Implementation of knowledge management to support design tasks of large-scale complex system

Copyright © The Korean Society of Marine Engineering

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/3.0), which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Abstract

A large-scale complex system (LSCS) is an engineering product comprising of numerous components and interconnected subsystems. The LSCS is required to change its design or develop new systems to introduce new technologies. Additionally, the LSCS must be developed to reflect changes in regulations and external environmental factors. In this study, a knowledge management system was suggested to technically support design tasks. The proposed system provides functions to search for informally created tacit knowledge during the LSCS design stage and to connect the relationship between tacit knowledge and design results. The proposed system is expected to improve accessibility to tacit knowledge and promote the understanding of design results generated across various engineering fields, thereby facilitating prompt and accurate progress in design work. When designing a new LSCS system, trial and error in design can be reduced, and expeditious technical training for new design personnel can be supported by securing tacit knowledge derived from the previous system development process. The proposed system is expected significantly help secure, maintain, and manage organization's technical capabilities.

Keywords:

Large-scale complex system, System design, Tacit knowledge, Knowledge transfer, Knowledge management1. Introduction

A large-scale complex system (LSCS) is an engineering product comprising of numerous components and interconnected subsystems. LSCSs appear in various engineering fields, such as shipbuilding, energy, power systems, manufacturing, aerospace, civil and construction engineering, and transportation [1]. The LSCS is required to change its design or develop new systems to introduce new technologies. The LSCS must be developed to introduce the latest technology and reflect changes in regulations and external environmental factors. For example, the shipbuilding industry is required to develop new ships that are different from existing ones, such as larger ships, to reflect the increased load due to the increase in global logistics movement, and carbon-reducing ships that seriously consider environmental issues, such as carbon neutrality. In the nuclear power industry, the development trend is changing from existing large nuclear power plants to small nuclear power plants and even micro nuclear power plants to secure safety and economic efficiency, export competitiveness, and use as a multi-purpose energy generation source.

An LSCS system has the characteristics of a long construction period, high construction costs, and long-term operation after construction. In the design stage of the construction of a new LSCS, the applicability of newly established laws and the latest technologies are considered, and the maintenance of the facility for long-term operation and securing parts inventory are considered simultaneously. In addition, because it reflects improvements compared with the existing design and seeks to improve performance and safety, the design work of the LSCS can be estimated by researching and developing a new facility for each design, rather than simply copying the previous product. Therefore, the new construction of the LSCS must start from the design process anew, even if its purpose, function, and physical shape are quite similar to those of the reference facility, unlike products that are quickly mass-produced according to drawings with the same specifications.

Because each design is different, LSCS design work frequently requires the design-related knowledge and problem-solving skills of an experienced professional, even though the work is performed according to procedures, formats, and documents established by the organization. If the main design tasks are overly dependent on a small number of experienced people, the design work may not proceed appropriately. This delays the design process and makes it difficult to ensure design quality. In addition, since the transfer of informal and unformed knowledge that only a few experienced people have is done individually, there is a problem that it is difficult for the organization to transfer knowledge and maintain technical skills.

Therefore, in this study, a knowledge management system was developed to support design tasks by systematically managing unformatted information.

2. Knowledge Management for Design Task

2.1 Knowledge Management

Knowledge management is a method that benefits from the knowledge that resides in an organization by using it to accomplish the organization’s mission [2]. As it has been known that applying knowledge management can facilitate sharing of work methods and processes, promote organizational activation and cohesion, provide knowledge for decision-making, increase productivity, and contribute to customer satisfaction, many studies have been conducted to apply it in various industries [3]-[5].

Knowledge management uses members’ knowledge, abilities, skills, and experiences in a systematic and organized manner to improve efficiency, ensure competitive advantage, achieve goals, and spur innovation [6]. In knowledge management, knowledge refers to combining information with individual, group, and organizational experiences, skills, and judgment, and includes transitioning from understanding problems to understanding patterns that can derive solutions [6]. Knowledge management in organizations is based on an understanding of knowledge creation and knowledge transfer [2]. Knowledge transfer generally refers to knowledge sharing that focuses on departments, organizations or groups rather than on individuals [7].

