexity and reliance on larger datasets, which were not available for this study. This finding underscores the importance of selecting models tailored to the specific constraints and characteristics of the dataset and application domain.

Future research will focus on integrating DenseNet-201 into a real-time spare parts management system, expanding the dataset for improved model robustness, and incorporating advanced features such as predictive maintenance and automated alerts. This study establishes a foundation for leveraging machine learning to enhance efficiency and safety in ship spare parts management.

Acknowledgments

This work was supported by the Korea Maritime & Ocean University Research Fund in 2021.

Author Contributions

Conceptualization, Y.-C. Lee and T. Jeon; Methodology, Y.-C. Lee; Software, Y.-C. Lee; Validation, Y.-C. Lee and T. Jeon; Formal Analysis, M. Kim; Investigation, H. J. Jang; Resources, H. J. Jang; Data Curation, H. J. Jang; Writing—Original Draft Preparation, M. Kim; Writing—Review & Editing, T. Jeon; Visualization, Y.-C. Lee; Supervision, T. Jeon; Funding Acquisition, Y.-C. Lee.

References

-

J. Harrison, “International maritime organization,” International Journal of Marine & Coastal Law, vol. 24, p. 727, 2009.

[https://doi.org/10.1163/092735209X12499043518340]

-

R. Nersesian and S. Mahmood, “International association of classification societies,” Handbook of Transnational Economic Governance Regimes, pp. 765-774, 2010.

[https://doi.org/10.1163/ej.9789004163300.i-1081.675]

- International Maritime Organization (IMO). (1974/2020). International Convention for the Safety of Life at Sea (SOLAS), 1974, as amended. Chapter IX (Management for the Safe Operation of Ships) – ISM Code, Section 10 (Maintenance of the Ship and Equipment). London: IMO.

- N. Al-Shammari and J. Oh, “Effects of human error on marine safety: Case study,” Journal of Engineering Research and Applications (IJERA), vol. 8, pp. 11-19, 2018.

- H. J. Jang, Development of a Classification Model for Ship Spare Parts Management based on Semi-Supervised Generative Adversarial Networks, National Korea Maritime & Ocean University, 2024.

-

S. Alyahya, Q. Wang, and N. Bennett, “Application and integration of an RFID-enabled warehousing management system–a feasibility study,” Journal of Industrial Information Integration, vol. 4, pp. 15-25, 2016.

[https://doi.org/10.1016/j.jii.2016.08.001]

-

R. Bose, H. Mondal, I. Sarkar, and S. Roy, “Design of smart inventory management system for construction sector based on IoT and cloud computing,” E-Prime: Advances in Electrical Engineering, Electronics and Energy, vol. 2, 100051, 2022.

[https://doi.org/10.1016/j.prime.2022.100051]

-

S. Nemeshaev and A. Fatkullina, “Predictive analytics of the state of computer devices in the inventory system,” Procedia Computer Science, vol. 190, pp. 647-650, 2021.

[https://doi.org/10.1016/j.procs.2021.06.103]

-

H. Kim, S. Na, and W. Ha, “A case study of marine accident investigation and analysis with focus on human error,” Journal of the Ergonomics Society of Korea, vol. 30, pp. 137-150, 2011 (in Korean).

[https://doi.org/10.5143/JESK.2011.30.1.137]

- K.B. Obaid, S. Zeebaree, and O.M. Ahmed, “Deep learning models based on image classification: A review,” International Journal of Science and Business, vol. 4, pp. 75-81, 2020.

-

T. Berghout, L. Mouss, T. Bentrcia, E. Elbouchikhi, and M. Benbouzid, “A deep supervised learning approach for condition-based maintenance of naval propulsion systems,” Ocean Engineering, vol. 221, 2021.

[https://doi.org/10.1016/j.oceaneng.2020.108525]

- A. Krizhevsky, I. Sutskever, and G.E. Hinton, “Imagenet classification with deep convolutional neural networks,” Advances in Neural Information Processing Systems, vol. 25, 2012.