Various forms of knowledge are available. Knowledge can be divided into explicit and tacit knowledge. Explicit knowledge is codified and transmittable in formal, systematic language, while tacit knowledge is personal, context-specific, and difficult to codify [8]. Tacit knowledge is personal in origin, job specific, related to context, difficult to fully articulate, and poorly documented, but highly operational in the minds of the possessor [9]. The characteristics of tacit and explicit knowledge are presented in Table 1 [2][6].

Knowledge management is the systematic approach of organizations to manipulate and take advantage of both explicit and tacit knowledge, which in turn leads to the creation of new knowledge [6]. Explicit knowledge utilization is commonly achieved through formally issued documents, work manuals, and regular OJT (on the job training). However, the utilization of tacit knowledge tends to depend largely on the capabilities of members. The benefits of applying the knowledge management concept are clear, however, the key is to organize the tacit knowledge that exists at the individual level to be revealed at the organizational level. To achieve this, it is necessary to understand the characteristics of the work to which knowledge management should be applied.

2.2 Tacit Knowledge obtained from Design tasks for Large-scale Complex System

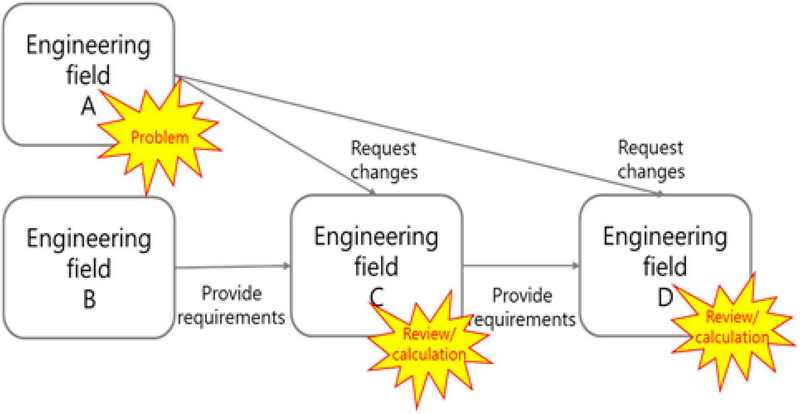

According to the characteristics of the LSCS, engineering technologies from various fields, such as mechanical, structural, material, fluid, measurement and control, and human engineering, are combined to develop the LSCS. Information generated in one engineering field can serve as a technical basis for design tasks or as a result of securing design validity in another engineering field. This can also be a requirement or limitation that leads to design changes. An example of the interconnections between various engineering fields that occur during the design process is shown in Figure 1.

In the nuclear facility design process, field (A) analyzes the performance or safety of the system, collects all design results derived from other fields, and checks whether safety and performance requirements are satisfied. If any dissatisfaction or problem occurs at this time, the analysis field (A) requests the relevant engineering fields (C and D) to re-examine and recalculate to resolve it. For example, the mechanical design field (C) is required to review structural integrity, and the fluid design field (D) is required to re-examine the flow rate calculation. At this time, the mechanical design field (C) must satisfy the requirements and restrictions for the material properties provided by the material design field (B) during the review and design change process, and the fluid design field(D) must also satisfy the requirements and restrictions for equipment integrity provided by the mechanical design field (C) during the calculation and design change process to solve the problem raised by the analysis field (A). As in the example explained above, changes in one engineering field require a comprehensive review to determine if there are any effects on other fields; therefore, they must proceed while organically understanding each other's work.

Because of the characteristics of LSCS design work, as mentioned in the example, various related engineering fields repeatedly go through the process of discussing and solving problems, determining the direction of tasks, sharing task results, and discussing design changes during the LSCS design work process. A considerable number of diverse technical opinions are derived through discussions to recognize and resolve dissatisfaction. The information generated through this process can be defined as design-related tacit knowledge. Most design-related tacit knowledge has not been documented formally. However, they are highly effective in increasing the understanding of the task and gaining insight. If this knowledge is easily accessible to designers, it will increase their understanding of design tasks across fields, which will, in turn, reduce design errors. In addition, if this knowledge is systematically linked to design results, well-preserved, and accessible to designers, they can appropriately refer to the relevant materials as technical basis information on directions for problem-solving and decisions regarding dissatisfaction issues that occurred in the past. Designers can consult knowledge of similar cases that have occurred in the past to increase their understanding and gain insight into resolving current dissatisfaction.

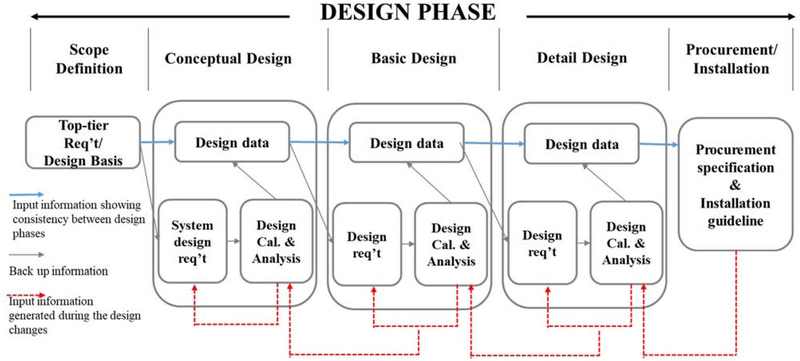

The design work of the LSCS, in which multiple engineering fields are simultaneously involved and organically linked, can have a significant impact on the design process and completion level, even with a small change, depending on the depth of the connection between fields. Therefore, the design status is defined according to the design level, and the design information is confirmed and documented at the end-point of the design status, which called the baseline. The design of LSCS is categorized into three statuses: concept design, basic design, detailed design statuses. The main tasks for each status are as shown in the Table 2.

If dissatisfaction is not resolved through the process shown in Figure 1, the upper-level design requirements must be changed. Subsequently, the designers return to the previous design stage. When top-level requirements such as relevant laws, regulatory guidelines, technical standards, user requirements are changed, designers must incorporate these changes in the middle of the design stage. If the current design change cannot absorb the changes, designers should return to the previous design stage for upper-level design requirement changes, as shown in Figure 2.

In a situation where the design requirements of the previous stage need to be changed and a return to the previous design stage is required, the design results that have been performed thus far must be overturned, and the design tasks have already been conducted again according to the changed requirements. At this time, more diverse engineering fields may need to be linked, unlike in the case of simple problem-solving. This has a significant impact on design quality in terms of ensuring design consistency, and causes a huge loss of time and cost from the perspective of the entire construction process point of view. Unexpected dissatisfaction can occur at any time during long and complex design process, and system designers must be able to deal with it. If designers can refer to the knowledge derived from past cases, it can be of great help in determining the response direction and response plan to minimize technical quality deterioration owing to design changes and minimize the time and cost damage in the process.

2.3 Necessity of Application of Knowledge Management to Design Tasks for Large-scale Complex System

Among the knowledge generated in the design tasks described in Section 2.2, explicit knowledge, mentioned in this paper as design information and results, is formalized according to the documentation procedures and work guidelines systematically established by the organization. To confirm the consistency of the design information, activities for improving the quality of design and operation, such as document management, technology management, process management, quality management, and configuration management, were carried out based on documented design information.

However, a significant amount of the information generated during design changes and design phase repetitions is in the form of tacit knowledge. They are not documented but are solely dependent on the designers’ individual memories and experiences. Tacit knowledge can significantly enhance the understanding of the current situation. This knowledge has the potential to provide insight that supports design tasks by providing opportunities to refer to past cases when setting a way of working on the next status or the next project.

Tacit knowledge tends to be transferred verbally from person to person because there is no systematic procedure for knowledge transfer. Knowledge related to problems that do not occur frequently does not need to be frequently transferred. If knowledge is not transferred, it is lost regardless of its importance. Knowledge related to long-term and complex tasks may not be transferred accurately or may be transferred insufficiently. This represents a significant loss in terms of maintaining technical knowledge. In addition, if tacit knowledge transfer relies on the knowledge and experience of an individual, the dependence on a small number of experts increases. This causes technological extinction owing to the aging of professional members and failure to transfer knowledge to young members, which can be a great loss in terms of maintaining the technical capabilities of an organization. Therefore, it is necessary to apply the concept of knowledge management to tacit knowledge created in the design stage, which is the first step in determining the quality of the LSCS during the LSCS construction process, and is time consuming and costly.