-

A. Abade, P.A. Ferreira, and F. de Barros Vidal, “Plant diseases recognition on images using convolutional neural networks: A systematic review,” Computers and Electronics in Agriculture, vol. 185, 2021.

[https://doi.org/10.1016/j.compag.2021.106125]

-

C.M. Lee, H.J. Jang, and B.G. Jung, “Development of an automated spare-part management device for ship controlled by raspberry-Pi microcomputer based on image-processing & transfer-learning,” Journal of Marine Science and Engineering, vol. 11, no. 5, 2023.

[https://doi.org/10.3390/jmse11051015]

-

R. Kian, T. Bektaş, and D. Ouelhadj, “Optimal spare parts management for vessel maintenance scheduling,” Annals of Operations Research, vol. 272, pp. 323-353, 2019.

[https://doi.org/10.1007/s10479-018-2907-y]

-

M. Shaha and M. Pawar, “Transfer learning for image classification,” pp. 656-660, 2018.

[https://doi.org/10.1109/ICECA.2018.8474802]

-

R. Chauhan, K.K. Ghanshala, and R.C. Joshi, “Convolutional neural network (CNN) for image detection and recognition,” 2018 First International Conference on Secure Cyber Computing and Communication (ICSCCC), Jalandhar, India, pp. 278-282, 2018.

[https://doi.org/10.1109/ICSCCC.2018.8703316]

-

M.A. Hossain and M.S.A. Sajib, “Classification of image using convolutional neural network (CNN),” Global Journal of Computer Science and Technology, vol. 19, no. 2, pp. 13-14, 2019.

[https://doi.org/10.34257/GJCSTDVOL19IS2PG13]

- S.K. Jayapalan and S. Anuar, “Transfer learning based network performance comparison of the pre-trained deep neural networks using MATLAB,” Open International Journal of Informatics, vol. 10, pp. 27-40, 2022.

-

F. Chollet, “Xception: Deep learning with depth wise separable convolutions,” Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, pp. 1251-1258, 2017.

[https://doi.org/10.1109/CVPR.2017.195]

-

S. Wang and Y. Zhang, “DenseNet-201-based deep neural network with composite learning factor and precomputation for multiple sclerosis classification,” ACM Transactions on Multimedia Computing, Communications, and Applications (TOMM), vol. 16, pp. 1-19, 2020.

[https://doi.org/10.1145/3341095]

-

N. Dong, L. Zhao, C. Wu, and J. Chang, “Inception v3 based cervical cell classification combined with artificially extracted features,” Applied Soft Computing, vol. 93, 2020.

[https://doi.org/10.1016/j.asoc.2020.106311]

-

M. Mehmood, N. Alshammari, S.A. Alanazi, A. Basharat, F. Ahmad, and M. Sajjad, “Improved colorization and classification of intracranial tumor expanse in MRI images via hybrid scheme of Pix2Pix-cGANs and NASNet-large,” Journal of King Saud University-Computer and Information Sciences, vol. 34, pp. 4358-4374, 2022.

[https://doi.org/10.1016/j.jksuci.2022.05.015]

-

D.F. Cook, C.T. Ragsdale, and R.L. Major, “Combining a neural network with a genetic algorithm for process parameter optimization,” Engineering Applications of Artificial Intelligence, vol. 13, pp. 391-396, 2000.

[https://doi.org/10.1016/S0952-1976(00)00021-X]

-

C. Wen, X. Yang, K. Zhang, and J. Zhang, “Improved loss function for image classification,” Computational Intelligence and Neuroscience, vol. 2021, 6660961, 2021.

[https://doi.org/10.1155/2021/6660961]

-

X. Deng, Q. Liu, Y. Deng, and S. Mahadevan, “An improved method to construct basic probability assignment based on the confusion matrix for classification problem,” Information Sciences, vol. 340, pp. 250-261, 2016.

[https://doi.org/10.1016/j.ins.2016.01.033]