3. Application of Knowledge Management for Design Tasks

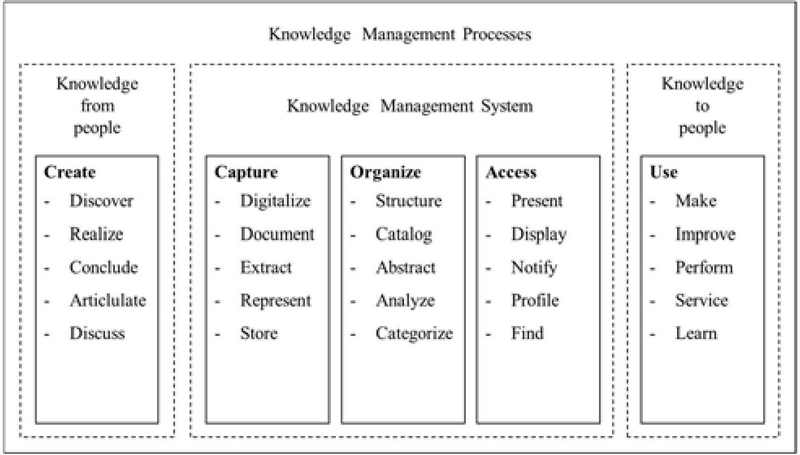

Knowledge management refers to supporting the transfer of knowledge from one person to another based on systematic procedures. The processes that a knowledge management system must undergo for the successful transfer of tacit knowledge are shown in Figure 3.

Knowledge creation is the first stage of the knowledge management process. Individuals initially generate knowledge. From a knowledge management perspective, it is important to recognize useful and valuable information. It is a form of discovery, realization, articulation, discussion, and conclusion. Extracted knowledge that is estimated to be valuable must be captured. Knowledge can easily be lost and must be captured in methods such as digitalization and documentation. Knowledge can have the phase of being valuable and usable only when it is structured and classified according to its content and use. Organized knowledge must be accessed in a way that meets the needs of users. It must be output appropriately for the search conditions, such as the content or situation that users want, so that it can be delivered to users in a usable form. When knowledge is delivered to users, they learn, apply, and transform it and gain insight to create new knowledge. The newly created knowledge is captured in the physical form mentioned above and appropriately delivered to users through a structured and categorized process. By conducting knowledge management processes repeatedly, users can receive support for their work by referencing more knowledge over time.

When knowledge management processes are applied to the tacit knowledge generated in the design work, they can be refined as follows: In this study, a knowledge management system that considers the tacit knowledge created from the design tasks of the LSCS construction process was developed.

- ● Create: Tactic knowledge created through design statuses typically encompasses a form of discussion regarding dissatisfaction, analysis direction, analysis progress, analysis results, calculation progress and calculation results.

- ● Capture: The created knowledge is captured, such as work proceedings or minutes, presentation materials, informal documents containing analysis or calculation results, and email correspondence files.

- ● Organize: When searching for explicit knowledge, tacit knowledge can be simultaneously accessed as the technical basis for inducing explicit knowledge by connecting captured tacit knowledge with officially documented explicit knowledge.

- ● Use: Users can check whether tacit knowledge is connected to explicit knowledge according to their search conditions. By simultaneously confirming tacit knowledge, users can verify the technical requirements or background conditions that are affected as the reasons for generating explicit knowledge. Users can be supported to help them understand explicit knowledge and produce new tacit knowledge, such as gaining insight.

In this study, a knowledge management system was developed that applies the concept of knowledge management to tacit knowledge created from the design tasks of the LSCS construction process.

4. Implementation of Knowledge Management to Design Tasks

4.1 Functions of Knowledge Management System for Design Tasks

The proposed design knowledge management system aims to facilitate designers’ access to tacit knowledge. Tacit knowledge is captured in various forms, such as work proceedings or minutes, presentation materials, informal documents containing analysis or calculation results, or email correspondence files. Captured tacit knowledge is connected to related explicit knowledge captured as documents published in a prescribed format. The functions implemented to achieve the aims of the design knowledge management system are as listed in Table 3.

4.2 Screen Composition for Knowledge Management System for Design Tasks

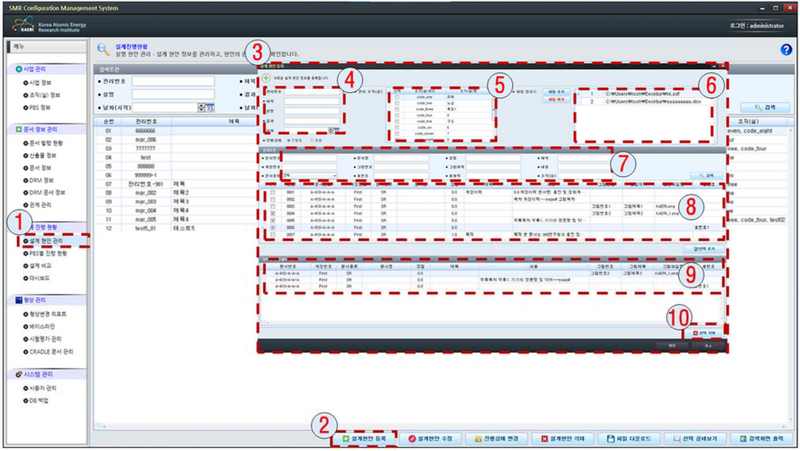

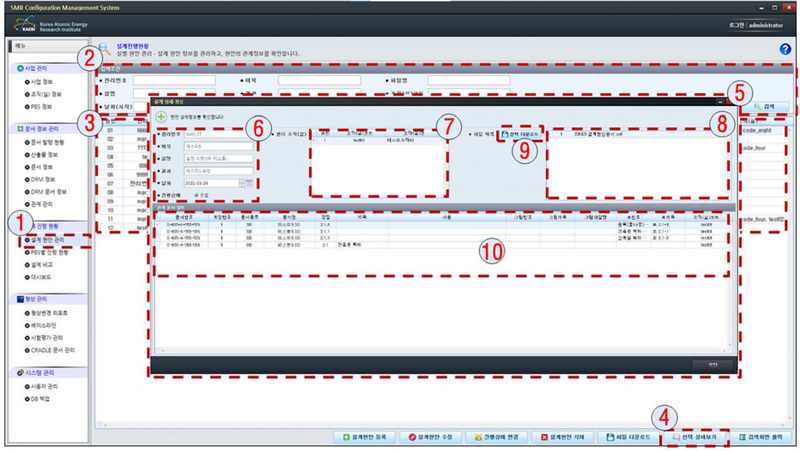

This section explains the screens that implement the main functions of knowledge management system listed in Table 2. The bullets written to explain the screen and operation sequence described in Section 4.2.1-4.2.3 are identical to the numbers expressed in Figure 4-Figure 6.

The design information in the documents published in a prescribed format was stored in the proposed system. Because only the stored content is displayed, the information expected to be searched is derived in advance to avoid omissions during the input.

The screens for inputting issue-related information and tacit knowledge are shown in Figure 4 and Figure 5. The procedure for operating the screen is as follows:

① Select the menu “Design issue management.” A design issue refers to dissatisfaction that requires a design change or re-examination during the design statuses and enables the creation of tacit knowledge.

② Click the button “design issue register.”

③ The pop-up screen to input information related to design issue then appears.

④ Input issue-related basic information, such as title, register date, progress period, and progress status.

⑤ Select all engineering fields relevant to the issue.

⑥ Upload tacit knowledge related to the issue (all types of electronic files, such as Excel, Notepad, and Figures etc).

⑦ Enter the search conditions about design information.

⑧ Design information identical to the search conditions are

⑨ displayed. The displayed design information is limited to the saved contents, as described in Section 4.2.1. Select one piece of information that the user wants to connect with issue-related tacit knowledge.

⑩ Selected design information is displayed in the window.

⑪ Click the button “Register.” Design-issue-related basic information and tacit knowledge are registered, and the design information selected as related to tacit knowledge is linked.

⑫ When click the button “Change design issue status,” users can change the progress status of the design issue currently printed in ③.

⑬ If users click the button ⑪ for a design issue in the “In Progress” status, users can change it to the “Completed” status, and if users click button ⑪ for a design issue in the “Completed” status, users can change it to the “In Progress” status.

⑭ When users click the “Confirm” button, the progress status changes as described in ⑫.

The screen to search for detailed tacit knowledge and download materials is shown in Figure 6. The issue-related tacit knowledge that can be searched is limited to the content saved, as explained in Section 4.2.2. The procedure for operating the screen is as follows:

① Select the menu “Design issue management.”

② Enter the search conditions. The search conditions included issue title, related engineering fields, progress period, and progress status.

③ The Issue related information identical to the search condition is displayed.

④ Select one of the issues searched in ③ and click the button “issue information details”

⑤ A pop-up screen was used to display detailed information regarding the selected design issue.

⑥ The issue-related basic information saved according to the procedure ④ in Section 4.2.2 is displayed.

⑦ The issue-related engineering fields saved according to the procedure ⑤ in Section 4.2.2 is displayed.

⑧ The issue-related tacit knowledge registered as a form of electronic files saved according to the procedure ⑥ in Section 4.2.2 is displayed.

⑨ Click the button “Download.” Users can obtain issue-related tacit knowledge by downloading electronic files.

⑩ The issue-related design information saved according to the procedure described in Section 4.2.2 is displayed.

5. Conclusion

It was confirmed that tacit knowledge is important for improving the technical understanding of tasks and preserving technical skills among members. It is necessary to apply the concept of knowledge management to systematically manage and effectively utilize tacit knowledge.

In this study, a knowledge management system is proposed to technically support design tasks by applying it to the design stage of the LSCS construction. The proposed system was implemented to store tacit knowledge produced without a format, facilitate retrieval, and define the relationship between tacit knowledge and design results in documents produced officially. This system was also implemented to expand the transfer of tacit knowledge from a small number of individuals to all organization members.

This could improve accessibility to tacit knowledge by allowing anyone who needs tacit knowledge to use it, and it is expected to promote the progress of design work by helping in the understanding of design results and changes that are difficult to understand using only existing published documents.

In the proposed system, the capture process depends on the by-products derived from the work process. Therefore, if guidelines for the level and method of tacit knowledge capture are attached to this system, the effectiveness of knowledge management is expected to increase significantly. From an organizational perspective, an organization is expected to maintain its technological capabilities by continuously managing its valuable tacit knowledge.

Author Contributions

Conceptualization, S. M. LEE; Methodology, S. M. LEE and Y. H. Kim; Software, Y. H. Kim, J. S. Oh; Validation, Y. H. Kim, J. S. Oh, C. S. Ha; Writing—Original Draft Preparation, S. M. Lee; Writing—Review & Editing, S. M. Lee; Visualization, Y. H. Kim; Supervision, S. M. Lee and C. S. Ha.

References

-

P. P. Groumpos, “Large scale systems and fuzzy cognitive maps: A critical overview of challenges and research opportunities,” Annual Reviews in Control, vol. 38, pp. 93-102, 2014.

[https://doi.org/10.1016/j.arcontrol.2014.03.009]

-

C. Mclnerney, “Knowledge management and the dynamic nature of knowledge,” Journal of the American Society for Information Science and Technology, vol. 53, no. 12, pp. 1009-1018, 2002.

[https://doi.org/10.1002/asi.10109]

-

D. Yu and J. Yang, “Knowledge management research in the construction industry: A review,” Journal of the Knowledge Economy, vol. 9, no. 3, pp. 782-803, 2018.

[https://doi.org/10.1007/s13132-016-0375-7]

- M. Wetherill, Y. Reztui, C. Lima, and A. Zarli, “Knowledge management for the construction industry: The E-COGNOS project,” Journal of Information Technology in Construction, vol. 7, pp. 183-196, 2002.

-

M. Park, Y. Jang, H. Lee, C. Ahn, and Y. Yoon, “Application of knowledge management technologies in Korean small and medium-sized construction companies,” Journal of Civil Engineering, vol. 17, no. 1, pp. 22-32, 2013.

[https://doi.org/10.1007/s12205-013-1607-z]

-

A. M. Serban and J. Luan, “Overview of knowledge management,” New Directions for Institutional Research, vol. 2002, no. 113, pp. 5-16, 2002.

[https://doi.org/10.1002/ir.34]

-

T. Koc, K. Kurt, and A. Akbiyik, “A brief summary of knowledge management domain: 10-year history of the journal of knowledge management,” Procedia Computer Science, vol. 158, pp. 891-898, 2019.

[https://doi.org/10.1016/j.procs.2019.09.128]

- B. Crowley, “Tacit Knowledge and Quality Assurance: Bridging the Theory-Practice Divide,” Knowledge management for the information professional, In T. Srikantaiah and M. Koenig (eds.), Medford N. J.: Information Today Inc., 2002.

- J. J. Kidwell, K. M. Vander Linde, and S. L. Johnson, “Applying corporate knowledge management practices in higher education,” Educause Quarterly, vol. 4, pp. 28-33, 2002.